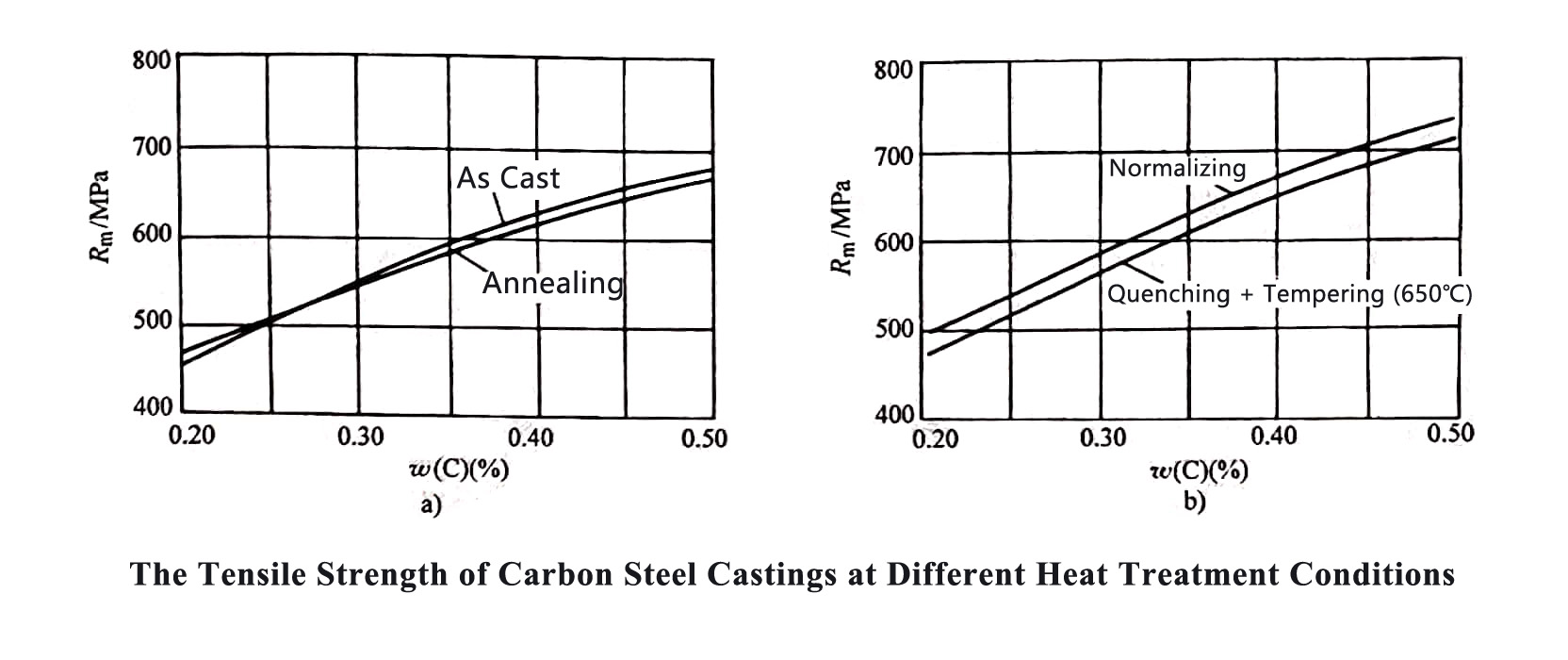

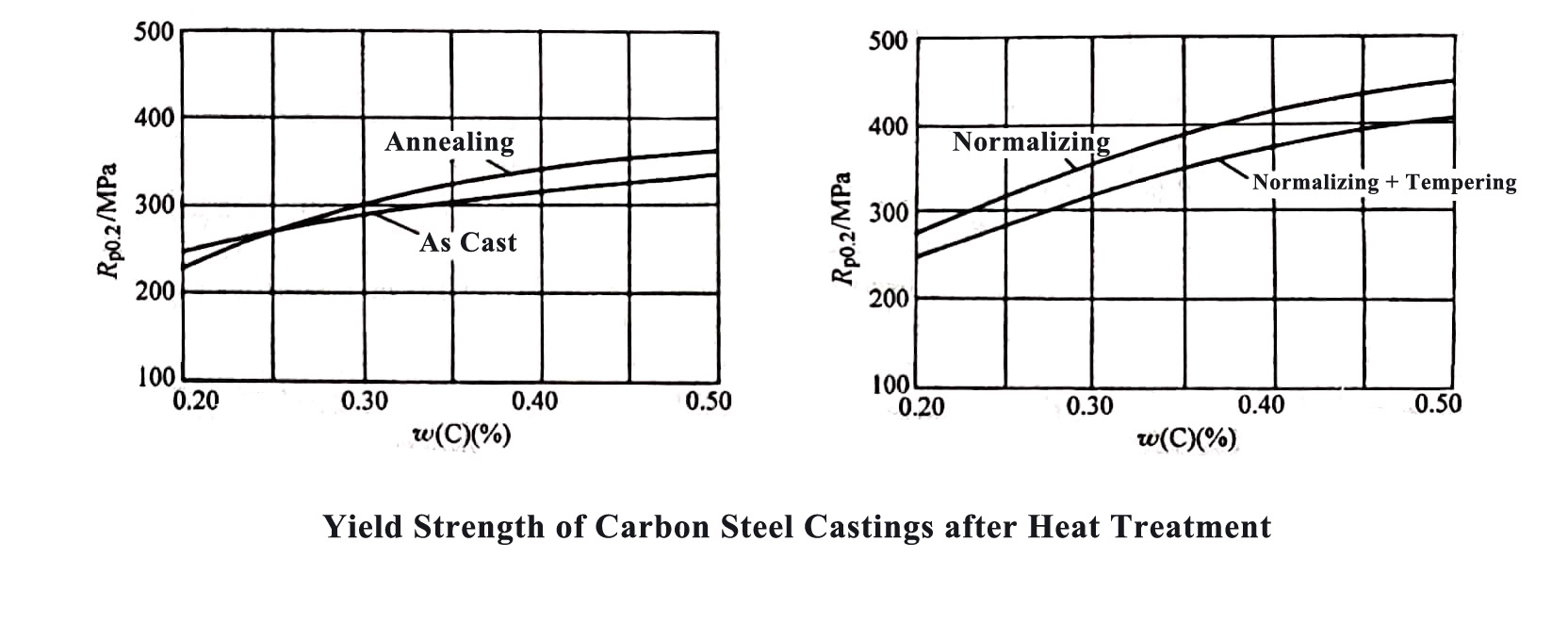

