Corrosion-resistant cam khwb cia hlau, tseem hu ua cam khwb cia stainless hlau, hais txog alloy cam khwb cia hlau uas muaj zog tiv thaiv corrosion nyob rau hauv ntau yam corrosive media los yog ib puag ncig uas corrosion thiab mechanical yam coexist.

| Ceev Saib rau Austenitic Stainless Hlau | |

| Lub ntsiab Chemical Composition | Cr, Ni, C, Mo, Cu, Si, Nb, Ti |

| Kev ua tau zoo | Non-magnetic, siab toughness, siab plasticity, tsis muaj zog |

| Txhais | Stainless hlau nrog austenitic qauv ntawm chav tsev kub |

| Cov Qib Neeg Sawv Cev | 304, 316, 1.4310, 1.4301, 1.4408 |

| Machineability | Ncaj ncees |

| Weldability | Feem ntau zoo heev |

| Kev siv yam | Khoom noj khoom haus tshuab, Hardwares, tshuaj ua hauj lwm ... thiab lwm yam |

Stainless hlau muaj qhov tsawg kawg nkaus chromium cov ntsiab lus ntawm 10.5%, ua rau nws tiv taus ntau dua rau corrosive kua ib puag ncig thiab rau oxidation. Nws yog corrosion kuj heev resistant thiab hnav resistant, muab zoo heev machinability, thiab yog paub zoo rau nws zoo nkauj tsos. Stainless hlau peev castings yog "corrosion-resistant" thaum siv nyob rau hauv cov kua ib puag ncig thiab vapors hauv qab 1200 ° F (650 ° C) thiab "heat-resistant" thaum siv saum toj no kub.

Austenitic stainless hlauhais txog stainless hlau nrog cov qauv austenitic ntawm chav tsev kub. Austenitic stainless hlau yog ib qho ntawm tsib chav kawm ntawm stainless hlau los ntawm crystalline qauv (nrog rau ferritic, martensitic, duplex thiab nag lossis daus hardened). Hauv qee qhov chaw, austentite stainless hlau tseem hu ua 300 series stainless hlau. Thaum cov hlau muaj txog 18% Cr, 8% -25% Ni, thiab txog 0.1% C, nws muaj cov qauv austenite ruaj khov. Austenitic chromium-nickel stainless hlau suav nrog lub npe nrov 18Cr-8Ni steel thiab siab Cr-Ni series steel tsim los ntawm kev ntxiv Cr thiab Ni cov ntsiab lus thiab ntxiv Mo, Cu, Si, Nb, Ti thiab lwm yam ntawm lub hauv paus no. Austenitic stainless hlau yog tsis-sib nqus thiab muaj siab toughness thiab yas, tab sis nws lub zog yog tsawg, thiab nws yog tsis yooj yim sua kom ntxiv dag zog rau nws los ntawm theem transformation. Nws tsuas tuaj yeem ntxiv dag zog los ntawm kev ua haujlwm txias. Yog hais tias cov khoom xws li S, Ca, Se, Te ntxiv, nws muaj cov khoom zoo ntawm machinability.

Austenitic stainless hlau kuj tuaj yeem tsim cov castings. Txhawm rau txhim kho cov dej ntws ntawm cov hlau molten thiab txhim kho kev ua tau zoo, cov alloy muaj pes tsawg leeg ntawm cov cam khwb cia hlau yuav tsum tau hloov kho los ntawm kev ua kom cov ntsiab lus silicon, ua kom muaj ntau yam ntawm chromium thiab npib tsib xee cov ntsiab lus, thiab ua rau lub siab txwv ntawm impurity element sulfur.

Austenitic stainless hlau yuav tsum yog cov khoom siv-kev daws teeb meem ua ntej siv, txhawm rau ua kom cov khoom siv ntau tshaj plaws ntawm ntau yam precipitates xws li carbides hauv cov hlau rau hauv austenite matrix, thaum tseem ua kom homogenizing cov qauv thiab tshem tawm kev ntxhov siab, thiaj li ua kom zoo corrosion kuj thiab mechanical zog. Txoj kev kho kom raug yog dej txias tom qab cua sov ntawm 1050 ~ 1150 ℃ (qhov nyias nyias tuaj yeem ua cua txias). Kev kho qhov kub thiab txias yog nyob ntawm qib ntawm alloying ntawm cov hlau: Molybdenum-dawb lossis qis-molybdenum steel qib yuav tsum qis dua (≤1100 ℃), thiab siab dua alloyed qib xws li 00Cr20Ni18Mo-6CuN, 00Cr25Ni22Mo2N, thiab lwm yam yuav tsum siab dua ( 1080 ~ 1150 ℃).

