Kev cai grey cam khwb cia hlau casting qhov chaw los ntawmxuab zeb castingthiabCNC precision tshuabgtxheej txheem. OEM customized engineering kev pabcuam kuj muaj.

Muaj peev xwm ntawm Sand Casting molded los ntawm tes:

• Max Loj: 1,500 mm × 1000 mm × 500 mm

• Qhov hnyav: 0.5 kg - 500 kg

• Ib xyoos twg muaj peev xwm: 5,000 tons - 6,000 tons

• Tolerances: Raws li kev thov lossis tus qauv (ISO8062-2013 lossis Suav Standard GB/T 6414-1999)

• Pwm Khoom: Ntsuab Sand Casting, Plhaub Pwm Sand Casting.

Muaj peev xwm ntawm Sand Casting los ntawm Tsis Siv Neeg Moulding Machine:

• Max Loj: 1,000 mm × 800 mm × 500 mm

• Qhov hnyav: 0.5 kg - 500 kg

• Ib xyoos twg muaj peev xwm: 8,000 tons - 10,000 tons

• Tolerances: Raws li thov los yog raws li tus qauv (ISO8062-2013 los yog Suav Standard GB/T 6414-1999)

• Pwm Khoom: Ntsuab Sand Casting, Resin Coated Sand Plhaub Molding Casting.

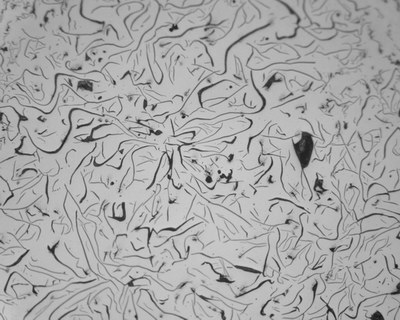

Covxuab zeb mould casting qhov chawntawm RMC yog nruab nrog lub chaw kuaj metallurgical ua tiav los txiav txim siab cov tshuaj lom neeg thiab cov yam ntxwv ntawm txhua qhov yaj thiab txheeb xyuas cov xwm txheej metallurgic ntawm cov hlau molten ua ntej nchuav. Microsections raug tshuaj xyuas nyob rau hauv lub microscope kom tau txais cov ntaub ntawv zaum kawg. Yog tias ua tau lossis xav tau, peb tuaj yeem muab 3.1 Daim Ntawv Pov Thawj rau txhua qhov khoom xa tuaj ntawm cov neeg siv khoom xav tau.

Sand casting khoomtuaj yeem ua haujlwm hauvntau kev lag luamxws li Drums, Iav, Iav tsev, Mining Machinery, Mounting Thaiv, Hydraulic Pressure Twj, Bearing Seat, Txhawb Nplhaib, Idler Log, Clamp, Mounting Bracket, Log Hub, Wedge Socket, Track Pad Rau Mining Equipment, Hydraulic Qws Yoke. .lwm.

| Mechanical Properties ntawm Grey Cam khwb cia hlau | |||||||

| Cov khoom raws li DIN EN 1561 | Ntsuas | Chav tsev | TSW-GJL-150 | TSW-GJL-200 | TSW-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | TIAB SA 1030 | TIAB SA 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Tensile zog | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 : kuv |

| 0.1% Yield zog | rp0, 1 | MPA | 98-165 : kuv | 130-195 : kuv | 165-228 : kuv | 195-260 : kuv | 228-285 : kuv |

| Lub zog elongation | A | % | 0, 3-0, 8 | 0, 3-0, 8 | 0, 3-0, 8 | 0, 3-0, 8 | 0, 3-0, 8 |

| Compressive zog | σ dB | MPa | 600 | 7 20 | 840 ib | 960 ua | 1080 |

| 0.1% Compressive zog | d0,1 ua | MPa | 195 | 260 | 325 | 390 | 455 |

| Flexural zog | SB IB | MPa | 250 | 290 | 340 | 390 | 490 ib |

| Schuifspanning | σ aB | MPa | 170 | 230 | 290 | 345 | 400 |

| Shear Stress | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Module ntawm elasticity | E | GPa | 78–103 : kuv | 88-113 : kuv | 103-118 : kuv | 108-137 : kuv | 123-143 : kuv |

| Poisson naj npawb | v | - | 0,26 ib | 0,26 ib | 0,26 ib | 0,26 ib | 0,26 ib |

| Brinell hardness | HB | 160-190 : kuv | 180-220 : kuv | 190-230 : kuv | 200-240 Nws | 210-250 : kuv | |

| Ductility | s wb | MPa | 70 | 90 | 120 | 140 | 145 |

| Kev ntxhov siab thiab kev hloov siab | wb zd | MPa | 40 | 50 | 60 | 75 | 85 |

| Txoj Kev Ua Zog | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Qhov ntom | g/cm3 | 7,10 ib | 7,15 ib | 7,20 ib | 7,25 ib | 7,30 ib | |

Cam khwb cia hlau yog cov hlau-carbon cam khwb cia hlau nrog lwm cov khoom uas yog tsim los ntawm remelting npua hlau, seem, thiab lwm yam ntxiv. Rau kev sib txawv ntawm cov hlau thiab cam khwb cia hlau, cam khwb cia hlau yog txhais raws li cam khwb cia hlau nrog cov ntsiab lus carbon (min 2.03%) uas ua kom cov solidification ntawm theem kawg nrog kev hloov pauv eutectic. Raws li kev txheeb xyuas tshuaj, cam khwb cia hlau tuaj yeem yog non-alloyed lossis alloyed. Qhov ntau ntawm cov hlau alloyed yog dav dua, thiab lawv muaj ntau dua ntawm cov khoom sib xws, xws li silicon thiab manganese, lossis tshwj xeeb ntxiv, xws li npib tsib xee, chromium, aluminium, molybdenum, tungsten, tooj liab, vana-dium, titanium, ntxiv rau. lwm tus. Feem ntau hais lus, cam khwb cia hlau tuaj yeem muab faib ua grey hlau, ducitle hlau (nodular hlau), dawb cam khwb cia hlau, compacted graphite hlau thiab malleable cam khwb cia hlau.