Tuam Tshoj OEM kev cai carbon steel casting khoom los ntawmpoob ciab peev casting txheej txheem.

| Cast Carbon Steel Qib Sib piv | |||||||||||

| Tsis muaj. | Tuam Tshoj | Nyiv | Teb chaws USA | ISO | Lub teb chaws Yelemees | Fabkis | Russia lub teb chaws | Sweden SS | Tebchaws Askiv | ||

| GB | JIS | ASTM | UNS | DIN | W-Nr. | NF | BS | ||||

| 1 | ZG200-400 (ZG15) | SC410 (SC42) | 415-205 (60-30) hnub. | j03000 ua | 200-400 | TSW-38 | 1, 0416 | - | 15l ua | 1306 ib | - |

| 2 | ZG230-450 (ZG25) | SC450 (SC46) | 450-240 965-35) | j0310 1 | 230-450 Nws | TSW-45 | 1.0446 ib | TIAB SA 230 | 25l ua | 1305 ib | A1 |

| 3 | ZG270-500 (ZG35) | SC480 (SC49) | 485-275 (70-40) hnub. | j0250 1 | 270-480 : kuv | TSW-52 | 1.055 2 | TIAB SA 280 | 35l ua | 1505 | A2 |

| 4 | ZG310-570 (ZG45) | SCC 5 | (80-40) | j0500 2 | - | TSW-60 | 1,055 8 | TIAB SA 320 | 45l ua | 1606 | - |

| 5 | ZG340-640 (ZG55) | - | - | J05000 | 340-550 : kuv | - | - | TIAB SA 370 | - | - | A5 |

