cam khwb cia hlau, uas tsuas yog npog grey cam khwb cia hlau, cam khwb cia hlau cam khwb cia hlau, cam khwb cia mealleable hlau thiab lwm yam siab alloy cam khwb cia hlau, yog dav siv nyob rau hauvRMC Casting Foundry. Cov cam khwb cia hlau castings ua lub luag haujlwm tseem ceeb hauvniaj hnub kev lag luam. Txhawm rau xaiv txoj cai thiab tsim cov txheej txheem casting ua los ntawm cam khwb cia hlau yuav pab koj kom tau cov hlau castings ntawm tus nqi qis thiab luv luv leadtime.

Ntawm no hauv qab no peb nthuav tawm qee lub hauv paus ntsiab lus lossis yam tseem ceeb thaum peb xaivtsim nyog cov txheej txheem castingrau cov khoom siv hlau cam khwb cia. Feem ntau hais lus, feem ntau siv hlau casting txheej txheem yog xuab zeb casting, ua raws li kev tshwj xeeb casting, xws li hlau pwm casting, peev casting, plhaub molding casting,poob ua npuas ncauj castingthiab nqus casting.

1- Xuab zeb Casting yuav tsum yog thawj qhov kev xaiv

Feem ntau yog vim tus nqi qis thiab kev tsim khoom yooj yim ntawmxuab zeb casting txheej txheem, xuab zeb casting tau siv li 60% mus rau 70% ntawm tag nrho cov casting ntau lawm, thiab li ntawm 70% ntawm uas yog ntsuab xuab zeb casting. Thaum cov xuab zeb ntsuab tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua thiab tom qab ntawd koj tuaj yeem xav txog kev siv cov xuab zeb qhuav lossis lwm yam xuab zeb. Qhov hnyav ntawm ntsuab xuab zeb casting yog los ntawm ob peb kilograms mus rau pua pua kilograms, thaum qhuav av nplaum casting yuav hnyav ntau tons.

Cov txheej txheem xuab zeb casting siv hom xuab zeb los ua pwm pwm. Nws tseem tuaj yeem muab faib ua peb hom:

1) Ntsuab Sand Casting, uas siv cov xuab zeb ntub (ntsuab) los tsim cov pwm.

2) Resin Coated Sand Castingthiab Tsis muaj ci Sand Pwm Casting (Self-hardening Resin Sand Casting), uas siv cov khoom siv tshuaj sib txuas los pab tsim cov tshuab molding.

3) Qhuav Sand Casting, uas tsuas yog siv cov qhuav yam tsis muaj tshuaj mateials rau molding. Cov xuab zeb qhuav txheej txheem feem ntau yog hais txog kev poob ua npuas ncauj thiabnqus casting.

Feem ntau hais lus, rau nruab nrab thiab loj hlau castings, tus kheej-hardening resin xuab zeb casting yuav yog qhov kev xaiv zoo. Tab sis hais txog cov hlau alloy thiab cov ntaub ntawv carbon steel, peb tuaj yeem xaiv cov dej iav xuab zeb. Qhov no tuaj yeem tau txais qhov tseeb qhov ntev, du nto ntawm cov castings, thaum nrog tus nqi qis dua silica sol peev casting txheej txheem.

Qhov tseeb, nto tiav, cov khoom siv ntom ntom thiab microstructure, cov khoom siv kho tshuab yuav tsis ncav cuag qhov kev xav tau nruj yog tias koj muaj kev cia siab tshwj xeeb thiab siab. Nyob rau hauv rooj plaub no, lwm txoj kev casting xws li silica sol lossis dej iav peev casting, tuag casting, tsis tshua muaj siab casting, poob ua npuas ncauj casting thiab nqus casting yuav tsum tau muab coj los rau hauv peb lub qhov muag.

2- Xav Txog Kev Xav Tau Txhua Xyoo

Yog tias koj qhov kev thov txhua xyoo yog siab, cov kab molding tsis siv neeg yuav tsum yog qhov kev xaiv zoo tshaj plaws vim nws muaj peev xwm ntau lawm thiab ruaj khov. Thiab txoj kev no tuaj yeem ncav cuag tus nqi nruab nrab qis tsuas yog tias qhov xav tau kom muaj ntau txaus. Thaum, molding los ntawm tes yuav txuag koj cov nqi yog tias koj qhov ntau tsis loj, lossis koj qhov kev xav tau yog qhov nruab nrab lossis loj.

Txawm li cas los xij, resin xuab zeb pwm (plhaub moulding) txheej txheem casting kuj yog tsim rau hlau castings loj loj. Ntxiv mus, lub plhaub casting muaj kev ua tiav zoo dua thiab zoo dua li cov txheej txheem xuab zeb ntsuab.

Lwm cov txheej txheem xws li tsis tshua muaj siab tuag casting, tuag casting, centrifugal casting tsuas yog tsim rau huab hwm coj ntau lawm vim yog cov khoom kim heev thiab cov cuab yeej siv.

