RMC yog Tuam Tshoj stainless hlau casting qhov chaw kom muaj stainless hlau castings machined raws li koj kos duab thiab yuav tsum tau, siv rau npauj npaim valve disc.

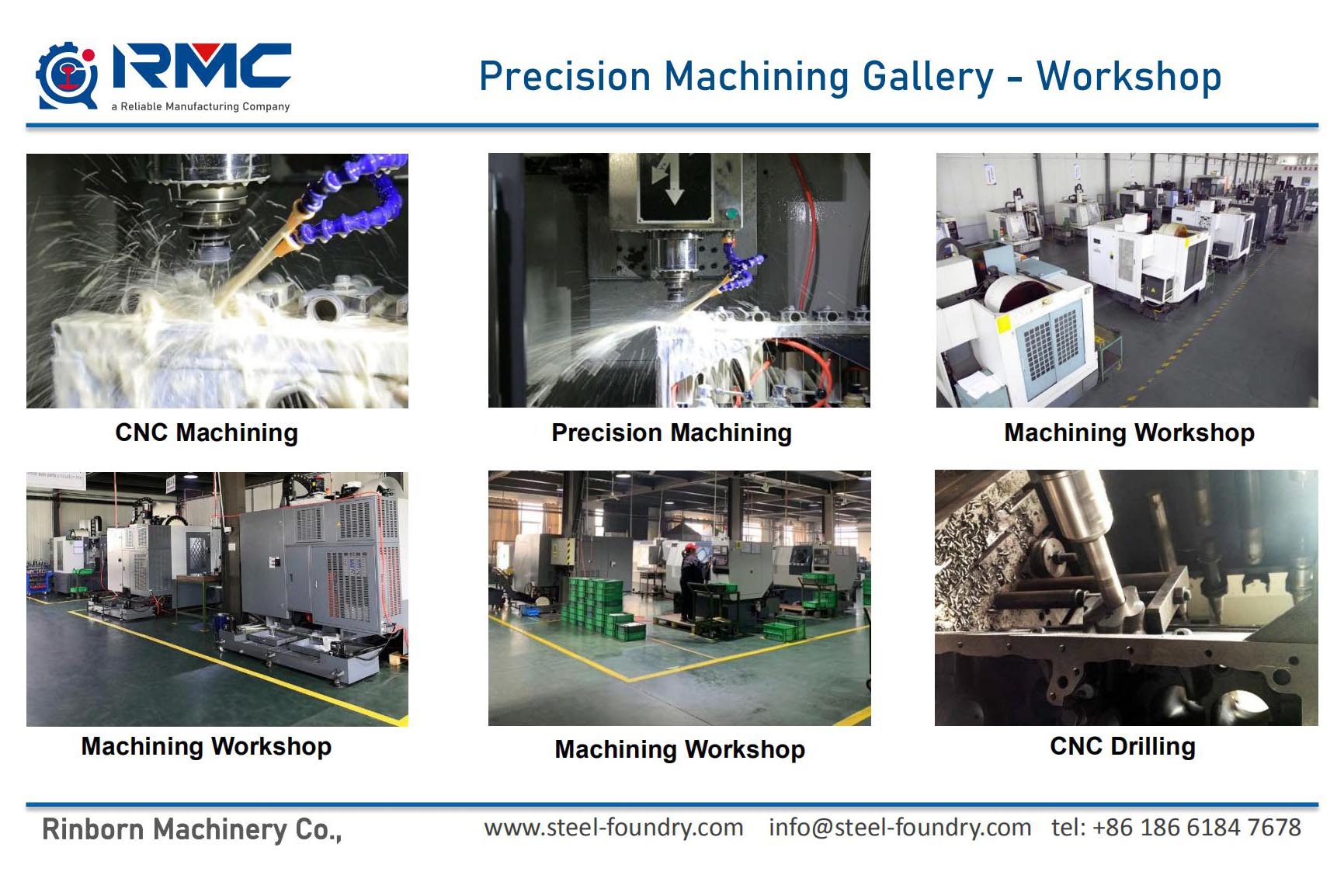

CNC machining yog hais txog cov txheej txheem machining pib los ntawm Computerized Numberical Control (CNC luv luv). Nws yog pab los ntawm CNC kom ncav cuag qhov tseeb thiab ruaj khov nrog cov nqi zog tsawg. Machining yog ib yam ntawm ntau yam txheej txheem uas ib daim ntawm raw khoom yog txiav mus rau hauv ib tug xav tau kawg cov duab thiab loj los ntawm ib tug tswj cov khoom-tshem tawm txheej txheem. Cov txheej txheem uas muaj cov ntsiab lus no, tswj cov khoom tshem tawm, yog niaj hnub no suav nrog kev tsim khoom tsim tawm, sib txawv los ntawm cov txheej txheem ntawm kev tswj cov khoom siv ntxiv, uas yog hu ua additive manufacturing.