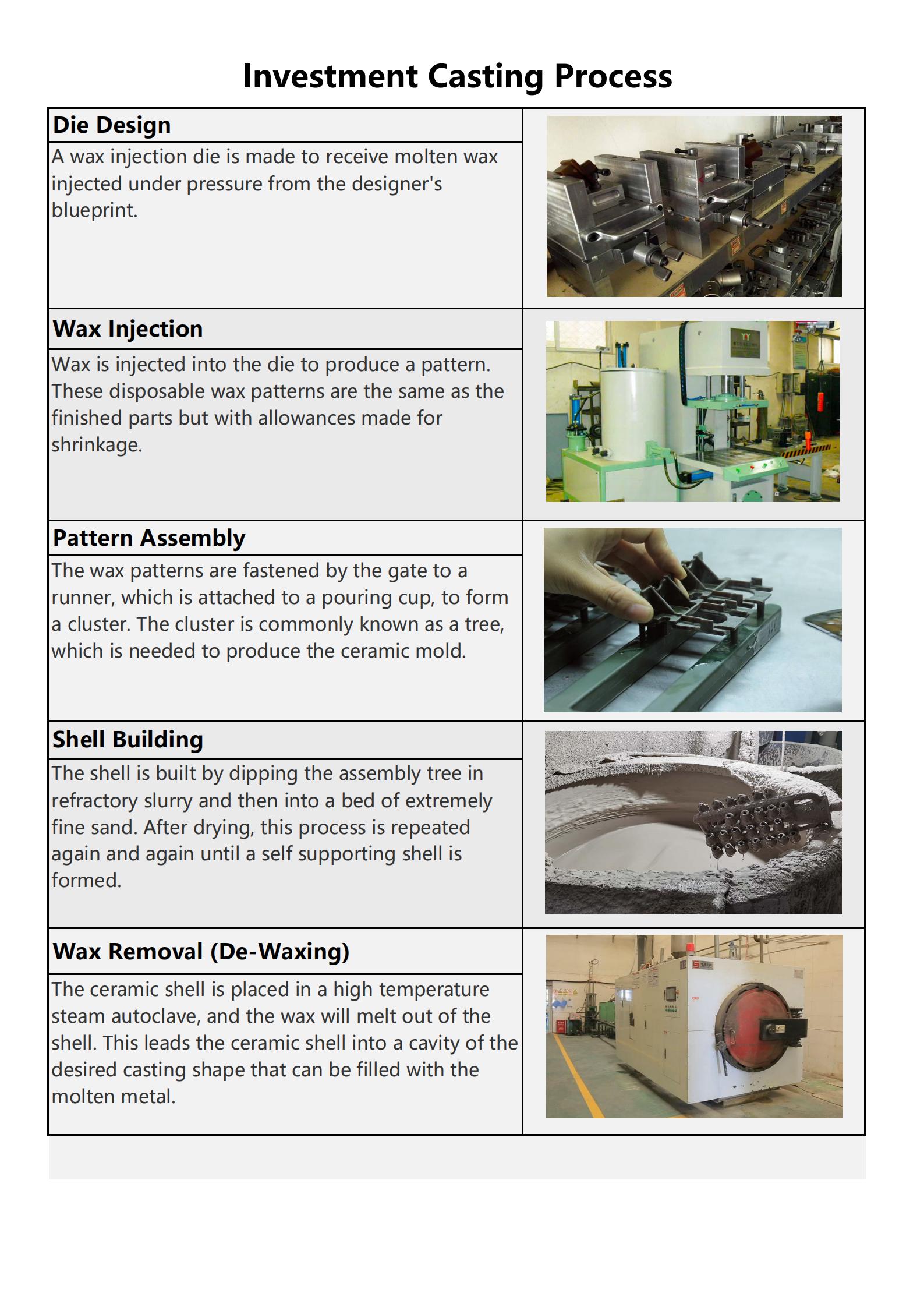

Peev xwm ntawm Peev Casting Foundry:

• Max Loj: 1,000 mm × 800 mm × 500 mm

• Qhov hnyav: 0.5 kg - 100 kg

• Ib xyoos twg muaj peev xwm: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Dej iav thiab lawv cov khoom sib tov.

• Tolerances: Thaum Thov.

Qhov zoo ntawm Kev nqis peev Casting Cheebtsam:

- Zoo heev thiab du nto tiav

- Tight dimensional tolerances.

- Cov duab sib txawv thiab sib txawv nrog kev tsim qauv yooj yim

- Muaj peev xwm cam khwb cia nyias phab ntsa yog li ib tug sib zog casting tivthaiv

- Kev xaiv dav ntawm cam khwb cia hlau thiab alloys (ferrous thiab non-ferrous)

- Cov qauv tsis tas yuav tsum muaj nyob rau hauv kev tsim pwm.

- Txo qhov xav tau rau kev ua haujlwm thib ob.

- Cov khoom siv tsawg tsawg.

| Khoom siv rauKev nqis peev CastingTxheej txheem ntawm RMC Foundry | |||

| Qeb | Tuam Tshoj Qib | US Qib | Lub teb chaws Yelemees Qib |

| Ferritic Stainless hlau | 1Cr17, 022Cr12, 10Cr17, | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Stainless hlau | 1Cr13, 2Cr13, 3Cr13, 4Cr13, | 410, 420, 430, 440B, 440C | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125 |

| Austenitic stainless hlau | 06Cr19Ni10, 022Cr19Ni10, 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 1.4406, 1.4406, 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581, 1.4582, 1.4584, ib. |

| Precipitation Hardening Stainless hlau | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 ib |

| Duplex Stainless Hlau | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 TZS |

| Siab Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Cov cuab yeej hlau | Cr 12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Thaum tshav kub kub Resistant hlau | 20Cr25Ni20, 16Cr23Ni13, 45Cr14Ni14W2Mo | 309, 310, CK20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 TZS |

| Nickle-base Alloy | HASTELLY-C, HASTELLY-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35 -1, TSI 600, TIAB SA 625 | 2.4815, 2.4879, 2.4680 | |

| Aluminium Alloy | ZL101, ZL102, ZL104 | Txuj: ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Copper Alloy | H96, H85, H65, Hpb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobalt-base Alloy | UMC50, 670, Qib 31 | 2.4778 ib | |

