Muaj electrocoating yog siv dav siv los kho qhov chaw tiv thaivhlau castingsthiab CNC machining cov khoom los ntawm corrosion nrog zoo tiav. Ntau tus neeg muas zaub nug cov lus nug txog kev kho saum npoo ntawm cov hlau castings thiabprecision machined qhov chaw. Kab lus no yuav tsom mus rau cov txheej txheem electrophoretic txheej. Vam tias nws yuav pab tau rau txhua tus neeg koom tes.

Electrocoating yog txheej txheej txheej uas cov khoom xws li pigments thiab resins raug tshem tawm hauv cov tshuaj electrophoretic yog taw qhia kom tsiv teb tsaws thiab tso rau saum npoo ntawm ib qho ntawm cov electrodes los ntawm kev siv hluav taws xob sab nraud. Lub hauv paus ntsiab lus ntawm electrophoretic txheej tau tsim nyob rau thaum xaus ntawm lub xyoo 1930s, tab sis cov cuab yeej no tau tsim thiab tau txais kev lag luam tom qab xyoo 1963. Cov txheej txheem electrophoretic yog cov txheej txheem tsim kho zoo tshaj plaws rau cov txheej txheem dej. Electrophoretic txheej muaj cov yam ntxwv ntawm cov dej solubility, non-toxicity, thiab yooj yim tswj tsis siv neeg. Vim tias nws yog qhov tsim nyog rau kev kho deg ntawm cov khoom siv hluav taws xob (hlau castings, machined qhov chaw, forgings, sheet hlau qhov chaw thiab vuam qhov chaw, thiab lwm yam), cov txheej txheem electrophoretic txheej tau sai sai tau siv dav hauv kev lag luam xws li tsheb, khoom siv hauv tsev, kho vajtse. , thiab cov khoom siv hauv tsev.

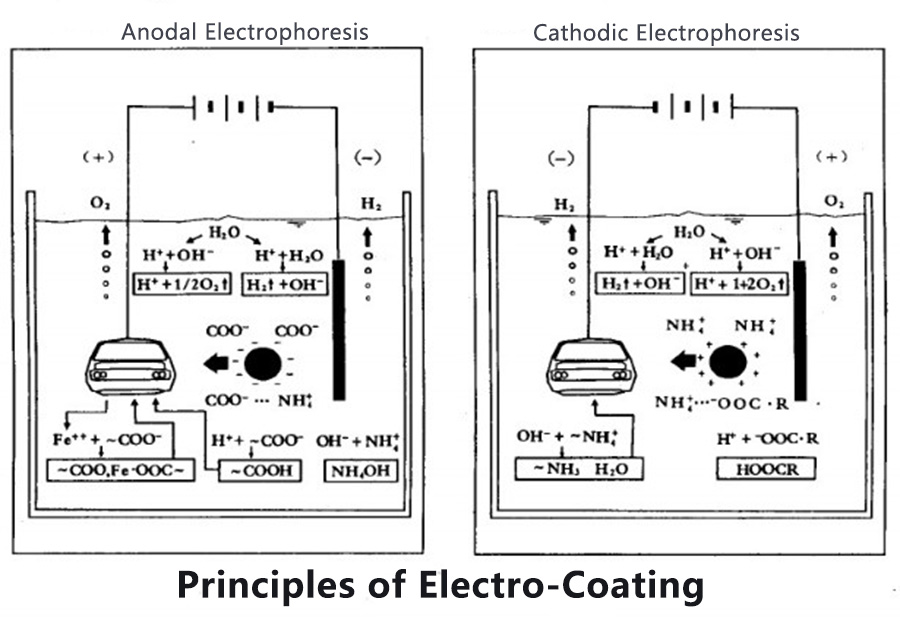

Cov ntsiab cai

Cov resin muaj nyob rau hauv cathodic electrophoretic txheej muaj cov pab pawg hauv paus, uas tsim cov ntsev tom qab acid neutralization thiab yaj hauv dej. Tom qab siv ncaj qha tam sim no, cov kua qaub radical tsis zoo ions txav mus rau lub anode, thiab cov resin ions thiab cov xim uas qhwv los ntawm lawv txav mus rau cathode nrog cov nqi zoo thiab muab tso rau hauv cathode. Qhov no yog lub hauv paus ntsiab lus ntawm electrophoretic txheej (feem ntau hu ua plating). Electrophoresis txheej yog cov tshuaj tiv thaiv electrochemical heev, tsawg kawg yog plaub qhov teebmeem ntawm electrophoresis, electrodeposition, electrolysis, thiab electroosmosis tshwm sim ib txhij.