Raws nraim li qhov "tswj" ib feem ntawm lub ntsiab lus txhais tau txawv, tab sis nws yuav luag txhua zaus siv cov cuab yeej siv tshuab (ntxiv rau cov cuab yeej hluav taws xob thiab cov cuab yeej tes). Qhov no yog txheej txheem siv los tsim ntau yam khoom siv hlau, tab sis nws kuj tuaj yeem siv rau ntawm cov ntaub ntawv xws li ntoo, yas, ceramic, thiab cov khoom sib xyaw. CNC machining npog ntau yam txheej txheem xws li milling, tig, lathing, drilling, honing, sib tsoo ... thiab lwm yam.

| CNC Precision Machining Muaj peev xwm | ||||

| Cov chaw | Ntau | Qhov Loj | Muaj peev xwm txhua xyoo | General raug |

| Vertical Machining Center (VMC) | 48set ib | 1500mm × 1000mm × 800mm | 6000 tuj los yog 300000 daim | ± 0.005 |

| Kab rov tav Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | 2000 tons lossis 100000 pieces | ± 0.005 |

| CNC tshuab | 60 sets | Max tig dia. φ600 hli | 5000 tons lossis 600000 daim | |

| Excutive Standard of Casting Tolerance: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) lossis GBT 6414 (Tuam Tshoj). | ||||

Lub chaw machining yog tsim los ntawm CNC milling tshuab. Qhov sib txawv loj tshaj plaws los ntawm CNC milling tshuab yog tias lub chaw machining muaj peev xwm hloov pauv cov cuab yeej machining. Los ntawm kev txhim kho cov cuab yeej rau lub hom phiaj sib txawv ntawm cov cuab yeej magazine, cov cuab yeej machining ntawm lub spindle tuaj yeem hloov tau los ntawm cov cuab yeej hloov pauv tsis siv neeg hauv ib lub clamping kom paub ntau yam machining nta.

CNC machining chaw yog lub tshuab ua haujlwm siab ua haujlwm zoo uas yog tsim los ntawm cov cuab yeej siv tshuab thiab CNC system thiab tsim nyog rau kev ua haujlwm nyuaj. CNC machining chaw yog tam sim no yog ib qho ntawm feem ntau siv CNC tshuab cuab yeej nyob rau hauv lub ntiaj teb no nrog muaj zog ua tiav muaj peev xwm. Nws tuaj yeem ua tiav cov ntsiab lus ua tiav ntau dua tom qab lub workpiece clamped ib zaug. Kev ua kom raug yog siab. Rau batch workpieces nrog nruab nrab ua nyuaj nyuaj, nws efficiency yog 5-10 lub sij hawm ntawm cov cuab yeej zoo tib yam, tshwj xeeb tshaj yog nws muaj peev xwm ua tiav Ntau yam uas tsis tuaj yeem ua tiav los ntawm cov cuab yeej zoo tib yam yog tsim nyog rau ib qho kev ua haujlwm nrog ntau cov duab thiab cov kev xav tau siab los yog rau me me thiab nruab nrab batch ntau lawm ntau yam. Nws tsom rau kev ua haujlwm ntawm milling, tho txawv, drilling, tapping thiab txiav xov ntawm ib lub cuab yeej, kom nws muaj ntau yam kev siv tshuab.

Machining chaw muab faib rau hauv kab rov tav thiab ntsug machining chaw raws li lawv txoj haujlwm spatial thaum spindle machining. Muab faib raws li txheej txheem siv: tho txawv thiab milling machining chaw, compound machining chaw. Raws li kev faib tshwj xeeb ntawm kev ua haujlwm, muaj xws li: ib leeg workbench, ob chav workbench thiab multi-workbench machining chaw. Machining chaw nrog ib leeg-axis, dual-axis, peb-axis, plaub-axis, tsib-axis thiab interchangeable headstocks, thiab lwm yam.

