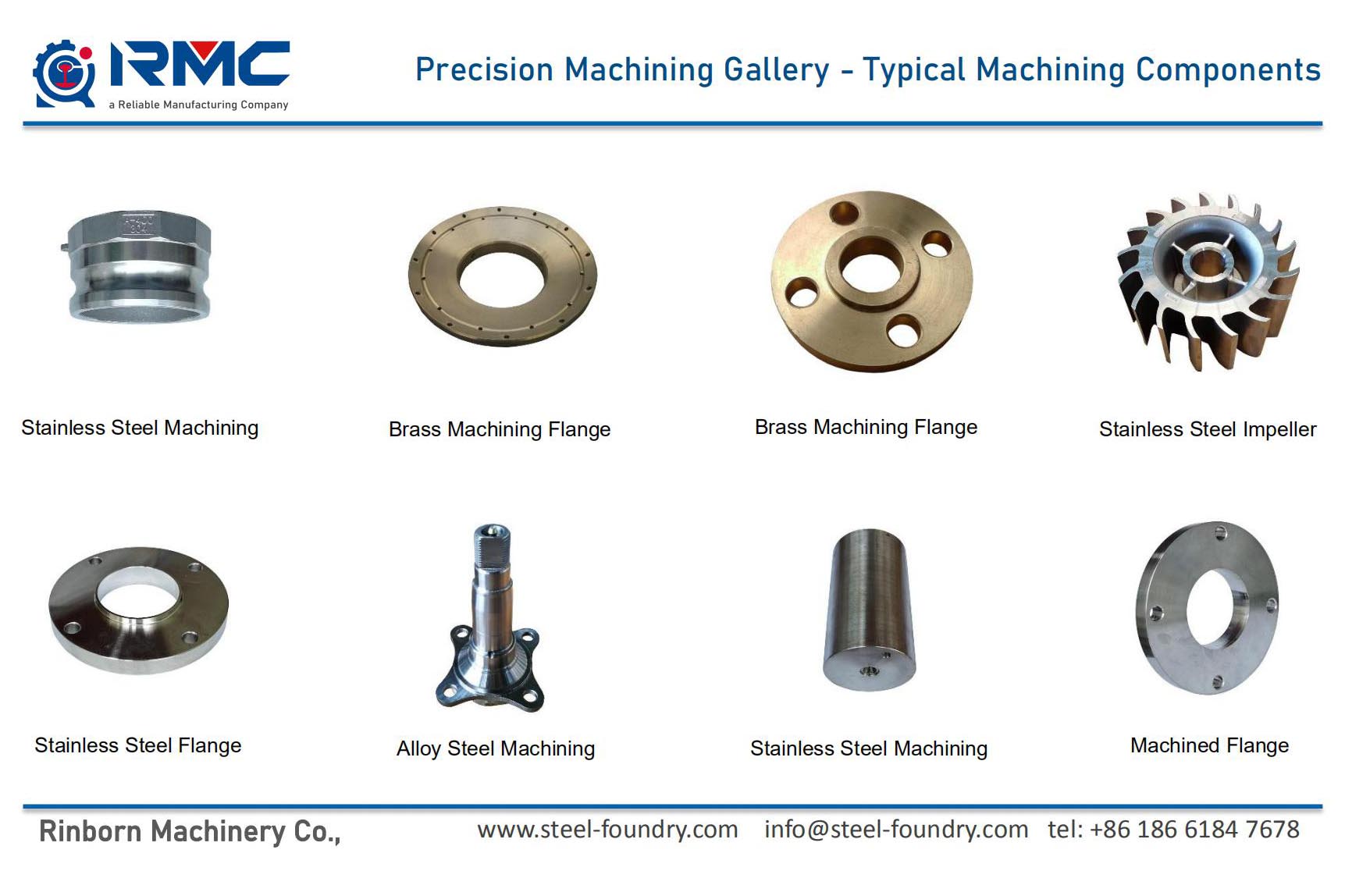

CNC precision machined tooj dag cov khoom lag luam los ntawm poob ciab peev casting, kev kho cua sov thiab kev kho deg raws li koj cov duab kos duab thiab cov kev cai tshwj xeeb.