Electrophoresis

Tom qab lub anode thiab cathode nyob rau hauv lub colloidal tov yog powered on, lub colloidal hais tsiv mus rau lub cathode (los yog anode) sab nyob rau hauv qhov kev txiav txim ntawm hluav taws xob teb, uas yog hu ua electrophoresis. Cov tshuaj nyob rau hauv cov tshuaj colloidal tsis yog nyob rau hauv lub xeev ntawm molecules thiab ions, tab sis lub solute dispersed nyob rau hauv cov kua. Cov khoom yog loj thiab yuav tsis precipitate mus rau hauv lub xeev dispersed.

Electrodeposition

Qhov tshwm sim ntawm cov nag lossis daus los ntawm cov kua yog hu ua agglomeration (agglomeration, deposition), uas feem ntau yog tsim thaum txias los yog tsom rau cov tshuaj, thiab electrophoretic txheej cia siab rau hluav taws xob. Nyob rau hauv cathodic electrophoretic txheej, zoo nqi hais aggregate ntawm lub cathode, thiab tsis zoo nqi hais (ie ions) aggregate ntawm lub anode. Thaum cov khoom zoo colloidal (cov resin thiab pigment) ncav cuag cathode (substrate) Tom qab qhov chaw saum npoo av (hloov alkaline interface txheej), electrons tau txais thiab hnov mob nrog hydroxide ions los ua dej-insoluble tshuaj, uas tso rau ntawm cathode ( pleev xim rau workpiece).

Electrolysis

Hauv kev daws teeb meem nrog ionic conductivity, anode thiab cathode txuas nrog ncaj qha tam sim no, anions raug nyiam rau lub anode, thiab cations yog attracted rau cathode, thiab cov tshuaj tiv thaiv tshwm sim. Lub anode ua cov hlau tawg thiab electrolytic oxidation los tsim cov pa oxygen, chlorine, thiab lwm yam. Lub anode yog ib qho electrode uas tuaj yeem tsim cov tshuaj tiv thaiv oxidation. Cov hlau yog precipitated ntawm cathode thiab H + yog electrolytically txo rau hydrogen.

Electroosmosis

Tom qab ob qhov kawg (cathode thiab anode) ntawm cov kev daws teeb meem nrog cov concentrations sib txawv sib cais los ntawm ib lub semipermeable membrane yog energized, qhov tshwm sim uas cov tshuaj uas tsis muaj concentration txav mus rau sab siab-concentration yog hu ua electroosmosis. Lub txheej zaj duab xis cia li tso rau ntawm qhov chaw ntawm cov khoom coated yog ib zaj duab xis semi-permeable. Nyob rau hauv qhov kev txiav txim tas mus li ntawm cov hluav taws xob, cov dej uas muaj nyob rau hauv smearing zaj duab xis dialysis tawm ntawm zaj duab xis thiab txav mus rau hauv da dej kom lub cev qhuav dej ntawm zaj duab xis. Qhov no yog electroosmosis. Electroosmosis hloov cov yeeb yaj kiab hydrophilic rau hauv cov yeeb yaj kiab hydrophobic, thiab lub cev qhuav dej ua rau cov yeeb yaj kiab txheej tuab. Cov xim ntub dej tom qab da dej nrog zoo electro-osmosis electrophoretic xim tuaj yeem kov thiab tsis nplaum. Koj tuaj yeem yaug cov kua dej da dej uas ua rau cov xim ntub dej ntub dej.

Cov yam ntxwv ntawm Electrocoating

Electrophoretic xim zaj duab xis muaj qhov zoo ntawm fullness, uniformity, flatness thiab du txheej. Lub hardness, adhesion, corrosion kuj, cuam tshuam kev ua tau zoo, thiab permeability ntawm electrophoretic xim zaj duab xis yog ho zoo dua li lwm cov txheej txheem txheej.

