OEM kev cai stainless hlau castings ua los ntawm poob ciab peev casting thiabCNC machining cov kev pab cuam. AISI 316 / CF8M stainless hlau yog dav siv los tsim cov twj tso kua mis stainless hlau vaj tse lossis kawg npog vim nws qhov kev ua tau zoo los tiv thaiv xeb.

Stainless hlau muaj qhov tsawg kawg nkaus chromium cov ntsiab lus ntawm 10.5%, ua rau nws tiv taus ntau dua rau corrosive kua ib puag ncig thiab rau oxidation. Nws yog corrosion kuj heev resistant thiab hnav resistant, muab zoo heev machinability, thiab yog paub zoo rau nws zoo nkauj tsos. Stainless hlau peev castings yog "corrosion-resistant" thaum siv nyob rau hauv cov kua ib puag ncig thiab vapors hauv qab 1200 ° F (650 ° C) thiab "heat-resistant" thaum siv saum toj no kub.

Lub hauv paus alloy cov ntsiab lus ntawm ib qho nickel-base lossis stainless hlau peev casting yog chromium, nickel, thiab molybdenum (los yog "moly"). Peb cov khoom no yuav txiav txim siab qhov casting cov qauv nplej thiab cov khoom siv kho tshuab thiab yuav yog qhov tseem ceeb hauv kev tsim cov peev txheej los tiv thaiv tshav kub, hnav, thiab corrosion.

