Kev cai nrumduplex stainless hlau peev casting khoomlos ntawm Tuam Tshoj casting foundry nrog machining, kev kho cua sov, thiab kev kho deg.

RMC kevprecision cam khwb cia steel qhov chawuas tsis tu ncua ua tau raws li lossis tshaj qhov xav tau ntawm cov neeg siv khoom. Poob ciab peev casting tso cai rau peb los tsim cov hlau me me li kaum ntawm grams thiab loj li kaum kilograms, nyob rau hauv ib tug ntau yam ntawm ferrous thiab non-ferrous alloys thiab nrog exceptional dimensional raug.

Cov txheej txheem wax ploj ploj ua rau ze-net-zoo li precision hlau qhov uas feem ntau yuav tsum tau me me los yog tsis muaj ntxiv machining. Qhov ua tiav tiav kuj zoo dua li qhov ua tiav los ntawm lwm cov txheej txheem. Lub zog thiab durability ntawm cov casting qhov chaw ua rau lawv tus kheej zoo tagnrho rau kev hnav-tiv taus daim ntaub ntawv xav tau ntau lab lub voj voog.

Duplex Stainless Steel (DSS) yog hais txog stainless hlau nrog ferrite thiab austenite txhua tus accounting txog li 50%. Feem ntau, cov ntsiab lus ntawm cov theem tsawg yuav tsum muaj tsawg kawg yog 30%. Hauv cov ntsiab lus C tsawg, cov ntsiab lus Cr yog 18% txog 28%, thiab Ni cov ntsiab lus yog 3% txog 10%. Qee qhov duplex stainless hlau kuj muaj cov ntsiab lus alloying xws li Mo, Cu, Nb, Ti, thiab N.

Muaj qib ntawm duplex stainless hlau ntawm RMC Casting Foundry: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890 3A 5A, A4 A9 A9 1B, A 995 4A, A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

DSS muaj cov yam ntxwv ntawm austenitic thiab ferritic stainless hlau. Piv nrog rau ferrite, nws muaj ntau dua plasticity thiab ductility, tsis muaj chav kub brittleness, thiab txhim kho intergranular corrosion kuj thiab vuam kev ua tau zoo, thaum tseem tuav brittleness, siab thermal conductivity, thiab superplasticity li ferrite stainless hlau. Piv nrog austenitic stainless hlau, DSS muaj lub zog siab thiab txhim kho kev ua haujlwm zoo rau intergranular corrosion thiab chloride stress corrosion. Duplex stainless hlau muaj zoo heev pitting corrosion kuj thiab kuj yog ib tug nickel-txuag stainless hlau.

| Qib sib npaug ntawm Stainless Hlau | |||||||

| Pawg | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic thiab Ferritic Stainless Hlau | 420c ua | 1, 4034 ib | X43Cr16 | ||||

| 440 IB/1 | 1, 4112 ib | X90 Cr Mo V18 | |||||

| - | 1.208 3 | Txc42 13 | - | 2314 ib | F.5263 | - | |

| 403 | 1.4000 Nws | X6Cr13 | 403 Ib. 17 | 2301 ib | F.3110 | X6Cr13 | |

| (410S) | 1.4001 Nws | Txc7 14 | (403 S17) | 2301 ib | F.3110 | X6Cr13 | |

| 405 | 1.400 2 | X6 CrAl 13 | 405 Ib. 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 Nws | X12 CrS 13 | 416 AWV 21 | 2380 ua | F.3411 | X12CrS13 | |

| 410 | 1.400 6 | X 10 Cr 13 | 410 S21 | 2302 ib | F.3401 | X12Cr13 | |

| 430 | 1.4016 | Txc6 17 | 430, HWV 17 | 23 20 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 Ib. 37 | 2303 ib | F.3402 | X20Cr13 | |

| 420f ua | 1.4028 ib | Tx30 13 | 420 Ib. 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 Ib. 45 | (2304) | F.3404 | - | |

| 431 ib | 1.4057 Nws | X20 CrNi 17 2 | 431 s29 ib | 2321 ib | F.3427 | X16CrNi16 | |

| 430f ua | 1.4104 ib | X12 CrMoS 17 | - | ib 2383 | F.3117 | X10CrS17 | |

| 434 ib | 1.411 3 | X6 CrMo 17 | 434 S 17 | 23 25 | - | X8CrMo17 | |

| 4 30 Ti | 1.4510 Nws | Tx6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 ib | 1.4512 ib | Tx5 CrTi 12 | 409 Ib. 17 | - | - | X6CrTi12 | |