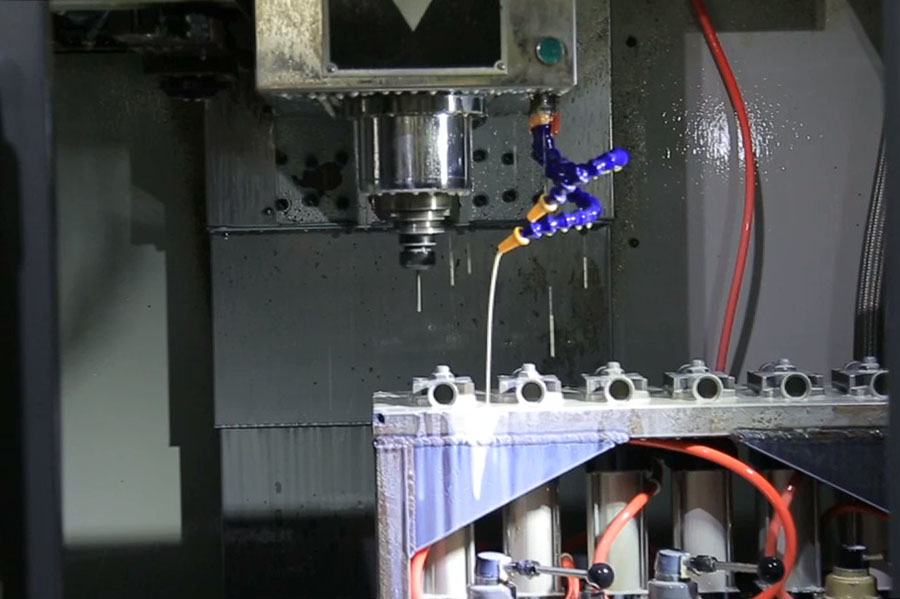

CNC machininghais txog cov txheej txheem machining pib los ntawm Computerized Numberical Control (CNC luv luv). Nws yog pab los ntawm CNC kom ncav cuag qhov tseeb thiab ruaj khov nrog cov nqi zog tsawg. Machining yog ib yam ntawm ntau yam txheej txheem uas ib daim ntawm raw khoom yog txiav mus rau hauv ib tug xav tau kawg cov duab thiab loj los ntawm ib tug tswj cov khoom-tshem tawm txheej txheem. Cov txheej txheem uas muaj cov ntsiab lus no, tswj cov khoom tshem tawm, yog niaj hnub no suav nrog kev tsim khoom tsim tawm, sib txawv los ntawm cov txheej txheem ntawm kev tswj cov khoom siv ntxiv, uas yog hu ua additive manufacturing.

Raws nraim li qhov "tswj" ib feem ntawm lub ntsiab lus txhais tau txawv, tab sis nws yuav luag txhua zaus siv cov cuab yeej siv tshuab (ntxiv rau cov cuab yeej hluav taws xob thiab cov cuab yeej tes). Qhov no yog txheej txheem siv los tsim ntau yamhlau machined khoom, tab sis nws kuj siv tau rau cov khoom xws li ntoo, yas, ceramic, thiab composites. CNC machining npog ntau yam txheej txheem xws li milling, tig, lathing, drilling, honing, sib tsoo ... thiab lwm yam.

tooj dag belongs rau lubtooj liab-raws li alloythiab yog ib qho alloy uas muaj tooj liab thiab zinc. Brass uas muaj tooj liab thiab zinc yog hu ua tooj dag zoo tib yam. Yog tias nws yog ntau hom alloys uas muaj ntau tshaj li ob lub ntsiab lus, nws yog hu ua tooj dag tshwj xeeb. Brass yog tooj liab alloy nrog zinc ua lub ntsiab tseem ceeb. Raws li zinc cov ntsiab lus nce, lub zog thiab plasticity ntawm cov alloy nce ntau, tab sis cov khoom siv kho tshuab yuav txo qis tom qab ntau tshaj 47%, yog li zinc cov ntsiab lus ntawm tooj dag yog tsawg dua 47%. Ntxiv nrog rau zinc, cam khwb cia tooj dag feem ntau muaj cov alloying xws li silicon, manganese, txhuas, thiab txhuas.

| CNC Precision Machining Muaj peev xwm | ||||

| Cov chaw | Ntau | Qhov Loj | Muaj peev xwm txhua xyoo | General raug |

| Vertical Machining Center (VMC) | 48set ib | 1500mm × 1000mm × 800mm | 6000 tuj los yog 300000 daim | ± 0.005 |

| Kab rov tav Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | 2000 tons lossis 100000 pieces | ± 0.005 |

| CNC tshuab | 60 sets | Max tig dia. φ600 hli | 5000 tons lossis 600000 daim | |

| Excutive Standard of Casting Tolerance: ISO 8062 2013, ISO 2768, GOST 26645 (Russia) lossis GBT 6414 (Tuam Tshoj). | ||||

Lub chaw machining yog tsim los ntawm CNC milling tshuab. Qhov sib txawv loj tshaj plaws los ntawm CNC milling tshuab yog tias lub chaw machining muaj peev xwm hloov pauv cov cuab yeej machining. Los ntawm kev txhim kho cov cuab yeej rau lub hom phiaj sib txawv ntawm cov cuab yeej magazine, cov cuab yeej machining ntawm lub spindle tuaj yeem hloov tau los ntawm cov cuab yeej hloov pauv tsis siv neeg hauv ib lub clamping kom paub ntau yam machining nta.

