2205 duplex stainless hlau yog duplex stainless hlau muaj li ntawm 21% chromium, 2.5% molybdenum thiab 4.5% nickel-nitrogen alloy. Cov ferrite thiab austenite tsim txhua tus account rau kwv yees li 50%. Nws muaj lub zog siab, zoo cuam tshuam toughness thiab zoo tag nrho thiab hauv zos kev ntxhov siab corrosion kuj. Lub zog tawm los ntawm 2205 duplex stainless hlau yog ob zaug ntawm austenitic stainless hlau. Cov yam ntxwv no ua rau cov neeg tsim qauv txo qhov hnyav thaum tsim cov khoom lag luam, ua rau cov hlau no siv nyiaj ntau dua li 316 thiab 317L. Cov hlau no tshwj xeeb tshaj yog haum rau qhov kub ntawm -50 ° F / + 600 ° F. Rau cov ntawv thov dhau qhov ntsuas kub no, cov hlau no kuj tuaj yeem txiav txim siab, tab sis muaj qee qhov kev txwv, tshwj xeeb tshaj yog thaum siv rau cov qauv welded.

Piv nrog 316L thiab 317L austenitic stainless hlau, 2205 duplex stainless hlau muaj kev ua tau zoo tshaj plaws hauv kev tiv thaiv pitting corrosion thiab crevice corrosion. Nws muaj siab corrosion kuj. Piv nrog rau austenitic, nws cov coefficient ntawm thermal expansion yog qis dua thiab cov thermal conductivity siab dua. Piv nrog austenitic stainless hlau, duplex stainless hlau 2205 alloy muaj ob zaug nws compressive zog. Piv nrog 316L thiab 317L, tus tsim qauv tuaj yeem txo nws qhov hnyav. Alloy 2205 yog tshwj xeeb tshaj yog haum rau qhov kub ntawm -50 ° F / + 600 ° F. Raws li kev txwv nruj (tshwj xeeb tshaj yog rau cov qauv welded), nws kuj tuaj yeem siv rau qhov kub thiab txias.

