OEM kev cai stainless hlau casting twj tso kua mis lub cev nrogCNC machining cov kev pab cuamthiab kev kho cua sov kev pab cuam los ntawm Tuam Tshoj casting foundry.

Stainless hlau muaj qhov tsawg kawg nkaus Cr ntsiab lus ntawm 11.5%, thiab lwm yam hlau alloy xws li Ni thiab Mo, ua rau nws resistant rau corrosive kua ib puag ncig thiab oxidation. Nws muaj kev tiv thaiv corrosion siab thiab hnav tiv taus kev ua yeeb yam, muab kev ua haujlwm zoo heev, thiab tseem paub zoo rau nws qhov zoo nkauj.Stainless hlau peev castingsyog "corrosion-resistant" thaum siv nyob rau hauv cov kua ib puag ncig thiab vapors hauv qab 1200 ° F (650 ° C) thiab "heat-resistant" thaum siv saum toj no kub.

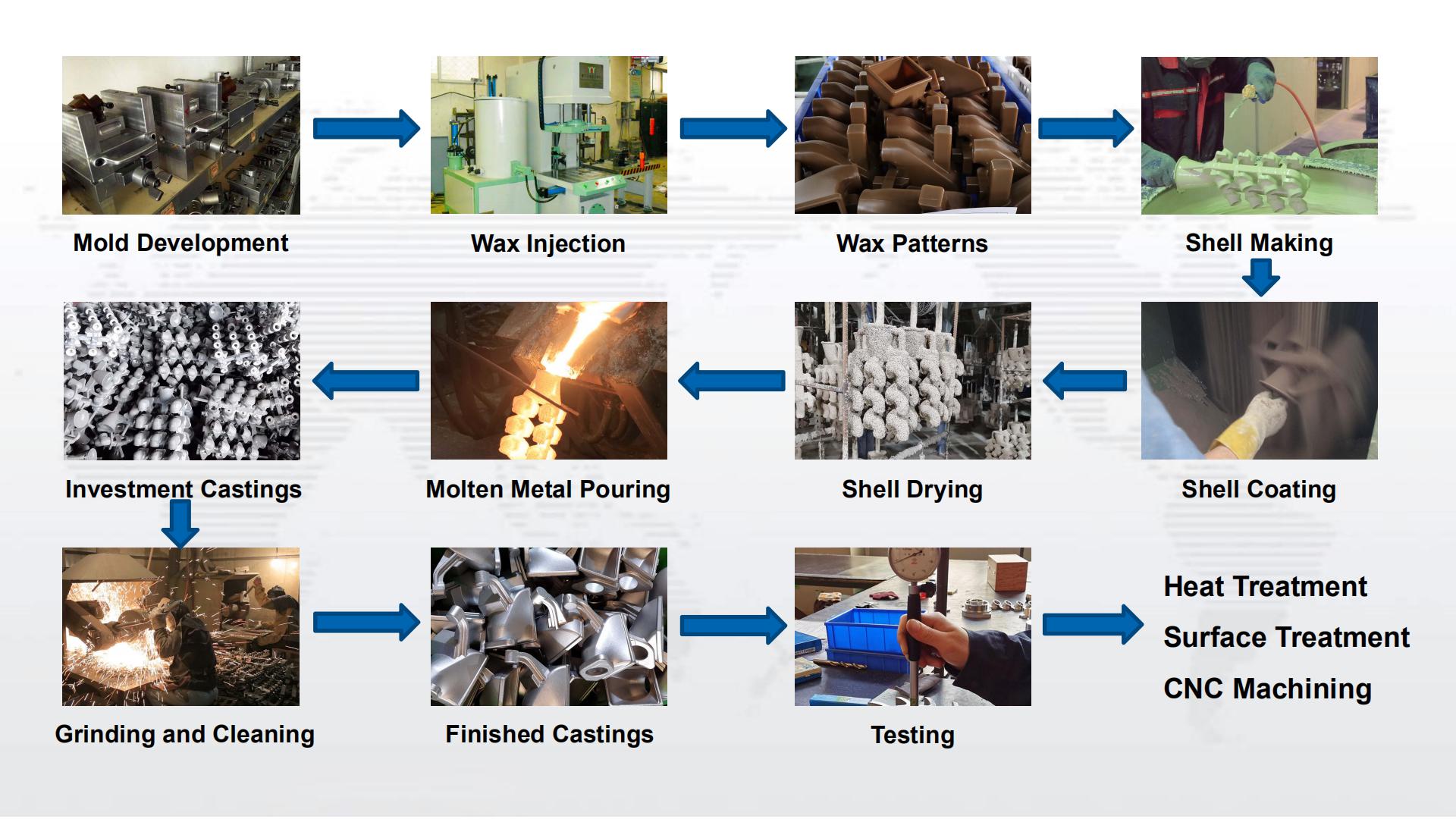

Silica sol casting txheej txheem yog lub ntsiabsteel peev casting txheej txheemntawm RMC peev casting foundry. Peb tau tsim cov thev naus laus zis tshiab ntawm cov khoom siv nplaum kom ua tiav cov khoom siv hluav taws xob ntau dua thiab siv tau zoo los tsim cov slurry plhaub. Nws yog ib qho kev sib tw dhau los uas Silica sol casting txheej txheem hloov cov txheej txheem dej iav tsis zoo, tshwj xeeb tshaj yog rau stainless hlau casting thiaballoy hlau casting. Dhau li ntawm cov khoom siv molding tshiab, silica sol casting txheej txheem kuj tau tsim kho kom ruaj khov thiab tsis tshua muaj cua sov.

| Cov ntaub ntawv rau kev nqis peev Casting txheej txheem ntawm RMC Foundry

| |||

| Qeb | Tuam Tshoj Qib | US Qib | Lub teb chaws Yelemees Qib |

| Ferritic Stainless hlau | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless hlau | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic stainless hlau | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 1.4406, 1.4406, 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, ib. |

| Precipitation Hardening Stainless hlau | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 ib |

| Duplex Stainless Hlau | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 TZS |

| Siab Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Cov cuab yeej hlau | Cr 12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Thaum tshav kub kub Resistant hlau | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 TZS |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, TSI 600, TIAB SA 625 | 2.4815, 2.4879, 2.4680 | |

| Aluminium Alloy | ZL101, ZL102, ZL104 | Txuj: ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Copper Alloy | H96, H85, H65, Hpb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Qib 31 | 2.4778 ib | |