(1) Cov xim dej-soluble yog siv, dej siv los ua qhov nruab nrab dissolving, uas txuag tau ntau cov organic solvents, zoo heev txo cov pa phem thiab ib puag ncig muaj kev phom sij, muaj kev nyab xeeb thiab huv, thiab zam qhov phom sij zais ntawm hluav taws;

(2) Kev ua haujlwm ntawm cov xim yog siab, cov xim poob yog me me, thiab kev siv cov xim tuaj yeem ncav cuag 90% txog 95%;

(3) Cov txheej txheej zaj duab xis tuab yog sib xws, adhesion muaj zog, thiab txheej txheej zoo yog qhov zoo. Txhua qhov ntawm cov khoom ua haujlwm, xws li txheej txheej sab hauv, kev nyuaj siab, welds, thiab lwm yam, tuaj yeem tau txais cov txheej txheem zoo li qub thiab du, uas daws qhov teeb meem ntawm lwm cov txheej txheem txheej txheej rau kev ua haujlwm nyuaj. Teeb meem painting;

(4) Kev ua haujlwm ntau lawm yog siab, thiab kev tsim kho tuaj yeem paub tsis siv neeg thiab ua haujlwm tas mus li, uas txhim kho kev ua haujlwm zoo;

(5) Cov cuab yeej siv tau yooj yim, tus nqi peev yog siab, kev siv hluav taws xob loj, qhov kub thiab txias yuav tsum tau ziab thiab kho yog siab, kev tswj cov xim thiab pleev xim yog qhov nyuaj, kev tsim kho yog nruj, thiab kev kho dej khib nyiab yuav tsum tau ua. ;

(6) Tsuas yog cov xim dej-soluble tuaj yeem siv tau, thiab cov xim tsis tuaj yeem hloov pauv thaum txheej txheej txheej txheej. Kev ruaj ntseg ntawm cov xim tsis yooj yim los tswj tom qab khaws cia rau lub sijhawm ntev.

(7) Cov khoom siv electrophoretic txheej yog qhov nyuaj thiab cov ntsiab lus thev naus laus zis siab, uas tsim nyog rau kev tsim cov xim ruaj khov.

Kev txwv ntawm Electrocoating

(1) Nws tsuas yog tsim rau primer txheej ntawm conductive substrates xws li machinery qhov chaw ntawm ferrous hlau thiab non-ferrous hlau. Cov khoom uas tsis yog-conductive xws li ntoo, yas, ntaub, thiab lwm yam yuav tsis tau coated nrog txoj kev no.

(2) Cov txheej txheem electrophoresis tsis haum rau cov khoom coated uas muaj ntau yam hlau, yog tias cov yam ntxwv electrophoresis txawv.

(3) Cov txheej txheem electrophoretic tsis tuaj yeem siv rau cov khoom coated uas tsis tuaj yeem tiv taus qhov kub thiab txias.

(4) Electrophoretic txheej tsis haum rau txheej nrog kev txwv ntawm cov xim. Electrophoretic txheej ntawm cov xim sib txawv yuav tsum tau pleev xim rau hauv cov grooves sib txawv.

(5) Cov txheej txheej electrophoretic tsis pom zoo rau cov khoom me me (lub sijhawm rov ua dua tshiab ntawm da dej yog ntau tshaj 6 lub hlis), vim tias qhov rov ua dua tshiab ntawm da dej qeeb dhau, cov resin hauv da dej yog laus thiab cov ntsiab lus hnyav hloov. zoo heev. Lub da dej tsis ruaj khov.

Cov kauj ruam ntawm Electrocoating

(1) Rau electrophoretic txheej txheej ntawm cov hlau dav dav, cov txheej txheem ntws yog: ua ntej tu → degreasing → dej ntxuav → xeb tshem tawm → dej ntxuav → neutralization → dej ntxuav → phosphating → dej ntxuav → passivation → electrophoretic txheej → tank saum tu → Ultrafiltration dej ntxuav → ziab → offline.

(2) Lub substrate thiab pretreatment ntawm cov khoom coated muaj kev cuam tshuam zoo rau cov txheej txheem electrophoretic. Hlau castings feem ntau derusted los ntawm sandblasting los yog tua blasting, paj rwb xov paj yog siv los tshem tawm cov plua plav ntab saum npoo ntawm lub workpiece, thiab cov xuab zeb yog siv los tshem tawm cov seem hlau txhaj tshuaj thiab lwm yam khib nyiab ntawm qhov chaw. Cov hlau nto yog kho nrog degreasing thiab xeb tshem tawm. Thaum cov txheej txheem saum npoo siab dhau lawm, phosphating thiab passivation deg kho yuav tsum tau ua. Ferrous hlau workpieces yuav tsum tau phosphated ua ntej anodic electrophoresis, txwv tsis pub corrosion kuj ntawm cov xim zaj duab xis yuav tsis zoo. Hauv kev kho phosphating, zinc ntsev phosphating zaj duab xis feem ntau xaiv, nrog lub thickness ntawm li 1 mus rau 2 μm, thiab cov phosphate zaj duab xis yuav tsum muaj cov muaju zoo thiab zoo ib yam.

