Grey cam khwb cia hlau khoom los ntawmxuab zeb molding txheej txheemthiab CNC machining.

Grey cam khwb cia hlau muaj npe tom qab grey xim ntawm qhov tawg nws cov ntaub ntawv. Grey cam khwb cia hlau yog siv rau cov tsev nyob qhov twg qhov nruj ntawm cov khoom yog qhov tseem ceeb tshaj nws lub zog tensile, xws li lub tog raj kheej combustion engine cylinder blocks, twj tso kua mis vaj tse, valve lub cev, lub thawv hluav taws xob, counterweights thiab hniav castings. Grey cam khwb cia hlau lub siab thermal conductivity thiab lub taub hau muaj peev xwm feem ntau yog siv los ua cam khwb cia hlau cookware thiab disc nres rotors.

Ib qho tshuaj lom neeg muaj pes tsawg leeg kom tau txais graphitic microstructure yog 2.5 mus rau 4.0% carbon thiab 1 mus rau 3% silicon los ntawm qhov hnyav. Graphite tuaj yeem tuav 6 mus rau 10% ntawm qhov ntim ntawm cov hlau grey. Silicon yog ib qho tseem ceeb rau kev ua grey hlau tsis zoo li cov hlau cam khwb cia dawb, vim hais tias silicon yog ib qho graphite stabilizing caij hauv cam khwb cia hlau, uas txhais tau hais tias nws pab cov alloy tsim graphite es tsis txhob hlau carbides; ntawm 3% silicon yuav luag tsis muaj cov pa roj carbon nyob rau hauv tshuaj ua ke nrog cov hlau.

Lub graphite yuav siv sij hawm nyob rau hauv cov duab ntawm ib tug peb-dimensional flake. Nyob rau hauv ob qhov ntev, raws li ib tug polished nto yuav tshwm nyob rau hauv ib tug microscope, cov graphite flakes tshwm li cov kab zoo. Cov lus qhia ntawm cov flakes ua raws li qhov muaj nyob rau ntawm qhov chaw; yog li ntawd, nws yog nkig. Lub xub ntiag ntawm graphite flakes ua rau Grey Hlau tau yooj yim machinable vim lawv nyiam tawg yooj yim hla cov graphite flakes. Grey hlau kuj muaj peev xwm damping zoo heev thiab yog li nws feem ntau yog siv los ua lub hauv paus rau lub tshuab cuab yeej mountings.

Grey Cast Iron Mechanical Properties | |||||||

| Cov khoom raws li DIN EN 1561 | Ntsuas | Chav tsev | TSW-GJL-150 | TSW-GJL-200 | TSW-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | TIAB SA 1030 | TIAB SA 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Tensile zog | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 : kuv |

| 0.1% Yield zog | rp0, 1 | MPA | 98-165 : kuv | 130-195 : kuv | 165-228 : kuv | 195-260 : kuv | 228-285 : kuv |

| Lub zog elongation | A | % | 0, 3-0, 8 | 0, 3-0, 8 | 0, 3-0, 8 | 0, 3-0, 8 | 0, 3-0, 8 |

| Compressive zog | σ dB | MPa | 600 | 7 20 | 840 ib | 960 ua | 1080 |

| 0.1% Compressive zog | d0,1 ua | MPa | 195 | 260 | 325 | 390 | 455 |

| Flexural zog | SB IB | MPa | 250 | 290 | 340 | 390 | 490 ib |

| Schuifspanning | σ aB | MPa | 170 | 230 | 290 | 345 | 400 |

| Shear Stress | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Module ntawm elasticity | E | GPa | 78–103 : kuv | 88-113 : kuv | 103-118 : kuv | 108-137 : kuv | 123-143 : kuv |

| Poisson naj npawb | v | - | 0,26 ib | 0,26 ib | 0,26 ib | 0,26 ib | 0,26 ib |

| Brinell hardness | HB | 160-190 : kuv | 180-220 : kuv | 190-230 : kuv | 200-240 Nws | 210-250 : kuv | |

| Ductility | s wb | MPa | 70 | 90 | 120 | 140 | 145 |

| Kev ntxhov siab thiab kev hloov siab | wb zd | MPa | 40 | 50 | 60 | 75 | 85 |

| Txoj Kev Ua Zog | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Qhov ntom | g/cm3 | 7,10 ib | 7,15 ib | 7,20 ib | 7,25 ib | 7,30 ib | |

Xuab zeb casting siv cov xuab zeb ntsuab (cov xuab zeb ntub) los yog cov xuab zeb qhuav los tsim cov txheej txheem molding. Cov xuab zeb ntsuab ntsuab yog cov txheej txheem qub qub uas siv hauv keeb kwm. Thaum ua cov pwm, cov qauv ua los ntawm cov ntoo lossis hlau yuav tsum tau ua kom tsim cov kab noj hniav hollow. Cov hlau molten ces hliv rau hauv kab noj hniav los tsim cov castings tom qab txias thiab solidification. Xuab zeb casting yog tsis tshua kim tshaj li lwm yam txheej txheem casting ob qho tib si rau pwm kev loj hlob thiab chav tsev casting ib feem. Cov xuab zeb casting, ib txwm txhais tau tias ntsuab xuab zeb casting (yog tias tsis muaj lus piav qhia tshwj xeeb). Txawm li cas los xij, niaj hnub no, lwm cov txheej txheem casting kuj tseem siv cov xuab zeb los ua pwm. Lawv muaj lawv tus kheej lub npe, xws liplhaub molding, furan resin coated xuab zeb casting (tsis muaj ci hom),poob ua npuas ncauj castingthiab nqus casting.