Austenitic 304 stainless hlau hlau phaj, uas tau hais tias coj muaj zog tiv thaiv xeb thiab corrosion kuj, thiab muaj cov yas zoo heev thiab tawv, uas yooj yim rau stamping thiab sib sau. Nrog ib tug ceev ntawm 7.93 g / cm3, 304 stainless hlau yog ib tug ntau heev stainless hlau, kuj hu ua 18/8 stainless hlau nyob rau hauv kev lag luam. Nws cov khoom siv hlau tiv taus qhov kub thiab txias thiab muaj kev ua haujlwm zoo, yog li lawv tau siv dav hauv kev lag luam thiab rooj tog kho kom zoo nkauj industries thiab khoom noj khoom haus thiab kev kho mob kev lag luam.

Qib sib npaug ntawm Stainless Hlau | |||||||

| Pawg | AISI | W-stoff | DIN | BS | SS | UNE / IHA | UNI |

| Martensitic thiab Ferritic Stainless Hlau | 420c ua | 1.4034 | X43Cr16 | ||||

| 440 IB/1 | 1.4112 ib | X90 Cr Mo V18 | |||||

| - | 1.208 3 | Txc42 13 | - | 2314 ib | F.5263 | - | |

| 403 | 1.4000 Nws | X6Cr13 | 403 Ib. 17 | 2301 ib | F.3110 | X6Cr13 | |

| (410S) | 1.4001 Nws | Txc7 14 | (403 S17) | 2301 ib | F.3110 | X6Cr13 | |

| 405 | 1.400 2 | X6 CrAl 13 | 405 Ib. 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 Nws | X12 CrS 13 | 416 AWV 21 | 2380 ua | F.3411 | X12CrS13 | |

| 410 | 1.400 6 | X 10 Cr 13 | 410 S21 | 2302 ib | F.3401 | X12Cr13 | |

| 430 | 1.4016 | Txc6 17 | 430, HWV 17 | 23 20 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 Ib. 37 | 2303 ib | F.3402 | X20Cr13 | |

| 420f ua | 1.4028 ib | Tx30 13 | 420 Ib. 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 Ib. 45 | (2304) | F.3404 | - | |

| 431 ib | 1.4057 Nws | X20 CrNi 17 2 | 431 s29 ib | 2321 ib | F.3427 | X16CrNi16 | |

| 430f ua | 1.4104 ib | X12 CrMoS 17 | - | ib 2383 | F.3117 | X10CrS17 | |

| 434 ib | 1.411 3 | X6 CrMo 17 | 434 S 17 | 23 25 | - | X8CrMo17 | |

| 4 30 Ti | 1.4510 Nws | Tx6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 ib | 1.4512 ib | Tx5 CrTi 12 | 409 Ib. 17 | - | - | X6CrTi12 | |

| Austenitic Stainless hlau | 304 | 1.4301 ib | Tx5 CrNi 18 9 | 304 S 15 | 2332 ib | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 ib | Tx5 CrNi 18 12 | 305 Ib. 19 | - | - | Tx8CrNi19 10 | |

| 303 | 1.4305 Nws | X12 CrNiS 18 8 | 303 Ib. 21 | 2346 ib | F.3508 | X10CrNiS 18 09 | |

| 304l ua | 1.4306 ib | X2 CrNiS 18 9 | 304 S 12 | 2352 ib | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 Nws | X12 CrNi 17 7 | - | 2331 ib | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 Nws | Tx5 CrNi 18 9 | 304 Ib. 31 | 2332 ib | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 Nws | Tx5 CrNi 18 9 | 304 Ib. 31 | ib 2333 | F.3551 | X5CrNi18 10 | |

