OEM kev cai nqus casting khoom ntawm grey hlau thiab spheroidal graphite (SG) ductile nodular cam khwb cia hlau nrog tshav kub kev kho mob, nto kho thiab CNC machining kev pab cuam.

Nqus Casting tseem hu ua Negative Pressure Sealed Casting, Reduced Pressure Casting lossis V Process Casting. Lub tshuab nqus tsev siab casting yuav tsum tau siv cov cuab yeej siv cua tshem tawm kom tshem tawm cov huab cua hauv cov pwm pwm, thiab tom qab ntawd siv qhov sib txawv ntawm qhov sib txawv ntawm cov pwm sab hauv thiab sab nraud los npog cov yas zaj duab xis rau cov qauv thiab cov qauv. Lub casting pwm yuav muaj zog txaus los tiv thaiv cov hlau molten thaum lub sij hawm casting. Tom qab tau txais lub tshuab nqus tsev pwm, sau lub thawv xuab zeb nrog cov xuab zeb qhuav yam tsis muaj binder, thiab tom qab ntawd muab cov xuab zeb ntim rau saum npoo nrog cov yas zaj duab xis, ua raws li lub tshuab nqus tsev kom cov xuab zeb ruaj khov thiab nruj. Tom qab ntawd, tshem tawm cov pwm, muab cov xuab zeb cores, kaw lub pwm kom txhua yam npaj txhij rau pouring. Thaum kawg, lub casting yog tau tom qab lub molten hlau yog txias thiab solidified.

| Poob Foam Casting vs Nqus Casting | ||

| Yam khoom | Poob Foam Casting | Nqus Casting |

| Tsim nyog Castings | Me me thiab nruab nrab-qhov loj me castings nrog complex kab noj hniav, xws li cav thaiv, cav npog | Nruab nrab thiab loj castings nrog ob peb los yog tsis muaj kab noj hniav, xws li cam khwb cia hlau counterweights, cam khwb cia hlau qag tsev |

| Cov qauv thiab daim phiaj | Ua npuas ncauj qauv ua los ntawm moldings | Template nrog suction box |

| Sand Box | Hauv qab lossis tsib sab tso tawm | Plaub sab tso tawm lossis nrog cov yeeb nkab tso tawm |

| Yas Zaj duab xis | Sab saum toj npog yog kaw los ntawm cov yas zaj duab xis | Txhua sab ntawm ob qho tib si ntawm lub thawv xuab zeb yog kaw los ntawm cov yeeb yaj kiab yas |

| Cov ntaub ntawv txheej | Dej-raws li xim pleev xim nrog tuab txheej | Cawv-raws li xim pleev xim nrog nyias txheej |

| Moulding Xuab zeb | Coarse qhuav xuab zeb | Zoo qhuav xuab zeb |

| Vibration Moulding | 3D kev vibration | Vertical lossis Kab rov tav vibration |

| Ncuav | Cov dej tsis zoo | Cov dej tsis zoo |

| Xuab zeb txheej txheem | Tshem tawm lub siab tsis zoo, tig lub thawv kom tso cov xuab zeb, thiab cov xuab zeb rov qab siv dua | Tshem tawm qhov tsis zoo siab, ces cov xuab zeb qhuav poob rau hauv qhov screen, thiab cov xuab zeb rov qab siv dua |