CNC machining chaw yog lub tshuab ua haujlwm siab ua haujlwm zoo uas yog tsim los ntawm cov cuab yeej siv tshuab thiab CNC system thiab tsim nyog rau kev ua haujlwm nyuaj. CNC machining chaw yog tam sim no yog ib qho ntawm feem ntau siv CNC tshuab cuab yeej nyob rau hauv lub ntiaj teb no nrog muaj zog ua tiav muaj peev xwm. Nws tuaj yeem ua tiav cov ntsiab lus ua tiav ntau dua tom qab lub workpiece clamped ib zaug. Kev ua kom raug yog siab. Rau batch workpieces nrog nruab nrab ua nyuaj nyuaj, nws efficiency yog 5-10 lub sij hawm ntawm cov cuab yeej zoo tib yam, tshwj xeeb tshaj yog nws muaj peev xwm ua tiav Ntau yam uas tsis tuaj yeem ua tiav los ntawm cov cuab yeej zoo tib yam yog tsim nyog rau ib qho kev ua haujlwm nrog ntau cov duab thiab cov kev xav tau siab los yog rau me me thiab nruab nrab batch ntau lawm ntau yam. Nws tsom rau kev ua haujlwm ntawm milling, tho txawv, drilling, tapping thiab txiav xov ntawm ib lub cuab yeej, kom nws muaj ntau yam kev siv tshuab.