| 304 LN ib | 1.4311 ib | X2 CrNiN 18 10 | 304s62 ib | 2371 ib | - | - | |

| 316 | 1.4401 Nws | X5 CrNiMo 18 10 | 316 Ib. 16 | 2347 ib | F.3543 | X5CrNiMo17 12 | |

| 316l ua | 1.4404 ib | - | 316 S 12/13/14/22/24/24/12/13/12/13/14/22/24/ 12/13/14/22/24 | 2348 ib | X2CrNiMo17 12 | ||

| 316 LN ib | 1.4429 ib | X2 CrNiMoN 18 13 | - | 2375 ib | - | - | |

| 316l ua | 1.4435 ib | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24/24/12/13/12/13/14/22/24/ 12/13/14/22/24 | 2353 ua | - | X2CrNiMo17 12 | |

| 316 | 1.4436 ib | - | 316 Ib. 33 | 2343 ib | - | X8CrNiMo 17 13 | |

| 317l ua | 1.4438 ib | X2 CrNiMo 18 16 | 317 Ib. 12 | 2367 ib | - | X2CrNiMo18 16 | |

| 329 | 1.4460 Nws | X3 CrNiMoN 27 5 2 | - | 2324 ib | F.3309 | - | |

| 321 | 1.4541 ib | X10 CrNiTi 18 9 | 321 Ib. 12 | 2337 ib | F.3553 | X6CrNiTi18 11 | |

| 347 ib | 1.4550 Nws | X10 CrNiNb 18 9 | 347 Ib. 17 | ib 2338 | F.3552 | X6CrNiNb18 11 | |

| 316 Ti | 1.4571 ib | X10 CrNiMoTi 18 10 | 320 Ib. 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 ib | X15 CrNiSi 20 12 | 309 Ib. 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 ib | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Stainless Hlau | S32750 | 1.4410 Nws | X 2 CrNiMoN 25 7 4 | - | 2328 ib | - | - |

| S31500 Nws | 1.4417 ib | X 2 CrNiMoSi 19 5 | - | 2376 ib | - | - | |

| S31803 | 1.4462 ib | X 2 CrNiMoN 22 5 3 | - | 2377 ib | - | - | |

| wb 32760 | 1.4501 Nws | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 ib | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Ferrous thiab Non-ferrous Khoom siv rau kev nqis peev Casting, Poob Wax Casting Txheej Txheem:

- • Grey Hlau: HT150, HT200, HT250, HT300, HT350; GJL-100, GJL-150, GJL-200, GJL-250, GJL-300, GJL-350; GG10-GG40.

- • Cov Hlau Hlau lossis Nodular Iron: GGG40, GGG50, GGG60, GGG70, GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- • Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

- • Hlau Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo... thiab lwm yam ntawm kev thov.

- • Stainless hlau: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 thiab lwm yam stainless hlau qib.

- • Brass, Liab Copper, Bronze los yog lwm yam tooj liab-raws li alloy hlau: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

- • Lwm cov ntaub ntawv raws li koj cov kev cai tshwj xeeb lossis raws li ASTM, SAE, AISI, ACI, DIN, EN, ISO, thiab GB qauv