(3) Nyob rau hauv lub filtration system, cov thawj pom feem ntau yog saws, thiab lub lim yog ib tug mesh hnab qauv. Cov xim electrophoretic yog thauj mus rau lub lim los ntawm lub twj tso kua mis ntsug rau kev pom. Xav txog qhov kev hloov pauv dav dav thiab qhov zoo ntawm cov xim zaj duab xis, lub hnab lim nrog lub pore loj ntawm 50μm yog qhov zoo tshaj plaws. Nws tuaj yeem tsis tsuas yog ua tau raws li qhov yuav tsum tau ua ntawm cov xim zaj duab xis, tab sis kuj daws qhov teeb meem ntawm lub hnab lim clogging.

(4) Qhov loj ntawm lub voj voog ntawm electrophoretic txheej ncaj qha cuam tshuam rau kev ruaj ntseg ntawm da dej thiab qhov zoo ntawm cov xim zaj duab xis. Ua kom lub voj voog ntim txo cov nag lossis daus thiab npuas ntawm cov kua da dej; Txawm li cas los xij, kev laus ntawm cov kua da dej nrawm nrawm, lub zog noj nce ntxiv, thiab kev ruaj ntseg ntawm cov kua da dej ua rau tsis zoo. Nws yog qhov zoo tshaj plaws los tswj lub voj voog lub sij hawm ntawm lub tank kua rau 6-8 zaug / h, uas tsis tsuas yog lav qhov zoo ntawm cov xim zaj duab xis, tab sis kuj ua kom ruaj khov ntawm cov kua tank.

(5) Raws li lub sijhawm ntau lawm, qhov impedance ntawm anode diaphragm yuav nce thiab qhov ua haujlwm tau zoo yuav txo qis. Yog li ntawd, nyob rau hauv ntau lawm, kev khiav hauj lwm voltage ntawm lub hwj chim mov yuav tsum maj mam nce raws li qhov voltage poob los them rau qhov voltage poob ntawm lub anode diaphragm.

(6) Lub tshuab ultrafiltration tswj cov concentration ntawm impurity ions coj los ntawm lub workpiece los xyuas kom meej qhov zoo ntawm txheej. Hauv kev ua haujlwm ntawm cov kab ke no, nws yuav tsum tau muab sau tseg tias thaum lub kaw lus ua haujlwm, nws yuav tsum tau ua haujlwm tsis tu ncua thiab nws raug txwv nruj kom khiav tsis tu ncua los tiv thaiv ultrafiltration membrane kom qhuav. Cov tawv nqaij qhuav thiab cov xim ua raws li ultrafiltration membrane thiab tsis tuaj yeem ntxuav kom huv si, uas yuav cuam tshuam rau cov dej permeability thiab kev pab cuam lub neej ntawm ultrafiltration membrane. Cov dej tso tawm tus nqi ntawm lub ultrafiltration membrane qhia tau hais tias kev poob qis nrog lub sijhawm khiav. Nws yuav tsum tau ntxuav ib zaug rau 30-40 hnub ntawm kev ua haujlwm tas mus li kom ntseeg tau tias cov dej ultrafiltration yuav tsum tau siv rau ultrafiltration leaching thiab ntxuav.

(7) Cov txheej txheem electrophoretic yog tsim rau cov txheej txheem ntau lawm ntawm cov kab sib dhos. Kev rov ua dua tshiab ntawm lub da dej electrophoresis yuav tsum tsis pub dhau 3 lub hlis. Kev tswj xyuas kev tshawb fawb ntawm da dej yog qhov tseem ceeb heev. Ntau yam tsis tu ncua ntawm chav da dej tau sim, thiab chav da dej tau hloov kho thiab hloov raws li qhov ntsuas tau. Feem ntau, qhov tsis sib xws ntawm cov tshuaj da dej yog ntsuas ntawm cov zaus hauv qab no: tus nqi pH, cov ntsiab lus ntawm cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob electrophoresis, cov tshuaj ultrafiltration thiab ultrafiltration tu tov, anion (anode) polar solution, circulating lotion, thiab deionization cleaning solution ib zaug. ib hnub; Lub hauv paus piv, cov ntsiab lus organic hnyav, thiab kuaj lub tank me me ob zaug hauv ib lub lis piam.