CNC machining yog hom precision machining los ntawm CNC tshuab xws li advanced machining chaw uas muaj sab saum toj kawg 5 axis machining chaw, 4 axis ob chav platform machining chaw, los yog CNC tig lathes uas kuj yuav tsim tau rau CNC tig chaw muaj peev xwm hloov tau ntau dua. ntau tshaj 15 cutters nyob rau hauv ib tug tuav hloov; CNC milling tshuab thiab CNC drilling thiab tapping cov chaw.Precision machining ntawm steel casting yog txawv ntawm machining ntawm steel profile. Precision casting twb ua tiav cov duab zoo heev ntawm qhov xav tau, yog li nws txuag ntau ntawm machining piv nrog machining los ntawm steel profile ncaj qha. Tsis tas li vim yog vim li cas, peb feem ntau yuav tsum xav txog qhov chaw ua haujlwm thiab cov nyiaj ua haujlwm zoo ua ntej casting. Peb qhov kev yuav khoom tsis tu ncua yog ua haujlwm tawm cov duab kos duab nrog rau kev kos duab kos duab kom meej meej machining cheeb tsam thiab machining nyiaj pub dawb ntawm daim duab.

RMC peev casting foundry tau nruab nrog 4 axis machining chaw, 15 teeb ntawm CNC tig lathes thiab 3 txheej ntawm cnc milling tshuab, nrog rau kev pab ntau yam tig, milling, tapping, drilling thiab sib tsoo tshuab, peb muaj peev xwm ntawm machining ze li ntawm tag nrho cov. hom steel castings.

| Qib sib npaug ntawm Cast Alloy Steel los ntawm kev lag luam sib txawv | |||||||||

| Pawg | AISI | W-stoff | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| Tsawg Alloy Steel | ib 9255 | 1.0904 ib | 55 ib 7 | 250 Ib 53 | 2090 ua | 55s 7 | 56 ib 7 | - | 5 xyi 8 |

| 1335 ib | 1.1167 ib | 36mn 5 | 150m36 ib | 2120 | 40m 5 | 36mn 5 | SMn 438 (H) | - | |

| 1330 ib | 1.1170 Nws | 28 mn6 | 150 M28 | - | 20m 5 | - | SCMn1 | C28 MN | |

| P4 | 1.2341 ib | X6 CrMo 4 | - | - | - | - | - | - | |

| 5 2100 | 1.3505 Nws | 100cr 6 | 534 ua 99 | 2258 ib | 100c 6 | F.131 | SUJ 2 | 100 cr6 | |

| A204 A | 1.5415 | 15 hmo 3 | 1501240 ib | 2912 ib | 15D 3 | 16 hmo 3 | SIB 12 | 16m3 kwm | |

| ib 8620 | 1.6523 ib | 21 NiCrMo 2 | 805m 20 | 2506 ib | 20 NCV 2 | F.1522 | SNCM 220 (H) | 20 NiCrMo2 | |

| ib 8740 | 1.6546 ib | 40 NiCrMo22 | 311-TSI 7 | - | 40 NCV 2 | F.129 | SIB 240 | 40 NiCrMo2 (KB) | |

| - | 1.6587 ib | 17 CrNiMo6 | 820a 16 | - | 18 NCV 6 | 14 NiCrMo13 | - | - | |

| 5132 ib | 1.7033 ib | 34 nc4 | 530 Ib 32 | - | 32c 4 | 35cr 4 | SCr430 (H) | 34Cr4 (KB) | |

| 5 140 | 1.7035 ib | 41cr 4 | 530a40 ib | - | 42c 2 | 42cr 4 | SCr 440 (H) | 40 cr4 | |

| 5 140 | 1.7035 ib | 41cr 4 | 530a40 ib | - | 42c 2 | 42cr 4 | SCr 440 (H) | 41 cr4 kwb | |

| 5 140 | 1.7045 ib | 42cr 4 | 530a40 ib | 2245 ib | 42 C 4 TS | F.1207 | SIB 440 | - | |

| 5 115 | 1.7131 ib | 16 NcR 5 | (527M 20) : kuv. | 2511 ib | 16 mc5 | F.1516 | - | 16MnCr5 | |

| 5155 ib | 1.7176 ib | 55cr 3 | 527a60 ib | 2253 ib | 55c 3 | - | SUP 9 (A) | 55cr 3 | |

| 4 130 | 1.7218 ib | 25 CrMo4 | 1717 AWV 110 | 2225 | 25 cd4 | F.1251/55Cr3 | SCM 420 / SCM 430 TSI | 25CrMo4 (KB) | |

| 4135 (4137) hnub | 1.7220 Nws | 35 CrMo4 | 708 ib 37 | 2234 ib | 35cd 4 | 34 CrMo4 | SIB 432 | 34CrMo4KB | |

