OEM kev caiduplex stainless hlau poob ciab castingnrog kev kho cua sov, kev kho deg, CNC machining thiab kuaj cov kev pabcuam los ntawm ib tus neeg muag khoom hauv Suav teb

RMC Foundry muaj peev xwm ua tau raws li cov khoom siv tshwj xeeb raws li ASTM, SAE, AISI, ACI, DIN, EN, ISO, GOST thiab GB qauv. Peb muaj ntau tshaj 100 qhov sib txawv ferrous thiab non-ferrous alloys uas peb nrum qhov chaw siv cov qauv tsim qauv. Peb dimensionally thiab geometrically complexpeev castingsyog tsim los rau net zoo, txo qhov xav tau rau theem nrab machining.

Duplex Stainless Steel (DSS) yog hais txog stainless hlau nrog ferrite thiab austenite txhua tus accounting txog li 50%. Feem ntau, cov ntsiab lus ntawm cov theem tsawg yuav tsum muaj tsawg kawg yog 30%. Hauv cov ntsiab lus C tsawg, cov ntsiab lus Cr yog 18% txog 28%, thiab Ni cov ntsiab lus yog 3% txog 10%. Qee qhov duplex stainless hlau kuj muaj cov ntsiab lus alloying xws li Mo, Cu, Nb, Ti, thiab N.

DSS muaj cov yam ntxwv ntawm austenitic thiab ferritic stainless hlau. Piv nrog rau ferrite, nws muaj ntau dua plasticity thiab ductility, tsis muaj chav kub brittleness, thiab txhim kho intergranular corrosion kuj thiab vuam kev ua tau zoo, thaum tseem tuav brittleness, siab thermal conductivity, thiab superplasticity li ferrite stainless hlau.

Piv nrog austenitic stainless hlau, DSS muaj lub zog siab thiab txhim kho kev ua haujlwm zoo rau intergranular corrosion thiab chloride stress corrosion. Duplex stainless hlau muaj zoo heev pitting corrosion kuj thiab kuj yog ib tug nickel-txuag stainless hlau.

Peb cov khoom siv sab saum toj-ntawm-tus-kab thiab cov txheej txheem automation tswj tso cai rau kev ua kom zoo ib yam thiab rov ua kom ntev li ze li ± 0.1 hli. Peb cov castings kuj tuaj yeem tsim nyob rau hauv ntau qhov loj-lawv yuav me me li 10 hli ntev x 10 hli dav x 10 hli siab thiab hnyav li 0.01 kg, lossis ntau npaum li 1000 hli ntev thiab hnyav npaum li cas. 100 kg.

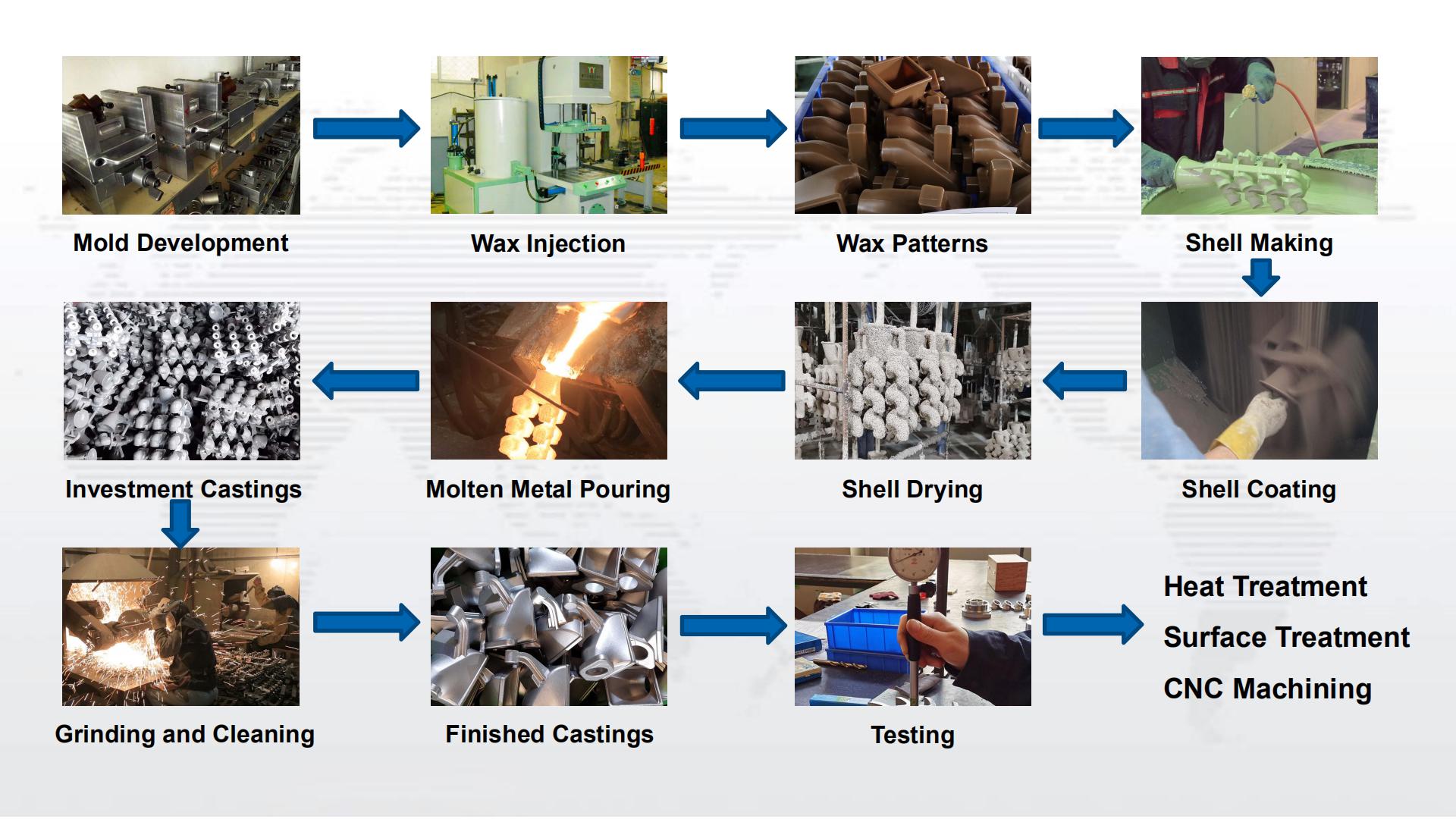

Ntawm RMC Foundry, peb txaus siab rau peb tus kheej hauv kev muab peb cov neeg siv khoom zoo tshaj plaws kev pabcuam txij thaum pib mus txog qhov kawg. Peb cov kev pabcuam suav nrog:

- - Cov cuab yeej siv hauv tsev tsim thiab tsim muaj peev xwm.

- - Kev tsim qauv qauv.

- -Txoj kev tshawb fawb thiab kev txhim kho.

- - Manufacturing yooj.

- - Kev tsim nyog thiab kev xeem.

- - Kev kho cua sov

- - Kev kho deg

- - Outsourcing Manufacturing Peev Xwm