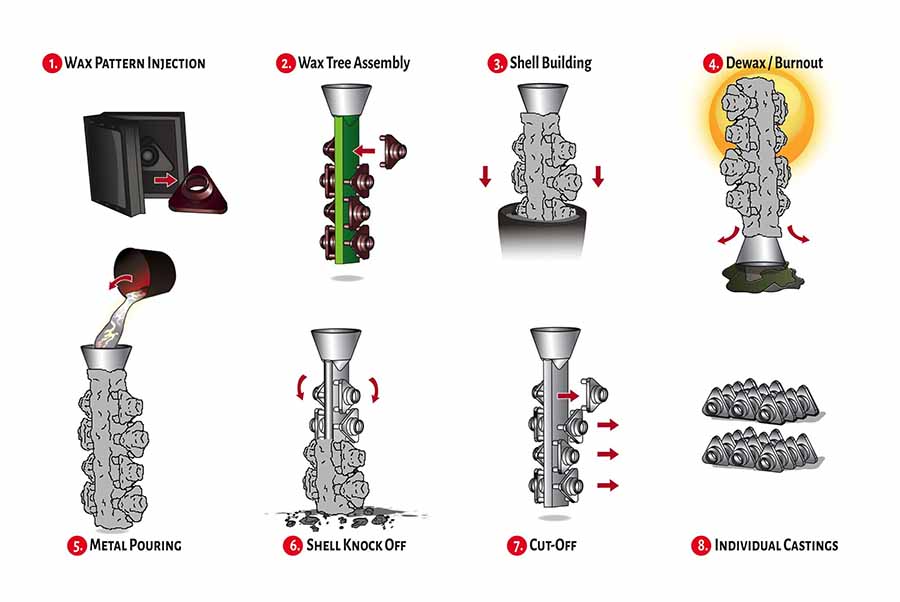

Kev nqis peev castingsiv cov qauv siv quav ciab tsim los ntawm cov cuab yeej tshwj xeeb thiab tshwj xeeb raws li qhov xav tau castings. Cov qauv siv quav ciab (replicas) yog nyob ib puag ncig los ntawm cov khaubncaws sab nraud povtseg ntawm cov ntaub ntawv refractory los tsim lub plhaub muaj zog kom tiv taus cov kub molten hlau thiab alloys. Cov txheej txheem de-wax yuav tshem tawm cov quav ciab kom tso cai rau lub hollow kab noj hniav kom cov hlau molten sau rau lawv los ua qhov xav tau casting qhov chaw. Tias yog vim li cas cov peev casting tseem hu ua poob ciab casting txheej txheem. Nyob rau hauv niaj hnub peev casting foundry, cov ntaub ntawv sib koom ua ke feem ntau yog xa mus rau silica sol thiab iav dej, uas tuaj yeem ua kom zoo ntawm qhov chaw.peev castings. Cov txheej txheem peev casting feem ntau yog siv los tsim cov pa roj carbon steel castings, alloy steel castings,stainless hlau castingsthiab tooj dag castings. Ntawm no hauv tsab xov xwm no, peb sim ua kom paub cov kauj ruam tseem ceeb ntawm peev casting.

Tsim cov cuab yeej rau Kev Txhaum Cai

Raws li qhov xav tau castings thiab txiav txim siab qhov nyiaj pub dawb rau kev ua haujlwm tom qab thiab kev ua tau zoo, cov kws ua haujlwm ntawm peev casting foundry yuav tsum tsim thiab tsim cov pwm hauv cov hlau (uas tseem hu ua "tuag") thiab cov cuab yeej los tsim cov qauv siv quav ciab.

Tsim ib tug Wax Pattern

Hauv niaj hnubpoob ciab casting foundry, cov qauv siv quav ciab feem ntau yog ua los ntawm kev txhaj cov quav ciab rau hauv cov cuab yeej hlau lossis "tuag" nrog cov tshuab txhaj tshuaj tshwj xeeb. Rau ntau qhov castings, ib lub cuab yeej silicon feem ntau yog tsim los ntawm tus kws kos duab duab puab thiab siv quav ciab yog txhaj lossis nchuav rau hauv cov kab noj hniav.

Tsob Ntoo Tsob Ntoo

Nws feem ntau tsis tsim nyog los ua qhov me me ib zaug ib zaug, yog li cov qauv siv quav ciab feem ntau txuas nrog cov quav ciab sprue. Cov wax ntawm cov qauv thiab cov sprue yog hu ua lub rooj vag, vim hais tias lawv throttle cov kev taw qhia thiab ntws ntawm cov molten alloy mus rau hauv lub void ua los ntawm cov qauv. Lub sprue pab ob lub hom phiaj

- 1. Muab qhov chaw mounting los sib sau ua ke ntau cov qauv rau hauv ib qho pwm, uas yuav tom qab ntim nrog cov hlau

- 2. Muab txoj hauv kev ntws rau cov hlau molten rau hauv qhov khoob uas tsim los ntawm cov qauv siv quav ciab.