Sand Casting Peev Xwm ntawm RMC Foundry | ||

| Kev piav qhia | Moulding los ntawm phau ntawv | Moulding los ntawm Automatic Machine |

| Max loj ntawm Castings | 1,500mm × 1000mm × 500mm | 1,000 hli × 800 hli × 500 hli |

| Casting Weight Range | 0.5 kg - 1,000 kg | 0.5-500 kg |

| Muaj peev xwm txhua xyoo | 5,000 tons - 6,000 tons | 8,000-10,000 tons |

| Casting Tolerance | Raws li Kev Thov lossis Tus Qauv (ISO8062-2013 lossis GB / T 6414-1999) | |

| Cov khoom siv molding | Ntsuab Sand, Resin Coated Sand | |

| Casting Hlau & Alloys | Grey Hlau, Hlau Hlau, Cam khwb cia hlau, Stainless hlau, Al Alloys, Brass, Bronze ... thiab lwm yam. | |

Qhov zoo ntawm Sand Casting:

- ✔ Tus nqi qis dua vim nws pheej yig thiab siv tau cov khoom pwm thiab cov cuab yeej tsim khoom yooj yim.

- ✔ Ntau qhov hnyav ntawm chav tsev los ntawm 0.10 kg txog 500 kgs lossis loj dua.

- ✔ Ntau yam qauv los ntawm hom yooj yim mus rau hom complex.

- ✔ Haum rau kev tsim khoom ntawm ntau qhov ntau.

Tolerance Tias Sand Castings Tau Txais:

Cov kev kam rau ua tau muab faib ua Dimensional Casting Tolerances (DCT) thiab Geometrical Casting Tolerances (GCT). Peb lub tuam txhab xav tham nrog koj yog tias koj muaj kev thov tshwj xeeb ntawm qhov yuav tsum tau ua. Ntawm no nyob rau hauv cov nram qab no yog cov kev tolerances qib peb tuaj yeem ncav cuag los ntawm peb cov xuab zeb ntsuab, plhaub pwm casting thiab tsis muaj ci furan resin xuab zeb casting:

- ✔ DCT Qib los ntawm Green Sand Casting: CTG10 ~ CTG13

- ✔ DCT Qib los ntawm Plhaub Pwm Casting lossis Furan Resin Sand Casting: CTG8 ~ CTG12

- ✔ GCT Qib los ntawm Green Sand Casting: CTG6 ~ CTG8

- ✔ GCT Qib los ntawm Plhaub Pwm Casting lossis Furan Resin Sand Casting: CTG4 ~ CTG7

Hlau & Alloys Qib rau Sand Casting txheej txheem | |

| Hlau & Alloys | Nrov Qib |

| Grey Cam khwb cia hlau | GG10-GG40; GJL-100 ~ GJL-350; |

| Ntiv nplhaib (Nodualar) Hlau | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Hlau (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Carbon Steel | C20, C25, C30, C45 |

| Hlau alloy | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Stainless hlau | Ferritic Stainless hlau, Martensitic Stainless hlau, Austenitic Stainless hlau, nag lossis daus Hardening Stainless hlau, Duplex Stainless hlau |

| Aluminium Alloys | Txuj: ASTM A356, ASTM A413, ASTM A360 |

| Brass / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Txuj: ASTM, SAE, AISI, GOST, DIN, EN, ISO, thiab GB | |

-

Grey Casting Hlau Sand Casting Khoom

-

Grey Casting Hlau Plhaub Casting Khoom

-

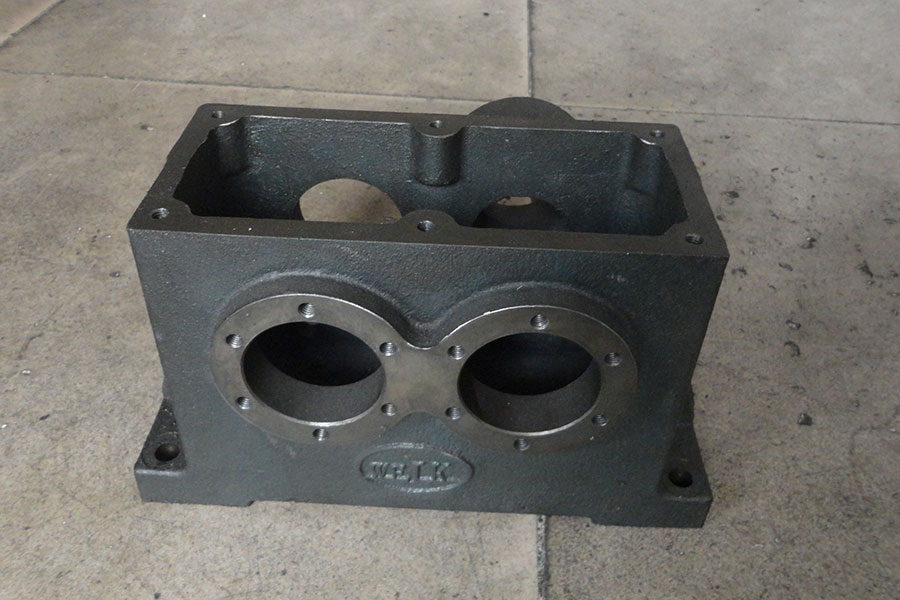

OEM Grey Cam khwb cia hlau Casting

-

Alloy Steel Resin Coated Sand Casting Crankshaft

-

Alloy Steel Sand Castings

-

Alloy Steel Truck Parts los ntawm Sand Casting thiab CNC ...

-

Carbon Steel Sand Casting Company

-

Casting Steel Sand Casting

-

Aluminium Alloy Sand Casting