| Austenitic Stainless hlau | 304 | 1.4301 ib | Tx5 CrNi 18 9 | 304 S 15 | 2332 ib | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 ib | Tx5 CrNi 18 12 | 305 Ib. 19 | - | - | Tx8CrNi19 10 | |

| 303 | 1.4305 Nws | X12 CrNiS 18 8 | 303 Ib. 21 | 2346 ib | F.3508 | X10CrNiS 18 09 | |

| 304l ua | 1.4306 ib | X2 CrNiS 18 9 | 304 S 12 | 2352 ib | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 Nws | X12 CrNi 17 7 | - | 2331 ib | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 Nws | Tx5 CrNi 18 9 | 304 Ib. 31 | 2332 ib | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 Nws | Tx5 CrNi 18 9 | 304 Ib. 31 | ib 2333 | F.3551 | X5CrNi18 10 | |

| 304 LN ib | 1.4311 ib | X2 CrNiN 18 10 | 304s62 ib | 2371 ib | - | - | |

| 316 | 1.4401 Nws | X5 CrNiMo 18 10 | 316 Ib. 16 | 2347 ib | F.3543 | X5CrNiMo17 12 | |

| 316l ua | 1.4404 ib | - | 316 S 12/13/14/22/24/24/12/13/12/13/14/22/24/ 12/13/14/22/24 | 2348 ib | X2CrNiMo17 12 | ||

| 316 LN ib | 1.4429 ib | X2 CrNiMoN 18 13 | - | 2375 ib | - | - | |

| 316l ua | 1.4435 ib | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24/24/12/13/12/13/14/22/24/ 12/13/14/22/24 | 2353 ua | - | X2CrNiMo17 12 | |

| 316 | 1.4436 ib | - | 316 Ib. 33 | 2343 ib | - | X8CrNiMo 17 13 | |

| 317l ua | 1.4438 ib | X2 CrNiMo 18 16 | 317 Ib. 12 | 2367 ib | - | X2CrNiMo18 16 | |

| 329 | 1.4460 Nws | X3 CrNiMoN 27 5 2 | - | 2324 ib | F.3309 | - | |

| 321 | 1.4541 ib | X10 CrNiTi 18 9 | 321 Ib. 12 | 2337 ib | F.3553 | X6CrNiTi18 11 | |

| 347 ib | 1.4550 Nws | X10 CrNiNb 18 9 | 347 Ib. 17 | ib 2338 | F.3552 | X6CrNiNb18 11 | |

| 316 Ti | 1.4571 ib | X10 CrNiMoTi 18 10 | 320 Ib. 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 ib | X15 CrNiSi 20 12 | 309 Ib. 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 ib | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Stainless Hlau | S32750 | 1.4410 Nws | X 2 CrNiMoN 25 7 4 | - | 2328 ib | - | - |

| S31500 Nws | 1.4417 ib | X 2 CrNiMoSi 19 5 | - | 2376 ib | - | - | |

| S31803 | 1.4462 ib | X 2 CrNiMoN 22 5 3 | - | 2377 ib | - | - | |

| wb 32760 | 1.4501 Nws | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 ib | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