Lub Tsev Plhaub

Cov kauj ruam tom ntej ntawm tus txheej txheem yog tsim lub plhaub ceramic nyob ib ncig ntawm tsob ntoo wax. Lub plhaub no thaum kawg yuav dhau los ua cov pwm uas hlau tau nchuav rau hauv. Txhawm rau tsim lub plhaub, tsob ntoo yog dipped rau hauv ib da dej ceramic los yog slurry. Tom qab dipping, nplua xuab zeb los yog siv rau qhov chaw ntub dej. Cov pwm raug tso cai kom qhuav, thiab cov txheej txheem rov ua dua ob peb zaug kom txog thaum txheej txheej ceramic pwm, muaj peev xwm tiv taus cov kev ntxhov siab ntawm cov hlau molten thiab alloys thaum lub sij hawm nchuav txheej txheem.

Dewax / Burnout

Ua ntej nchuav hlau rau hauv pwm, cov quav ciab raug tshem tawm los ntawm cua sov lub plhaub. Qhov no feem ntau yog ua nyob rau hauv lub chav-dewax autoclave, uas yog zoo li lub loj, muaj siab cooker. Lwm txoj kev yog siv lub qhov cub hluav taws kub, uas yaj thiab hlawv tawm ntawm cov quav ciab. Cov ciab tuaj yeem sau thiab rov siv dua los ua cov qauv siv quav ciab tom ntej. Ntau lub peev casting foundries siv ob txoj hauv kev hauv kev hais kwv txhiaj. Lub teeb hluav taws kub hnyiab tawm cov wax seem thiab kho lub plhaub, npaj tau txais cov hlau molten thiab alloys.

Hlau Pouring

Ua ntej cov hlau yog nchuav rau hauv cov pwm los yog lub plhaub, cov pwm yog preheated rau qhov kub thiab txias los tiv thaiv cov molten alloy los ntawm solidifying los yog khov tawm ua ntej tag nrho cov pwm puv. Alloy yog yaj nyob rau hauv lub khob ceramic (hu ua crucible) siv cov txheej txheem hu ua induction melting. Lub tshuab hluav taws xob ntau zaus tsim ib qho chaw sib nqus nyob ib ncig ntawm cov hlau, tsim hluav taws xob hauv cov hlau (eddy currents). Cov eddy tam sim no kub cov hlau vim cov khoom siv hluav taws xob tsis kam. Thaum cov hlau ncav cuag nws qhov ntsuas kub, nws yog nchuav rau hauv pwm, thiab cov pwm tso cai rau txias.

Plhaub Knock Off

Thaum txias, cov khoom siv plhaub raug tshem tawm ntawm cov hlau los ntawm kev siv tshuab xws li rauj, dej kub siab blasting lossis vibratory rooj. Kev tshem tawm ntawm lub plhaub kuj tseem tuaj yeem ua tiav cov tshuaj, siv cov tshuaj rhuab caustic ntawm poov tshuaj hydroxide lossis sodium hydroxide, tab sis txoj hauv kev no tau raug txiav tawm vim muaj kev txhawj xeeb ntawm ib puag ncig thiab kev noj qab haus huv.

Txiav tawm

Thaum cov khoom siv plhaub tau raug tshem tawm, lub sprue thiab lub rooj vag raug txiav tawm manually lossis los ntawm chop saw, teeb laser txiav. Cov chaw txiav yuav tsum tau grinded rau hauv qhov chaw zoo.

Tus kheej Castings

Tom qab cov khoom raug tshem tawm ntawm lub sprue, thiab cov rooj vag tshem tawm, qhov saum npoo tuaj yeem ua tiav los ntawm ntau txoj kev xws li vibratory, xov xwm xov, belting, tes sib tsoo, polishing. Kev ua tiav tuaj yeem ua tiav los ntawm tes, tab sis ntau zaus nws yog automated.Casting qhov chawtom qab ntawd raug tshuaj xyuas, cim (yog tias xav tau), ntim thiab xa tawm. Nyob ntawm daim ntawv thov, cov peev txheej casting tuaj yeem siv rau hauv lawv "net shape" lossis undergotshuabrau precision nto.

Post lub sij hawm: Jan-18-2021