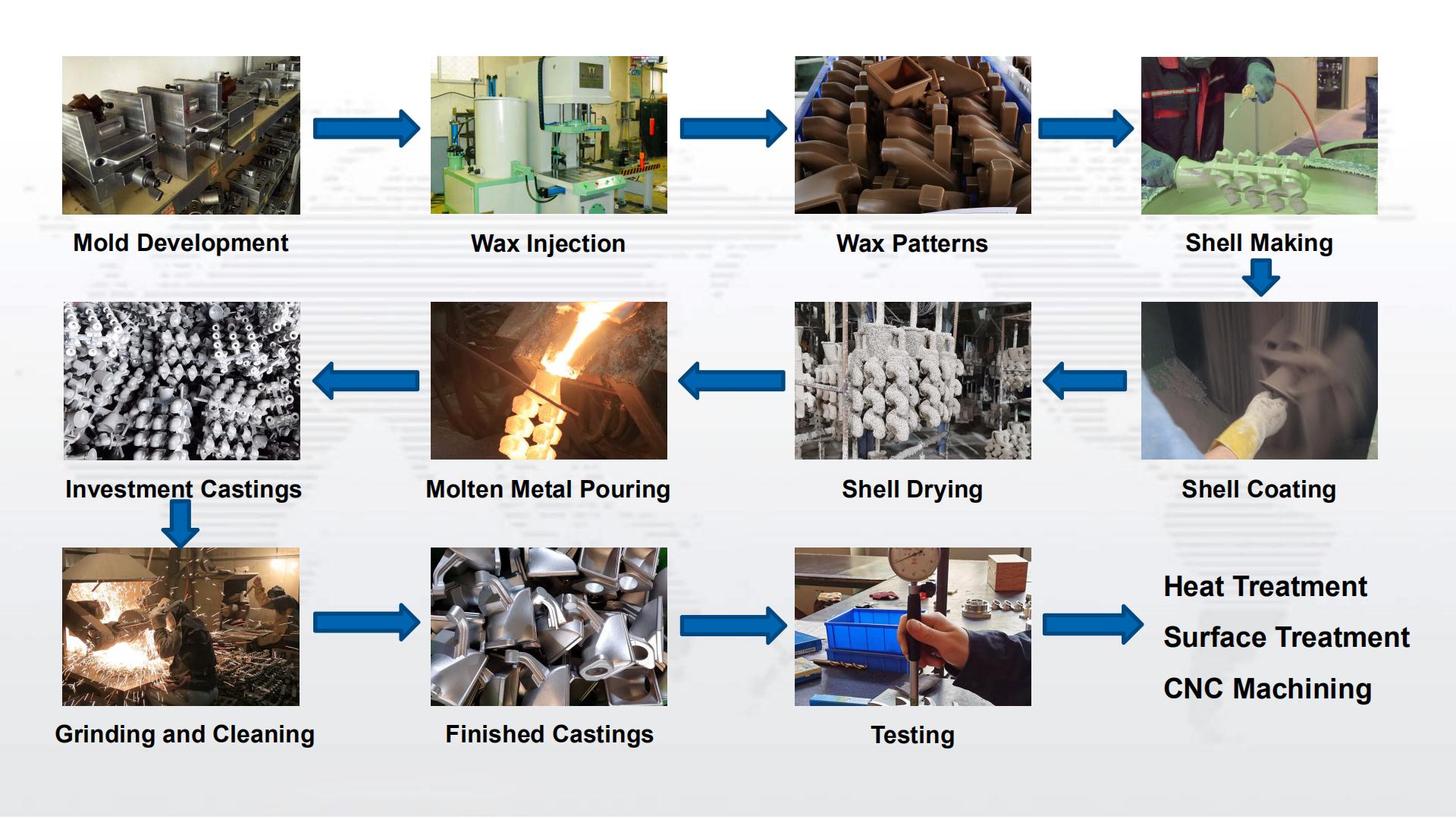

Cov kauj ruam koom nrog hauv cov txheej txheem los yog qhov poob ciab casting yog:

- • Tsim ib tug qauv siv quav ciab los yog replica

- • Sprue tus qauv siv quav ciab

- • nqis peev tus qauv siv quav ciab

- • Tshem tawm cov qauv siv quav ciab los ntawm kev hlawv nws (hauv qhov cub lossis hauv dej kub) los tsim cov pwm.

- • Force molten hlau ncuav rau hauv pwm

- • Txias thiab Solidification

- • Tshem tawm sprue ntawm cov castings

- • Ua kom tiav thiab polishing tiav cov peev txheej castings

Kev kho cua sov ntawm AISI 316 Stainless Hlau Castings:

Thaum tshav kub kub rau 1900 ° F (1040 ° C) yam tsawg kawg nkaus, tuav lub sij hawm txaus, quench hauv dej los yog txias ceev los ntawm lwm txoj kev. AISI 316 sib npaug rau CF8M / F316 thiab Suav Standard 0Cr17Ni12Mo2. AISI 314 yog molybdenum bearing hloov kho ntawm AISI 304 alloy thiab yog qhov sib npaug ntawm wrought CF8M Stainless hlau. Lub xub ntiag ntawm molybdenum tsub kom qhov dav dav corrosion tsis kam thiab tsis kam rau pitting los ntawm chlorides. Lub alloy yog siv nyob rau hauv me ntsis acidic thiab alkaline tej yam kev mob thiab tuav citric, oxalic thiab phosphoric acids.