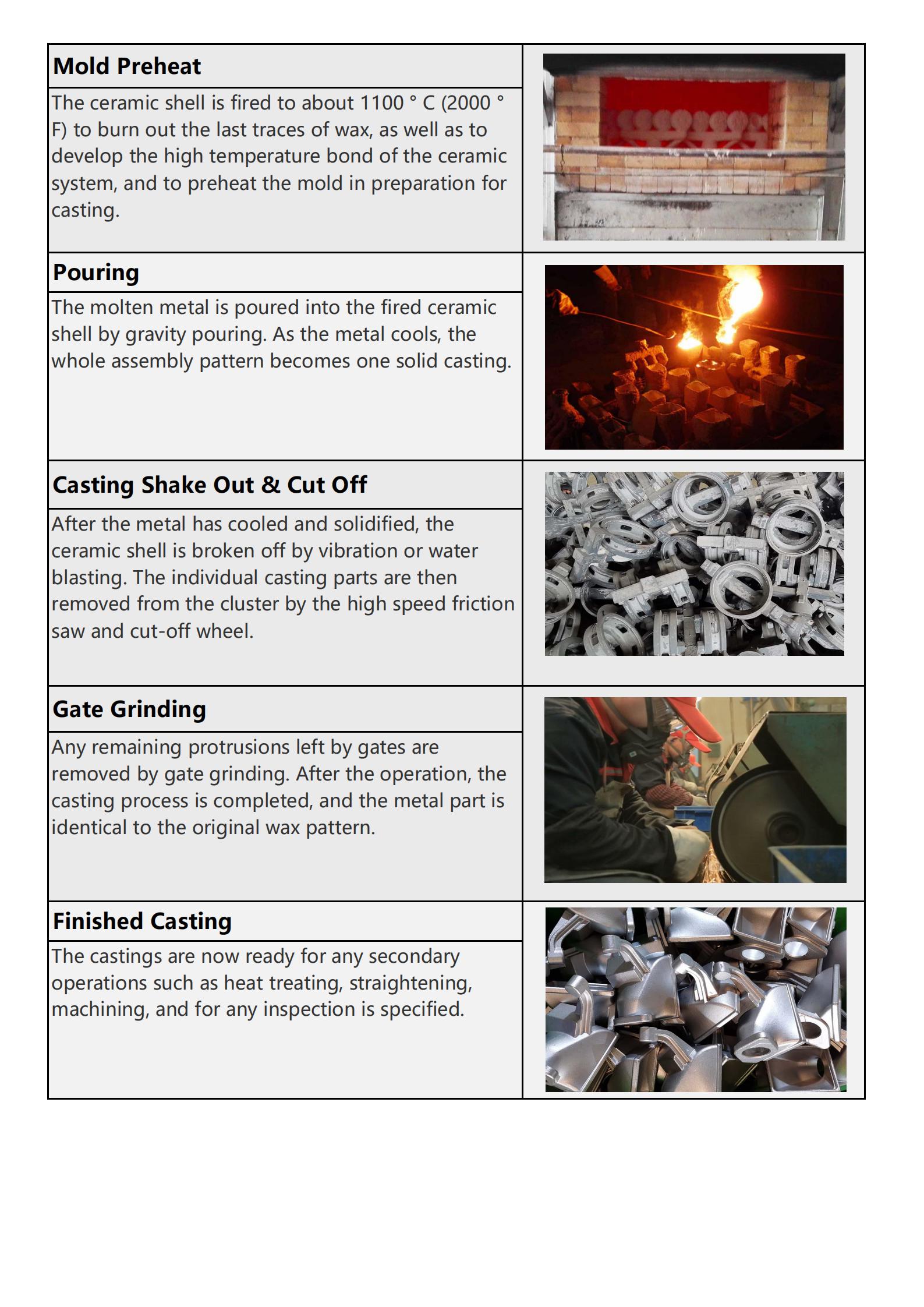

| INVESTMENT CASTING TOLERANCES | |||

| Ntiv | millimeters | ||

| Dimension | Ua siab ntev | Dimension | Ua siab ntev |

| Mus txog 0.500 | ± .004 " | Mus txog 12.0 | ± 0.10 hli |

| 0.500 rau 1.000 " | ± 006 " | 12.0-25.0 Nws | ± 0.15 hli |

| 1.000 rau 1.500 " | ± 008 " | 25.0-37.0 Nws | ± 0.20 hli |

| 1.500 rau 2.000 " | ± .010 " | 37.0-50.0 Nws | ± 0.25 hli |

| 2.000-2.500 " | ± .012 " | 50.0 rau 62.0 | ± 0.30 hli |

| 2.500 rau 3.500 " | ± .014 " | 62.0 rau 87.0 | ± 0.35 hli |

| 3.500 rau 5.000 " | ± .017 " | 87.0 rau 125.0 | ± 0.40 hli |

| 5,000 rau 7,500 " | ± .020 " | 125.0 rau 190.0 | ± 0.50 hli |

| 7.500-10.000 " | ± 022 " | 190.0 rau 250.0 | ± 0.57 hli |

| 10,000 rau 12,500 " | ± .025 " | 250.0 rau 312.0 | ± 0.60 hli |

| 12.500-15.000 Nws | ± 028 " | 312.0 rau 375.0 | ± 0.70 hli |