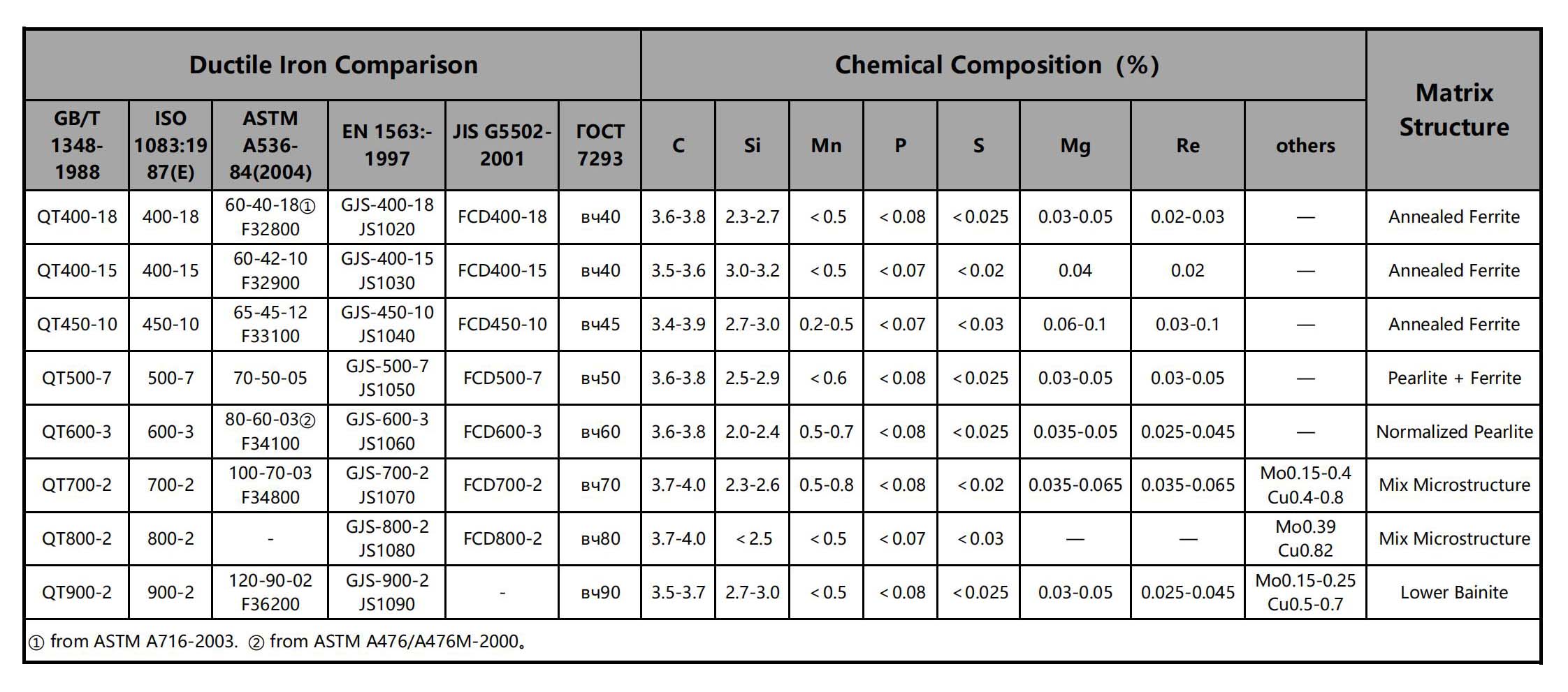

Ductile cam khwb cia hlau, uas tseem hu ua nodular cam khwb cia hlau, spheroidal graphite cam khwb cia hlau los yog SG hlau luv luv, sawv cev rau ib pawg ntawm cam khwb cia hlau. Nodular cam khwb cia hlau tau txais nodular graphite los ntawm spheroidization thiab inoculation kev kho mob, uas zoo txhim kho cov neeg kho tshuab zog ntawm cov cam khwb cia hlau, tshwj xeeb tshaj yog cov yas thiab toughness, thiaj li yuav tau txais lub zog siab dua carbon steel.

Cov hlau castings muaj kev poob siab zoo dua li cov hlau, thaum cov hlau castings muaj qhov zoo dua weldability. Thiab rau qee qhov, cov ductile iorn castings tuaj yeem muaj qee qhov kev ua yeeb yam ntawm kev hnav thiab xeb. Yog li cov hlau nplaum hlau tuaj yeem siv rau qee lub twj tso kua mis lossis cov khoom siv dej. Txawm li cas los xij, peb tseem yuav tsum tau ceev faj tiv thaiv lawv ntawm kev hnav thiab xeb.

Ductile hlau tsis yog ib qho khoom siv xwb tab sis yog ib feem ntawm cov khoom siv uas tuaj yeem tsim kom muaj ntau yam khoom los ntawm kev tswj hwm ntawm microstructure. Lub ntsiab lus txhais cov yam ntxwv ntawm pawg ntawm cov ntaub ntawv no yog cov duab ntawm graphite. Hauv cov hlau nplaum, cov graphite yog nyob rau hauv daim ntawv ntawm nodules es tsis yog flakes li nws yog nyob rau hauv grey hlau. Lub ntsej muag zoo nkauj ntawm cov flakes ntawm graphite tsim cov ntsiab lus kev ntxhov siab nyob rau hauv cov hlau matrix thiab cov duab sib npaug ntawm cov nodules tsawg dua, yog li inhibiting kev tsim cov kab nrib pleb thiab muab cov ductility zoo dua uas muab cov hlau nws lub npe. Yog li feem ntau hais lus, yog tias cov hlau nplaum tuaj yeem ua tau raws li koj qhov yuav tsum tau ua, cov hlau nplaum tuaj yeem yog koj thawj qhov kev xaiv, es tsis txhob carbon steel rau koj cov castings.