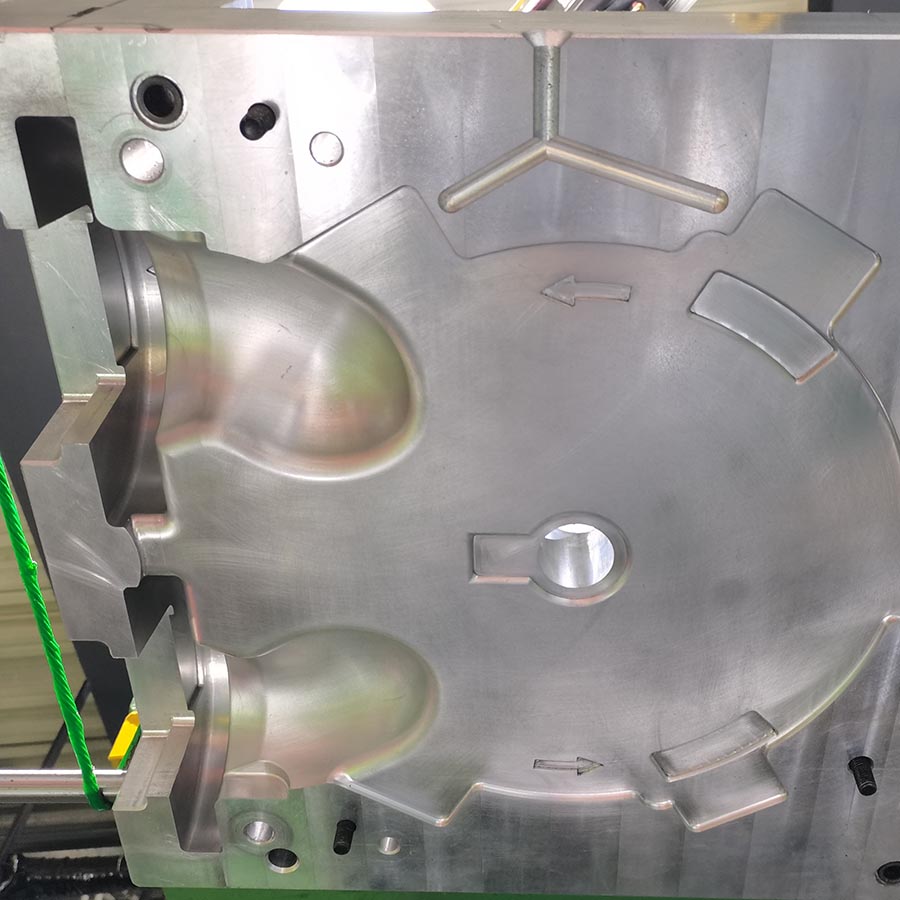

Peb lub Hoobkas tuaj yeem tsim khoomkev cai stainless hlau peev castingsuas phim koj cov qauv tsim tshwj xeeb. Rau qhov nruab nrab ntawm kaum ntawm grams mus rau kaum ntawm kilograms los yog ntau tshaj, peb muab nruj tolerances thiab zoo ib yam rau ib feem ntawm repeatability.

Feem ntau, stainless hlau yuav tsum tau cam khwb cia los ntawm lubpeev precision casting txheej txheemnrog silica sol raws li daim ntawv cog lus. Stainless hlau silica sol castings muaj qib siab ntawm precision nto thiab kev ua tau zoo.

Vim nws cov khoom tshwj xeeb ntawm lub cev, stainless hlau castings yog nrov nyob rau hauv ntau yam kev siv, tshwj xeeb tshaj yog nyob rau hauv ib puag ncig hnyav. Kev lag luam zoo rau stainless hlau peev castings muaj xws li roj thiab roj, kua zog, kev thauj mus los, hydraulic systems, zaub mov kev lag luam, kho vajtse thiab xauv, kev ua liaj ua teb ... thiab lwm yam.

▶ Muaj peev xwm ntawmKev nqis peev Casting Foundry

• Max Loj: 1,000 mm × 800 mm × 500 mm

• Qhov hnyav: 0.5 kg - 100 kg

• Ib xyoos twg muaj peev xwm: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Dej iav thiab lawv cov khoom sib tov.

• Tolerances: Thaum Thov.

▶ Cov txheej txheem tseem ceeb ntawm kev nqis peev Casting

• Patterns & Tooling Design → Hlau Tuag Ua → Ciab Txhaj → Slurry Assembly → Shell Building → De-Waxing → Chemical Composition Analysis → Melting & Pouring → Cleaning, Grinding & Shot Blasting → Post Processing or Packing for Shipment

▶ Peb Tshawb Fawb Li CasPoob Wax Castings

• Spectrographic thiab phau ntawv txheeb xyuas kom muaj nuj nqis

• Metallographic tsom xam

• Brinell, Rockwell thiab Vickers hardness tshuaj xyuas

• Kev tshuaj xyuas cov cuab yeej cuab tam

• Kev ntsuas qhov kub thiab txias tsis zoo

• Kev tshuaj xyuas huv

• UT, MT thiab RT tshuaj xyuas

▶ Cov txheej txheem tom qab Casting

• Deburring & Ntxuav

• Txhaj Tshuaj Txhaum / Xuab zeb Peening

• Kev kho cua sov: Normalization, Quench, Tempering, Carburization, Nitriding

• Kev Kho Hniav: Passivation, Anodizing, Electroplating, Kub Zinc Plating, Zinc Plating, Nickel Plating, Polishing, Electro-Polishing, Painting, GeoMet, Zintec.

• Machining: Tig, Milling, Lathing, Drilling, Honing, Sib Tsoo.

▶ Qhov zoo ntawm Kev nqis peev Casting txheej txheem:

• Zoo heev thiab du nto tiav

• Tight dimension tolerances.

• Cov duab nyuaj thiab sib txawv nrog kev tsim qauv yooj yim

• Muaj peev xwm nrum nyias phab ntsa yog li ntawd ib tug sib zog casting tivthaiv

• Kev xaiv dav ntawm cov hlau cam thiab alloys (ferrous thiab non-ferrous)

• Tsis tas yuav tsim cov qauv tsim pwm.

• Txo qhov xav tau ntawm kev siv tshuab thib ob.

• Cov khoom siv tsawg tsawg.