| Qib sib piv ntawm tooj liab, tooj dag thiab tooj dag | |||||||

| Pawg | AISI | W-stoff | DIN | BS | JIS | EN | ISO |

| tooj liab | C10200 | 2.0040 Nws | OF Cu | C103 | C1020 | CWJ 008A | Cu-OF |

| C11000 Nws | 2, 0060 | e-cu57 | C101 | C1100 Nws | CWJ 004A | Cu-ETP | |

| - | 2.006 5 | e-cu58 | - | - | - | - | |

| C10300 Nws | 2.0070 Nws | SE Cu | - | - | qw 021a | - | |

| C12200 Nws | 2, 0090 | SF Cu | C106 | C1220 | qw 024a | Cu-DHP | |

| C12500 Nws | - | Cu-FRTP | C104 | - | CR006A | - | |

| c70320 ua | 2.0857 ib | - | - | - | CWJ 112 C | CuNi 3 Si | |

| C14200 Nws | 2.1202 Nws | SB Cu | C107 | - | - | Cu-AsP | |

| - | 2.1356 ib | Cu Mn 3 | - | - | - | - | |

| - | 2, 1522 | Cu Si 2 Mn | - | - | - | - | |

| C16200 Nws | - | C108 | - | - | CuCd 1 | ||

| C18200 Nws | - | TIAB SA 101 | - | CWJ 105 C | CuCr1 | ||

| C191010 Nws | - | - | - | CWJ 109C | CuNi1 Si | ||

| c70250 ua | - | TIAB SA 102 | - | CWJ 111 C | CuNi 2 Si | ||

| C17200 Nws | - | SIB 101 | - | CWJ 101C | CuB 2 | ||

| C17300 Nws | - | - | - | CWJ 102 C | CuBe2 Pb | ||

| c17510 ua | - | - | - | CWJ 110 C | CuNi2B | ||

| C17500 Nws | - | C112 | - | CWJ 104 C | CuCo2B | ||

| C15000 | - | - | - | CWJ 120 C | CuZr | ||

| c65100 ua | - | - | - | CWJ 115 C | CuSi2Mn | ||

| c65500 ua | - | TIAB SA 101 | - | CWJ 116C | CuSi3Mn1 | ||

| C14500 Nws | - | C109 | - | CWJ 118C | CuTeP | ||

| C14700 Nws | - | C111 | - | CWJ 114 C | CuSP | ||

| C18700 Nws | - | - | - | CWJ 113 C | kub 1p | ||

| BRASS | C21000 | 2.0220 Nws | CuZn 5 | CZ125 | C2100 | CWJ 500L | - |

| C22000 | 2.0230 Nws | CuZn10 | Cz101 | C2200 | qw 501l | - | |

| C23000 | 2.0240 Nws | CuZn15 | CZ102 | C2300 Nws | qw 502l | - | |

| C24000 | 2.0250 Nws | CuZn 20 | CZ103 | C2400 Nws | qw 503l | - | |

| c25600 ua | - | CuZn28 | - | - | - | - | |

| C26000 | 2.0265 ib | CuZn30 | CZ106 | C2600 Nws | qw 505l | - | |

| c26800 ua | 2.0280 Nws | CuZn33 | - | c2680 ua | qw 506l | - | |

| c27200 ua | - | CuZn36 | - | - | - | - | |

| c27200 ua | 2.0321 ib | CuZn37 | CZ108 | C2700 Nws | qw 508l | - | |

| C27000 Nws | 2, 0335 | CuZn36 | CZ107 | C2700 Nws | qw 507l | - | |

| C28000 Nws | 2.0360 ib | CuZn 40 | CZ109 | C2800 Nws | qw 509l | - | |

| c33500 ua | - | CuZn37Pb 0.5 | - | - | - | - | |

| C34000 | - | CuZn35Pb1 | CZ118 | c3501 ua | - | - | |

| c34500 ua | 2.0331 ib | CuZn36Pb1,5 | CZ119 | - | CWJ 601 N | - | |

| C34000 | 2.0331 ib | CuZn36Pb1,5 | CZ119 | c3501 ua | CW 600 N | - | |

| c35300 ua | 2.0371 ib | CuZn38Pb1,5 | CZ128 | - | - | - | |

| c36500 ua | 2.0372 ib | CuZn39Pb0,5 | CZ123 | - | CWJ 610 N | - | |

| C36000 | 2.0375 ib | CuZn36 Pb 3 | CZ124 | c3601 ua | qw 603n | - | |

| c37700 ua | 2.0380 Nws | CuZn39pb 2 | CZ 131 / (CZ128) | c3771 ua | CWJ 612 N | - | |

| c38500 ua | 2.040 1 | CuZn39 Pb 3 | CZ121 | c3603 ua | qw 614n | - | |

| C38000 | 2.040 2 | CuZn40Pb 2 | CZ122 | - | qw 617n | - | |

| - | 2.0410 Nws | CuZn44Pb 2 | CZ130 | - | - | - | |

| c68700 ua | 2.0460 ib | CuZn20Al2 | CZ110 | - | - | - | |

| c44300 ua | 2.0470 ib | CuZn28Sn1 | CZ111 | - | - | - | |

| - | 2.0530 Nws | CuZn38Sn1 | - | - | - | - | |

| - | 2.0550 Nws | CuZn40Al2 | - | - | - | - | |

| - | 2.0561 ib | CuZn40Al1 | - | - | - | - | |

| - | 2.0572 ib | CuZn40Mn 2 | CZ136 | - | qw 723r | - | |

| c61400 ua | 2.0932 ib | CuAl8Fe 3 | - | - | qw 303g | - | |

| c63000 ua | 2.0966 ib | CuAl10Ni5Fe4 | TIAB SA 104 | - | qw 307g | - | |

| BRONZE | c50700 ua | 2.1010 Nws | CuSn 2 | - | - | - | - |

| C51100 | 2.1016 Nws | CuSn4 | PB 101 | c5111 ua | CWJ 450 K | - | |

| C51000 | - | CuSn5 | PB 102 | c5102 ua | qw 451k | - | |

| c51900 ua | 2.1020 Nws | CuSn6 | PB 103 | c5191 ua | qw 452k | - | |

| C52100 | 2.1030 Nws | CuSn8 | PB 104 | c5212 ua | qw 453k | - | |

| - | - | CuSn10 | - | - | - | - | |

| - | - | CUSn11 | - | - | - | - | |

| - | - | CuSn12 | - | - | - | - | |

Machining chaw muab faib rau hauv kab rov tav thiab ntsug machining chaw raws li lawv txoj haujlwm spatial thaum spindle machining. Muab faib raws li txheej txheem siv: tho txawv thiab milling machining chaw, compound machining chaw. Raws li kev faib tshwj xeeb ntawm kev ua haujlwm, muaj xws li: ib leeg workbench, ob chav workbench thiab multi-workbench machining chaw. Machining chaw nrog ib leeg-axis, dual-axis, peb-axis, plaub-axis, tsib-axis thiab interchangeable headstocks, thiab lwm yam.