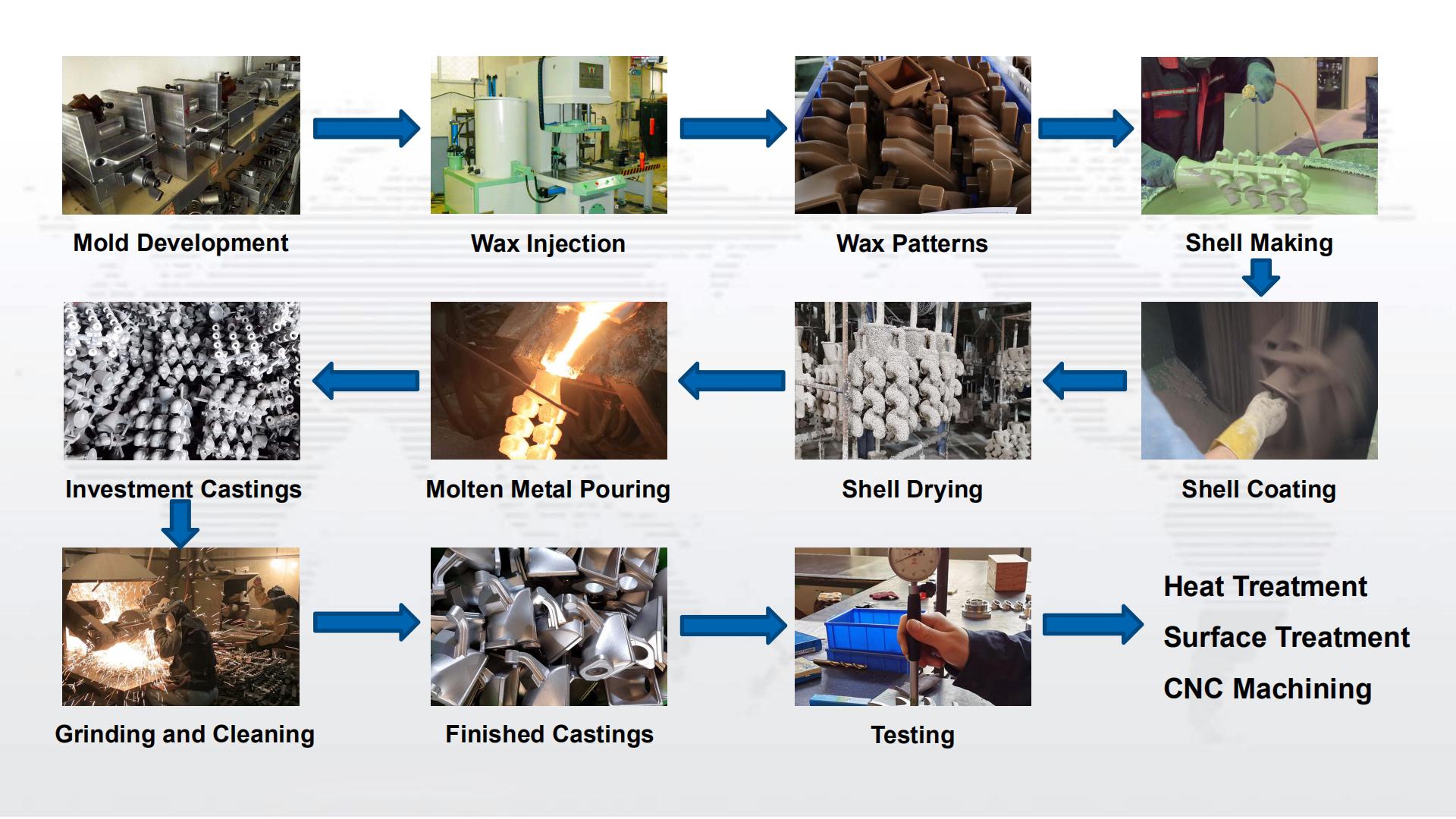

▶ Ferrous Metals thiab Non-ferrous Hlau rauKev nqis peev Casting, Poob Wax Casting Txheej Txheem:

• Grey Hlau: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10-GG40.

• Cov Hlau Hlau lossis Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

• Hlau Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo... thiab lwm yam ntawm kev thov.

• Stainless hlau: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 thiab lwm yam stainless hlau qib.

• Brass, Liab Copper, Bronze los yog lwm yam tooj liab-raws li alloy hlau: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Lwm cov ntaub ntawv raws li koj cov kev cai tshwj xeeb lossis raws li ASTM, SAE, AISI, ACI, DIN, EN, ISO, thiab GB qauv

▶ Muaj peev xwm ntawmKev nqis peev Casting Foundry

• Max Loj: 1,000 mm × 800 mm × 500 mm

• Qhov hnyav: 0.5 kg - 100 kg

• Ib xyoos twg muaj peev xwm: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Dej iav thiab lawv cov khoom sib tov.

| Kev pabcuam | Kev piav qhia |

| Kev Kho Ntog Kev Pabcuam | Hmoov Txheej, Anodization, Electrophotesis, Chrome Plating, Painting, Sand blasting, Nickel Plating, Zinc Plating, Blacking, Polishing, Bluing, Geormet, Zintek, thiab lwm yam. |

| CNC Precision Machining Services | Lathing, Milling, Tig, Honing, Drilling, Boring, Tapping, Hlau Electrode Txiav, Sib Tsoo ... thiab lwm yam. |

| Kev tshuaj xyuas thiab kev tswj xyuas zoo | Spectrum Analyzer, CMM, Hardness Tester, Tensile Strength Tester, Yild Strentgh Testor, Sealing Pressure Tester, Carbon Sulfur Analyzer, Metallurgical Microscopy, Press Force Tester ... thiab lwm yam. |