| 4142 ib | 1.7223 ib | 41 CrMo 4 | 708m40 ib | 2244 ib | 42 CD 4 TS | 42 CrMo 4 | SIB 440 | 41 CrMo 4 | |

| 4 140 | 1.7225 ib | 42 CrMo 4 | 708m40 ib | 2244 ib | 40 cd4 | F.1252 | SIB 440 | 40 CrMo4 | |

| ib 4137 | 1.7225 ib | 42 CrMo 4 | 708m40 ib | 2244 ib | 42cd 4 | F.1252 | SIB 440 | 42CrMo4 | |

| A387 12-2 | 1.7337 ib | 16 CrMo4 4 | 1501620 ib | 2216 | 15 CD 4.5 | - | - | 12 ZPO 910 | |

| - | 1.7361 ib | 32 CrMo12 | 722m24 ib | 2240 | 30 cd12 | F.124.A | - | 30 CrMo12 | |

| A182 F-22 | 1.7380 ib | 10 CrMo9 10 | 1501622 ib | 2218 ib | 12 Ib., 9, 10 | F.155 / TU.H | - | 12 CrMo9 10 | |

| 6 150 | 1.8159 ib | 50 ncv 4 | 735a50 ib | 2230 ib | 50 cv4 | F.143 | PAB 10 | 50cwv 4 | |

| - | 1, 8515 | 31 CrMo12 | 722m24 ib | 2240 | 30 cd12 | F.1712 | - | 30 CrMo12 | |

| - | - | - | - | - | - | - | - | - | |

| Nruab nrab Alloy Steel | W1 | 1.1545 Nws | C105W1 | BW1A | Xyoo 1880 | yog 105 | F.5118 | SK 3 | C100 UA |

| L3 | 1.2067 Nws | 100 cr6 | BL 3 | (2140) | Y100C 6 | F.520 L | - | - | |

| L2 | 1.2210 Nws | 115 ZPO 3 | - | - | - | - | - | - | |

| P20 + S | 1.2312 ib | 40 CrMnMoS 8 6 | - | - | 40 CMD 8 + S | X210CrW12 | - | - | |

| - | 1.2419 Nws | 105 AWV 6 | - | 2140 | 105 AWV 13 | F.5233 | SIB 31 | 107 AWV 5 | |

| O1 | 1.2510 Nws | 100 MnCrW 4 | BO 1 | - | 90mnwv 5 | F.5220 | (SK53) | 95MnWCr5KU | |

| S1 | 1.2542 ib | 45 AWV 7 | BS 1 | 2710 ib | 55 wb 20 | F.5241 | - | 45 AWV8 | |

| ib 4340 | 1.6582 ib | 34 NCV 6 | 817m 40 | 2541 ib | 35 NCV 6 | F.1280 Nws | TIAB SA 447 | 35 NiCrMo6KB | |

| 5 120 | 1.7147 ib | 20 MnCr 5 | - | - | 20 mc5 | - | - | - | |

| - | - | - | - | - | - | - | - | - | |

| Tool thiab High Alloy Steel | D3 | 1.2080 Nws | X210 Cr 12 | BD 3 | 2710 ib | Z200 C 12 | F.5212 | SKD 1 | X210Cr13KU |

| P20 | 1.2311 ib | 40 CrMnMo 7 | - | - | 40 ZPO 8 | F.5263 | - | - | |

| H13 | 1.2344 ib | X40CrMoV 5 1 | BH13 | 2242 ib | Z40 CDV 5 | F.5318 | SIB 61 | X40CrMoV511KU | |

| A2 | 1.236 3 | X100 CrMoV 5 1 | BA 2 | 2260 | Z100 CDV 5 | F.5227 | SKD 12 | X100CrMoV51KU | |

| D2 | 1.2379 ib | X155 CrMoV 12 1 | BD 2 | 2310 ib | Z 160 CDV 12 | F.520.A | SKD 11 | X155CrVMo121KU | |

| D4 (D6) | 1.2436 ib | X210 CrW 12 | BD 6 | 2312 ib | Z200 CD 12 | F.5213 | SKD 2 | X215CrW121KU | |

| H21 | 1.2581 Nws | Tx30WCrV9 3 | BH 21 | - | Z30 WCV 9 | F.526 | SKD 5 | X30WCrV 9 3 KU | |

| L6 | 1.2713 ib | 55 NiCrMoV 6 | - | - | 55 NCV 7 | F.520.S | SKT 4 | - | |

| M 35 | 1.3243 ib | S6/5/2/5 | BM 35 | ib 2723 | 6-5-2-5 | F.5613 | TSI 55 | HS6-5-5 | |

