OEM kev cai spheroidal graphite (SG) ductile nodular cam khwb cia hlau castings los ntawm xuab zeb casting txheej txheem.

Xuab zeb casting yog qhov qub tab sis tseem niaj hnub casting txheej txheem. Nws siv cov xuab zeb ntsuab (cov xuab zeb ntub) los yog cov xuab zeb qhuav los tsim cov txheej txheem molding. Cov xuab zeb ntsuab ntsuab yog cov txheej txheem qub qub uas siv hauv keeb kwm. Thaum ua cov pwm, cov qauv ua los ntawm cov ntoo los yog hlau yuav tsum tau tsim nyob rau hauv thiaj li yuav tsim lub hollow kab noj hniav. Cov hlau molten ces hliv rau hauv kab noj hniav los tsim cov castings tom qab txias thiab solidification. Xuab zeb casting tsis tshua kim dua li lwm cov txheej txheem casting ob qho tib si rau kev tsim pwm thiab chav ua haujlwm casting. Cov xuab zeb casting, ib txwm txhais tau tias ntsuab xuab zeb casting (yog tias tsis muaj lus piav qhia tshwj xeeb). Txawm li cas los xij, niaj hnub no, lwm cov txheej txheem casting kuj tseem siv cov xuab zeb los ua cov pwm. Lawv muaj lawv tus kheej lub npe, xws li plhaub pwm casting, furan resin coated xuab zeb casting (tsis muaj ci hom), poob ua npuas ncauj casting thiab nqus casting.

Dab tsi yog Qhov Zoo ntawmXuab zeb Casting?

✔ Tus nqi qis dua vim nws pheej yig thiab siv tau cov khoom pwm thiab cov cuab yeej tsim khoom yooj yim.

✔ Ntau qhov hnyav ntawm chav tsev los ntawm 0.10 kg txog 500 kgs lossis loj dua.

✔ Ntau yam qauv los ntawm hom yooj yim mus rau hom complex.

✔ Haum rau kev tsim khoom ntawm ntau qhov ntau.

Ductile cam khwb cia hlau, uas tseem hu ua nodular cam khwb cia hlau, spheriodal graphite cam khwb cia hlau los yog SG hlau luv luv, sawv cev rau ib pab pawg neeg ntawm cam khwb cia hlau. Nodular cam khwb cia hlau tau txais nodular graphite los ntawm spheroidization thiab inoculation kev kho mob, uas zoo txhim kho cov neeg kho tshuab zog ntawm cov cam khwb cia hlau, tshwj xeeb tshaj yog cov yas thiab toughness, thiaj li yuav tau txais lub zog siab dua carbon steel.

Cov hlau castings muaj kev poob siab zoo dua li cov hlau, thaum cov hlau castings muaj qhov zoo dua weldability. Thiab rau qee qhov, cov ductile iorn castings tuaj yeem muaj qee qhov kev ua yeeb yam ntawm kev hnav thiab xeb. Yog li cov hlau nplaum hlau tuaj yeem siv rau qee lub twj tso kua mis lossis cov khoom siv dej. Txawm li cas los xij, peb tseem yuav tsum tau ceev faj tiv thaiv lawv ntawm kev hnav thiab xeb.

Ductile hlau tsis yog ib qho khoom siv xwb tab sis yog ib feem ntawm cov khoom siv uas tuaj yeem tsim kom muaj ntau yam khoom los ntawm kev tswj hwm ntawm microstructure. Lub ntsiab lus txhais cov yam ntxwv ntawm pawg ntawm cov ntaub ntawv no yog cov duab ntawm graphite. Hauv cov hlau nplaum, cov graphite yog nyob rau hauv daim ntawv ntawm nodules es tsis yog flakes li nws yog nyob rau hauv grey hlau. Lub ntsej muag zoo nkauj ntawm cov flakes ntawm graphite tsim cov ntsiab lus kev ntxhov siab nyob rau hauv cov hlau matrix thiab cov duab sib npaug ntawm cov nodules tsawg dua, yog li inhibiting kev tsim cov kab nrib pleb thiab muab cov ductility zoo dua uas muab cov hlau nws lub npe. Yog li feem ntau hais lus, yog tias cov hlau nplaum tuaj yeem ua tau raws li koj qhov yuav tsum tau ua, cov hlau nplaum tuaj yeem yog koj thawj qhov kev xaiv, es tsis txhob carbon steel rau koj cov castings.