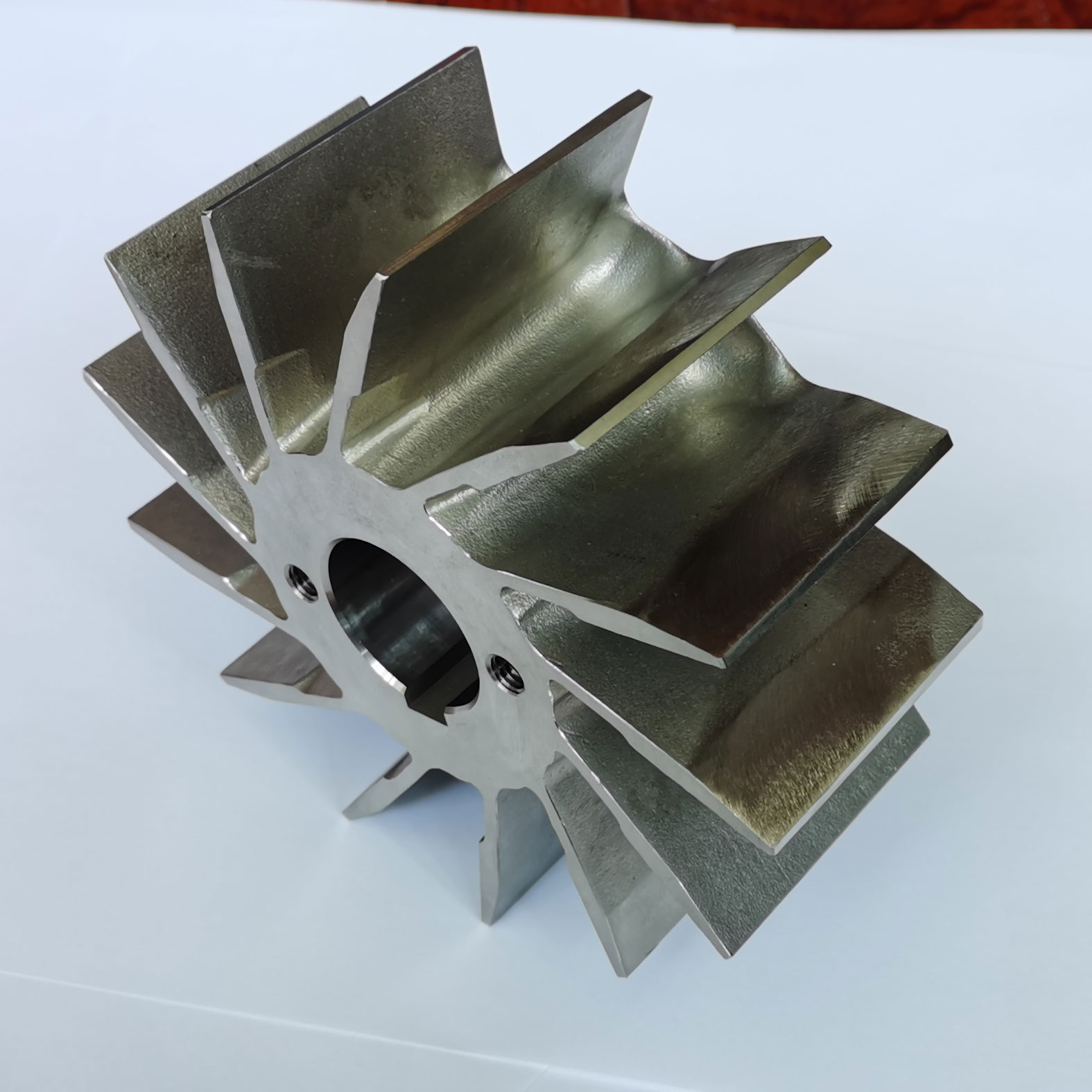

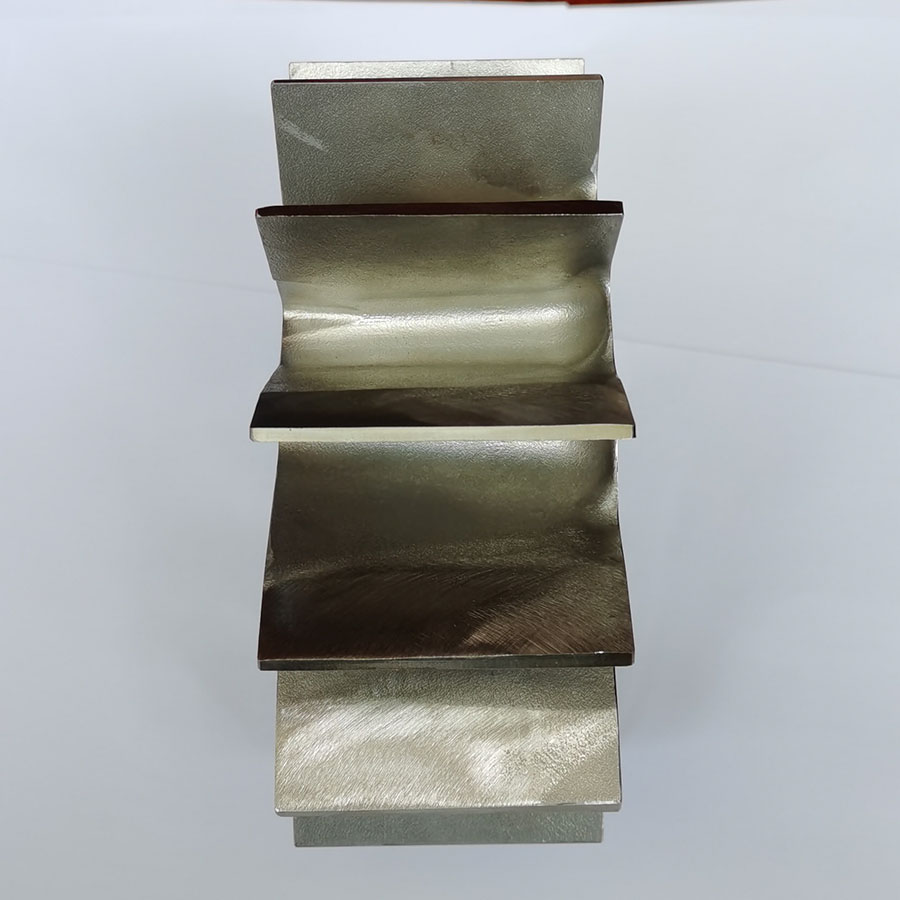

Duplex stainless hlau castingtxhais tau hais tias cov castings ua los ntawm duplex stainless hlau. Duplex Stainless Steel (DSS) yog hais txog stainless hlau nrog ferrite thiab austenite txhua tus accounting txog li 50%. Feem ntau, cov ntsiab lus ntawm cov theem tsawg yuav tsum muaj tsawg kawg yog 30%. Hauv cov ntsiab lus C tsawg, cov ntsiab lus Cr yog 18% txog 28%, thiab Ni cov ntsiab lus yog 3% txog 10%. Qee qhov duplex stainless hlau kuj muaj cov ntsiab lus alloying xws li Mo, Cu, Nb, Ti, thiab N.

DSS muaj cov yam ntxwv ntawm austenitic thiab ferritic stainless hlau. Piv nrog rau ferrite, nws muaj ntau dua plasticity thiab ductility, tsis muaj chav kub brittleness, thiab txhim kho intergranular corrosion kuj thiab vuam kev ua tau zoo, thaum tseem tuav brittleness, siab thermal conductivity, thiab superplasticity li ferrite stainless hlau. Piv nrog austenitic stainless hlau, DSS muaj lub zog siab thiab txhim kho kev ua haujlwm zoo rau intergranular corrosion thiab chloride stress corrosion. Duplex stainless hlau muaj zoo heev pitting corrosion kuj thiab kuj yog ib tug nickel-txuag stainless hlau.

Hauv casting ntau lawm, feem ntau ntawm stainless hlau castings yog ua tiav los ntawmpeev casting. Qhov saum npoo ntawm stainless hlau castings tsim los ntawm peev casting yog smoother thiab qhov tseeb qhov tseeb yog yooj yim dua los tswj. Tau kawg, tus nqi ntawmpeev casting stainless hlau qhov chawyog qhov siab dua piv rau lwm cov txheej txheem thiab cov khoom siv.

▶ Muaj peev xwm ntawmKev nqis peev Casting Foundry

• Max Loj: 1,000 mm × 800 mm × 500 mm

• Qhov hnyav: 0.5 kg - 100 kg

• Ib xyoos twg muaj peev xwm: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Dej iav thiab lawv cov khoom sib tov.

• Tolerances: Thaum Thov.

▶ Cov txheej txheem tseem ceeb ntawm kev nqis peev Casting

• Tsim ib tug qauv siv quav ciab los yog replica

• Sprue tus qauv siv quav ciab

• nqis peev tus qauv siv quav ciab

• Tshem tawm cov qauv siv quav ciab los ntawm kev hlawv nws (hauv qhov cub lossis hauv dej kub) los tsim cov pwm.

• Force molten hlau ncuav rau hauv pwm

• Txias thiab Solidification

• Tshem tawm sprue ntawm cov castings

• Ua kom tiav thiab polishing tiav cov peev txheej castings