| M 2 | 1.3343 ib | S6/5/2 | BM 2 | 2722 ib | Z85 WDCV | F.5603 | SIB 51 | HS6-5-2-2 | |

| M 7 | 1.3348 ib | S2/9/2 | - | 2782 ib | 29 2 | - | - | NWS 2-9-2 | |

| HWM 3 | 1.4718 ib | Tx45CrSi 9 3 | 401 Ib. 45 | - | Z45 CS 9 | F.3220 | SUH 1 | X45CrSi8 | |

| - | 1.7321 ib | 20 ZPO 4 | - | 2625 ib | - | F.1523 | - | 30 CrMo4 | |

| High Tensile Strength Steel | A128 (A) | 1.3401 Nws | G-X120 Mn 12 | BW10 | 2183 ib | Z120 M 12 | f.825 1 | SCMnH 1 | GX120Mn12 |

Peev xwm ntawmKev nqis peev Casting Foundry:

• Max Loj: 1,000 mm × 800 mm × 500 mm

• Qhov hnyav: 0.5 kg - 100 kg

• Ib xyoos twg muaj peev xwm: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Dej iav thiab lawv cov khoom sib tov.

• Tolerances: Thaum Thov.

Qhov zoo ntawmKev nqis peev Casting Cheebtsam:

- Zoo heev thiab du nto tiav

- Tight dimensional tolerances.

- Cov duab sib txawv thiab sib txawv nrog kev tsim qauv yooj yim

- Muaj peev xwm cam khwb cia nyias phab ntsa yog li ib tug sib zog casting tivthaiv

- Kev xaiv dav ntawm cam khwb cia hlau thiab alloys (ferrous thiab non-ferrous)

- Cov qauv tsis tas yuav tsum muaj nyob rau hauv kev tsim pwm.

- Txo qhov xav tau rau kev ua haujlwm thib ob.

- Cov khoom siv tsawg tsawg.

| Khoom siv rau kev nqis peev Casting thiabCNC Machiningntawm RMC Foundry | |||

| Qeb | Tuam Tshoj Qib | US Qib | Lub teb chaws Yelemees Qib |

| Ferritic Stainless hlau | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless hlau | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic stainless hlau | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 1.4406, 1.4406, 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, ib. |

| Precipitation Hardening Stainless hlau | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 ib |

| Duplex Stainless Hlau | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 TZS |

| Siab Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Cov cuab yeej hlau | Cr 12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Thaum tshav kub kub Resistant hlau | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 TZS |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, TSI 600, TIAB SA 625 | 2.4815, 2.4879, 2.4680 | |

| Aluminium Alloy | ZL101, ZL102, ZL104 | Txuj: ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Copper Alloy | H96, H85, H65, Hpb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Qib 31 | 2.4778 ib | |

Kuj hu ua precision machining, CNC machining tuaj yeem ncav cuag qhov raug siab heev hauv geometical kam rau ua thiab qhov ntev ntev. Nrog peb cov tshuab CNC thiab Kab rov tav Machining Centers (HMC) thiab Vertical Machining Centers (VMC), peb tuaj yeem ua tau raws li tag nrho koj cov qib siab kam rau ua.

| INVESTMENT CASTING TOLERANCES | |||

| Ntiv | millimeters | ||

| Dimension | Ua siab ntev | Dimension | Ua siab ntev |

| Mus txog 0.500 | ± .004 " | Mus txog 12.0 | ± 0.10 hli |

| 0.500 rau 1.000 " | ± 006 " | 12.0-25.0 Nws | ± 0.15 hli |

| 1.000 rau 1.500 " | ± 008 " | 25.0-37.0 Nws | ± 0.20 hli |

| 1.500 rau 2.000 " | ± .010 " | 37.0-50.0 Nws | ± 0.25 hli |

| 2.000-2.500 " | ± .012 " | 50.0 rau 62.0 | ± 0.30 hli |

| 2.500 rau 3.500 " | ± .014 " | 62.0 rau 87.0 | ± 0.35 hli |

| 3.500 rau 5.000 " | ± .017 " | 87.0 rau 125.0 | ± 0.40 hli |

| 5,000 rau 7,500 " | ± .020 " | 125.0 rau 190.0 | ± 0.50 hli |

| 7.500-10.000 " | ± 022 " | 190.0 rau 250.0 | ± 0.57 hli |

| 10,000 rau 12,500 " | ± .025 " | 250.0 rau 312.0 | ± 0.60 hli |

| 12.500-15.000 Nws | ± 028 " | 312.0 rau 375.0 | ± 0.70 hli |