CNC machining yog hom precision machining los ntawm CNC tshuab xws li advanced machining chaw uas muaj sab saum toj kawg 5 axis machining chaw, 4 axis ob chav platform machining chaw, los yog CNC tig lathes uas kuj yuav tsim tau rau CNC tig chaw muaj peev xwm hloov tau ntau dua. ntau tshaj 15 cutters nyob rau hauv ib tug tuav hloov; CNC milling tshuab thiab CNC drilling thiab tapping chaw. Precision machining ntawm steel casting yog txawv ntawm machining ntawm steel profile. Precision casting twb ua tiav cov duab zoo heev ntawm qhov xav tau, yog li nws txuag ntau ntawm machining piv nrog machining los ntawm steel profile ncaj qha. Tsis tas li vim yog vim li cas, peb feem ntau yuav tsum xav txog qhov chaw ua haujlwm thiab cov nyiaj ua haujlwm zoo ua ntej casting. Peb qhov kev yuav khoom tsis tu ncua yog ua haujlwm tawm cov duab kos duab nrog rau kev kos duab kos duab kom meej meej machining cheeb tsam thiab machining nyiaj pub dawb ntawm daim duab.

RMC peev casting foundry tau nruab nrog 4 axis machining chaw, 15 teeb ntawm CNC tig lathes thiab 3 txheej ntawm cnc milling tshuab, nrog rau kev pab ntau yam tig, milling, tapping, drilling thiab sib tsoo tshuab, peb muaj peev xwm ntawm machining ze li ntawm tag nrho cov. hom steel castings.

Kuj hu ua precision machining, CNC machining tuaj yeem ncav cuag qhov raug siab heev hauv geometical kam rau ua thiab qhov ntev ntev. Nrog peb cov tshuab CNC thiab Kab rov tav Machining Centers (HMC) thiab Vertical Machining Centers (VMC), peb tuaj yeem ua tau raws li tag nrho koj cov qib siab kam rau ua.

Peev xwm ntawmKev nqis peev Casting Foundry:

• Max Loj: 1,000 mm × 800 mm × 500 mm

• Qhov hnyav: 0.5 kg - 100 kg

• Ib xyoos twg muaj peev xwm: 2,000 tons

• Bond Materials for Shell Building: Silica Sol, Dej iav thiab lawv cov khoom sib tov.

• Tolerances: Thaum Thov.

Qhov zoo ntawmKev nqis peev Casting Cheebtsam:

- Zoo heev thiab du nto tiav

- Tight dimensional tolerances.

- Cov duab sib txawv thiab sib txawv nrog kev tsim qauv yooj yim

- Muaj peev xwm cam khwb cia nyias phab ntsa yog li ib tug sib zog casting tivthaiv

- Kev xaiv dav ntawm cam khwb cia hlau thiab alloys (ferrous thiab non-ferrous)

- Cov qauv tsis tas yuav tsum muaj nyob rau hauv kev tsim pwm.

- Txo qhov xav tau rau kev ua haujlwm thib ob.

- Cov khoom siv tsawg tsawg.

| INVESTMENT CASTING TOLERANCES | |||

| Ntiv | millimeters | ||

| Dimension | Ua siab ntev | Dimension | Ua siab ntev |

| Mus txog 0.500 | ± .004 " | Mus txog 12.0 | ± 0.10 hli |

| 0.500 rau 1.000 " | ± 006 " | 12.0-25.0 Nws | ± 0.15 hli |

| 1.000 rau 1.500 " | ± 008 " | 25.0-37.0 Nws | ± 0.20 hli |

| 1.500 rau 2.000 " | ± .010 " | 37.0-50.0 Nws | ± 0.25 hli |

| 2.000-2.500 " | ± .012 " | 50.0 rau 62.0 | ± 0.30 hli |

| 2.500 rau 3.500 " | ± .014 " | 62.0 rau 87.0 | ± 0.35 hli |

| 3.500 rau 5.000 " | ± .017 " | 87.0 rau 125.0 | ± 0.40 hli |

| 5,000 rau 7,500 " | ± .020 " | 125.0 rau 190.0 | ± 0.50 hli |

| 7.500-10.000 " | ± 022 " | 190.0 rau 250.0 | ± 0.57 hli |

| 10,000 rau 12,500 " | ± .025 " | 250.0 rau 312.0 | ± 0.60 hli |

| 12.500-15.000 Nws | ± 028 " | 312.0 rau 375.0 | ± 0.70 hli |