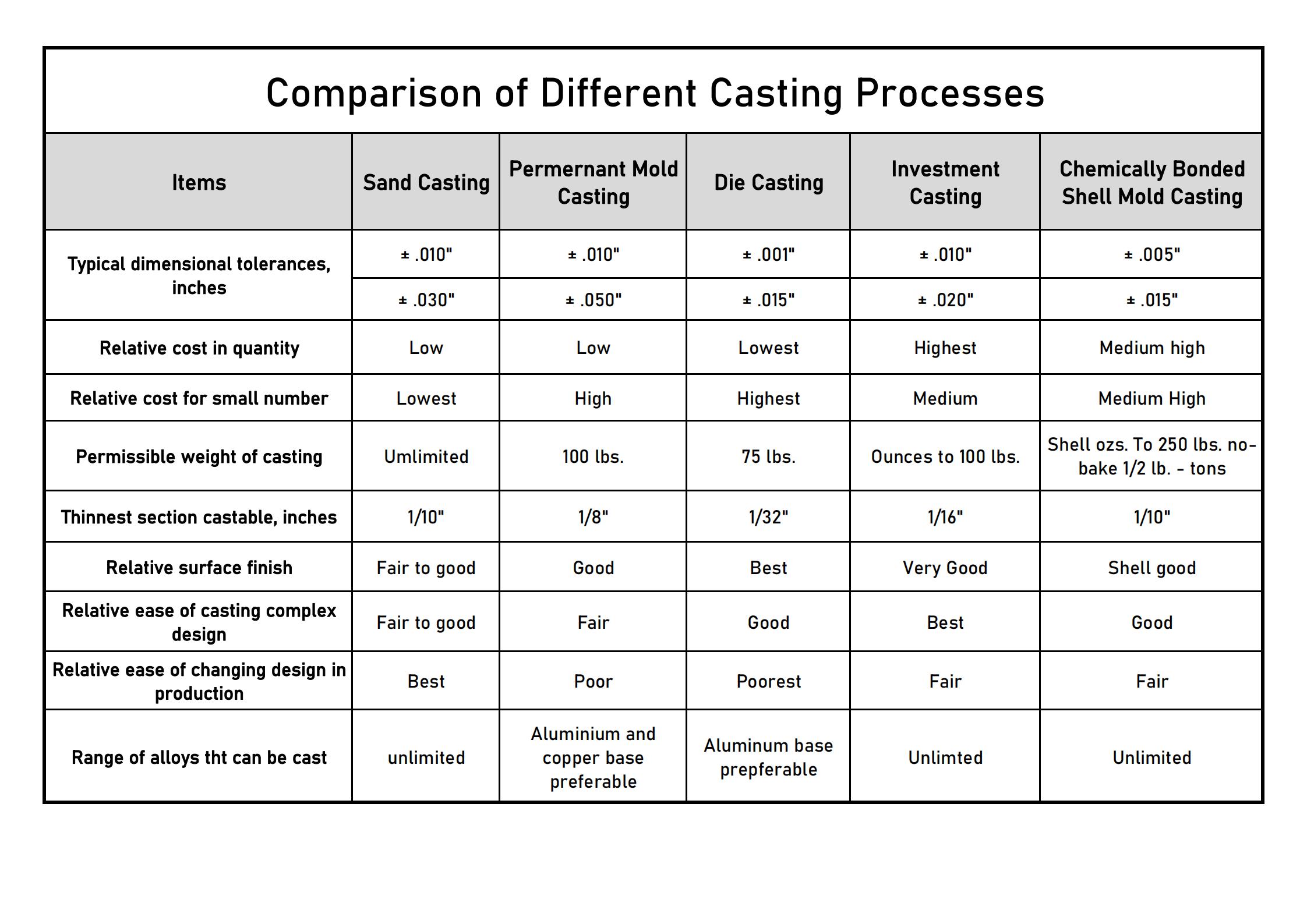

3- Dimensional Tolerances thiab Surface Quality Count

Nyob rau hauv tus txheej txheem ntawm kev xaiv cov txheej txheem casting rau cov khoom siv hlau cam khwb cia, qhov tseeb qhov tseeb thiab qhov zoo ntawm qhov chaw kuj tseem ceeb heev. Xaiv ibprecision casting txheej txheemyuav txo qhov xav tau ntawm machining, txawm tias tsis muaj machining. Qhov no yuav tsum muaj kev txiav txim siab zoo ntawm qhov sib npaug ntawm qhov nce ntawm cov nqi casting thiab txo cov machining. Raws li peb cov kev paub ntau xyoo, peb lub tuam txhab engineers tuaj yeem xaiv cov txheej txheem casting zoo tshaj plaws rau koj.

Post lub sij hawm: Jan-28-2021