(8) Rau kev tswj xyuas qhov zoo ntawm cov xim zaj duab xis, qhov sib xws thiab tuab ntawm cov xim pleev xim yuav tsum tau xyuas ntau zaus, thiab cov tsos yuav tsum tsis txhob muaj pinholes, sagging, txiv kab ntxwv tev, wrinkles, thiab lwm yam. Tsis tu ncua xyuas lub cev thiab tshuaj. cov ntsuas xws li adhesion thiab corrosion kuj ntawm txheej zaj duab xis. Kev tshuaj xyuas lub voj voog yog raws li cov chaw tsim khoom cov qauv tshuaj ntsuam xyuas, thiab feem ntau txhua pawg yuav tsum tau tshuaj xyuas.

Kev kho deg ua ntej Electrophoresis

Kev kho deg ntawm lub workpiece ua ntej txheej yog ib qho tseem ceeb ntawm electrophoretic txheej, feem ntau yog degreasing, xeb tshem tawm, deg txias, phosphating thiab lwm yam txheej txheem. Qhov zoo ntawm nws txoj kev kho mob tsis tsuas yog cuam tshuam rau cov tsos ntawm cov yeeb yaj kiab, txo cov kev ua haujlwm tiv thaiv corrosion, tab sis kuj ua rau kev ruaj ntseg ntawm cov xim pleev xim. Yog li ntawd, rau qhov chaw ntawm lub workpiece ua ntej pleev xim, nws yuav tsum tsis txhob muaj roj stains, xeb cov cim, tsis muaj pretreatment chemicals thiab phosphating sedimentation, thiab lwm yam, thiab phosphating zaj duab xis muaj ntom thiab uniform crystals. Hais txog ntau yam txheej txheem ua ntej kev kho mob, peb yuav tsis tham txog lawv tus kheej, tab sis tsuas yog tso ob peb lub ntsiab lus ntawm kev mloog:

1) Yog tias cov degreasing thiab xeb tsis huv, nws yuav tsis tsuas cuam tshuam rau kev tsim cov phosphating zaj duab xis, tab sis kuj cuam tshuam rau lub zog sib txuas, kev ua haujlwm zoo nkauj thiab corrosion kuj ntawm cov txheej. Cov xim zaj duab xis yog yooj yim rau shrinkage thiab pinholes.

2) Phosphating: Lub hom phiaj yog txhawm rau txhim kho qhov adhesion thiab tiv thaiv corrosion ntawm electrophoretic zaj duab xis. Nws lub luag haujlwm yog raws li nram no:

(1) Vim lub cev thiab tshuaj lom neeg, qhov adhesion ntawm cov organic txheej zaj duab xis rau lub substrate yog txhim kho.

(2) Cov phosphating zaj duab xis hloov cov hlau nto los ntawm tus neeg xyuas pib zoo mus rau tus neeg xyuas pib tsis zoo, yog li inhibiting qhov tsim ntawm micro-batteries ntawm cov hlau nto, tiv thaiv corrosion ntawm cov txheej, thiab ua kom cov corrosion kuj thiab dej tsis kam ntawm cov khoom. txheej. Tsis tas li ntawd, tsuas yog nyob rau hauv lub hauv paus ntawm kev ntxhib los mos thiab degreasing, txaus siab phosphating zaj duab xis tuaj yeem tsim rau ntawm qhov chaw huv, zoo, thiab tsis muaj roj. Los ntawm no nam, phosphating zaj duab xis nws tus kheej yog qhov feem ntau intuitive thiab txhim khu kev qha nws tus kheej-kuaj xyuas cov nyhuv ntawm cov txheej txheem pretreatment.

3) Ntxuav: Qhov zoo ntawm kev ntxuav ntawm txhua theem ntawm pretreatment yuav muaj kev cuam tshuam zoo rau tag nrho cov pretreatment thiab xim zaj duab xis zoo. Qhov kawg deionized dej ntxuav ua ntej pleev xim, xyuas kom meej tias cov dej ntws ntawm cov khoom coated tsis ntau dua 30μs / cm. Kev ntxuav tsis huv, xws li cov khoom ua haujlwm:

(1) Residual acid, phosphating tshuaj kua, flocculation ntawm resin nyob rau hauv cov kua xim, thiab deterioration ntawm stability;

(2) Cov khoom seem txawv teb chaws (roj stains, plua plav), shrinkage qhov, hais thiab lwm yam tsis xws luag nyob rau hauv cov xim zaj duab xis;

(3) Cov electrolytes seem thiab ntsev ua rau ua rau muaj kev cuam tshuam ntawm electrolysis thiab tsim cov pinholes thiab lwm yam mob.

Post lub sij hawm: Apr-17-2021