Cov Khoom Raw Muaj nyob ntawm Sand Casting Foundry ntawm RMC:

• Grey Hlau: GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350

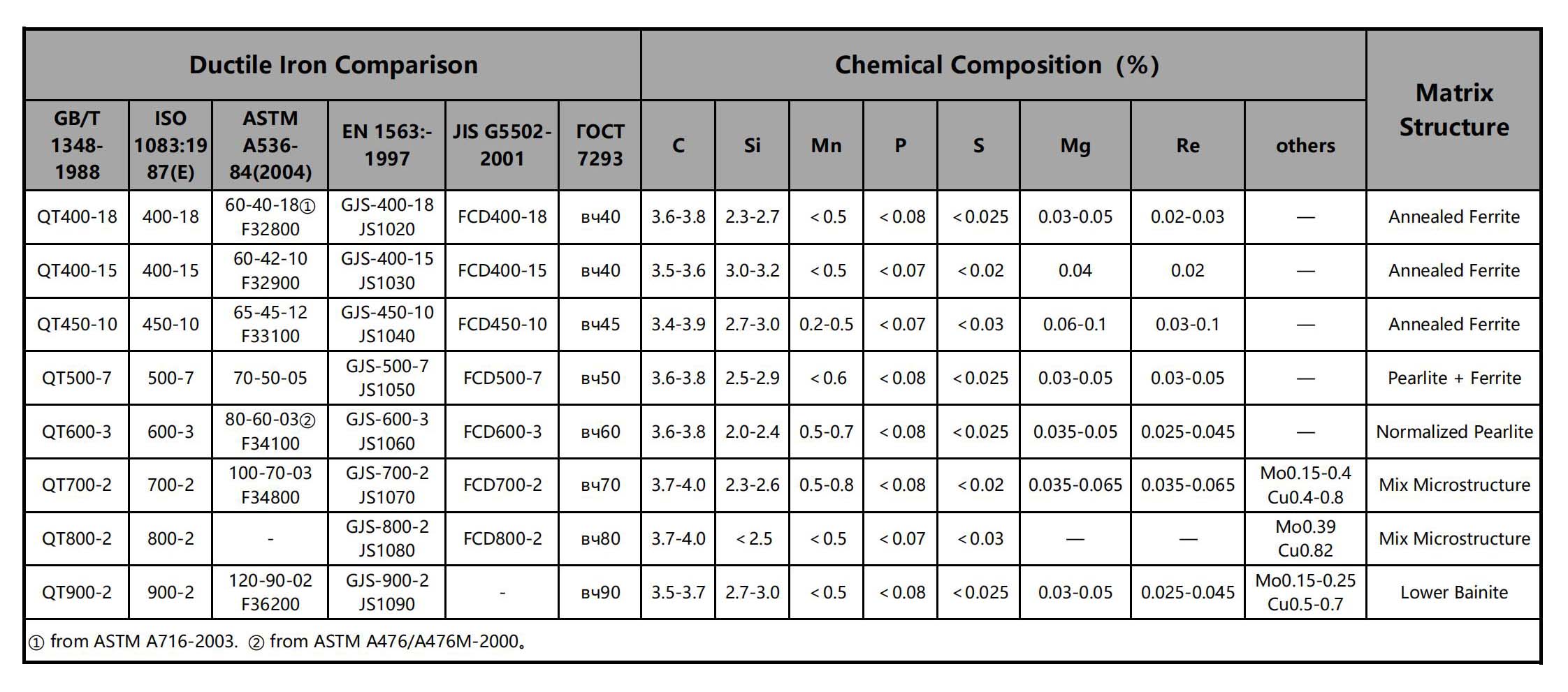

• Cov Hlau Hlau: GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2

• Aluminium thiab lawv cov Alloys

• Lwm yam khoom siv thiab cov qauv raws li kev thov

Muaj peev xwm ntawm Sand Casting molded los ntawm tes:

• Max Loj: 1,500 mm × 1000 mm × 500 mm

• Qhov hnyav: 0.5 kg - 500 kg

• Ib xyoos twg muaj peev xwm: 5,000 tons - 6,000 tons

• Tolerances: Thaum Thov.

Muaj peev xwm ntawm Sand Casting los ntawm Tsis Siv Neeg Moulding Machine:

• Max Loj: 1,000 mm × 800 mm × 500 mm

• Qhov hnyav: 0.5 kg - 500 kg

• Ib xyoos twg muaj peev xwm: 8,000 tons - 10,000 tons

• Tolerances: Thaum Thov.