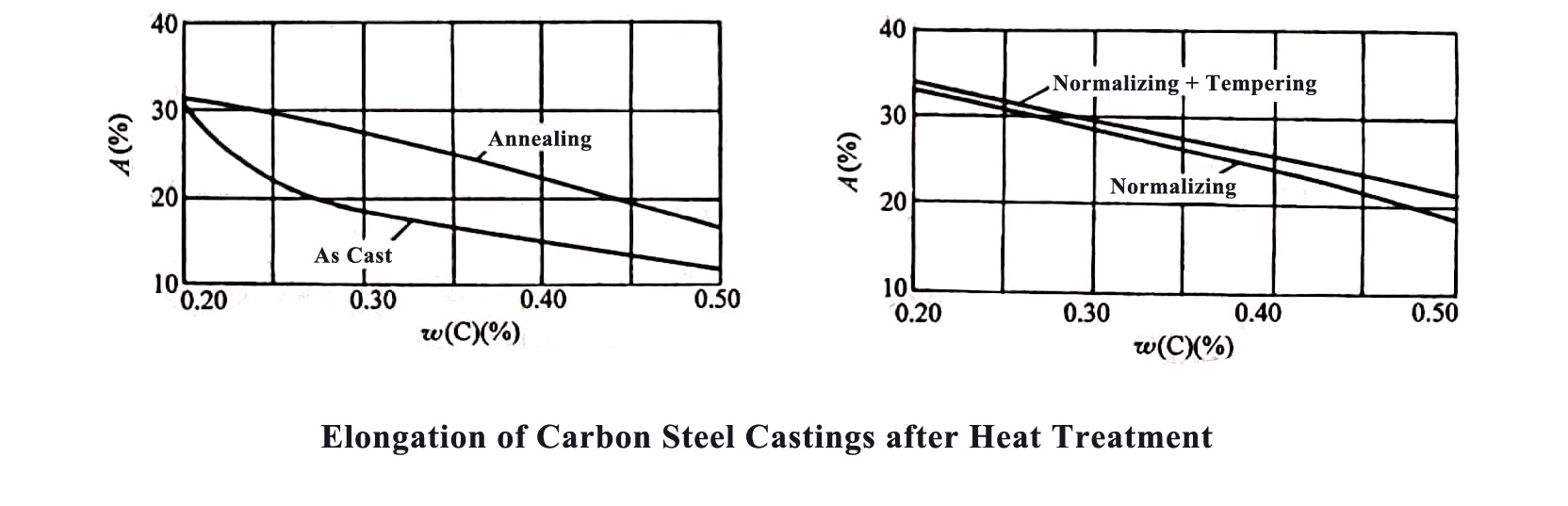

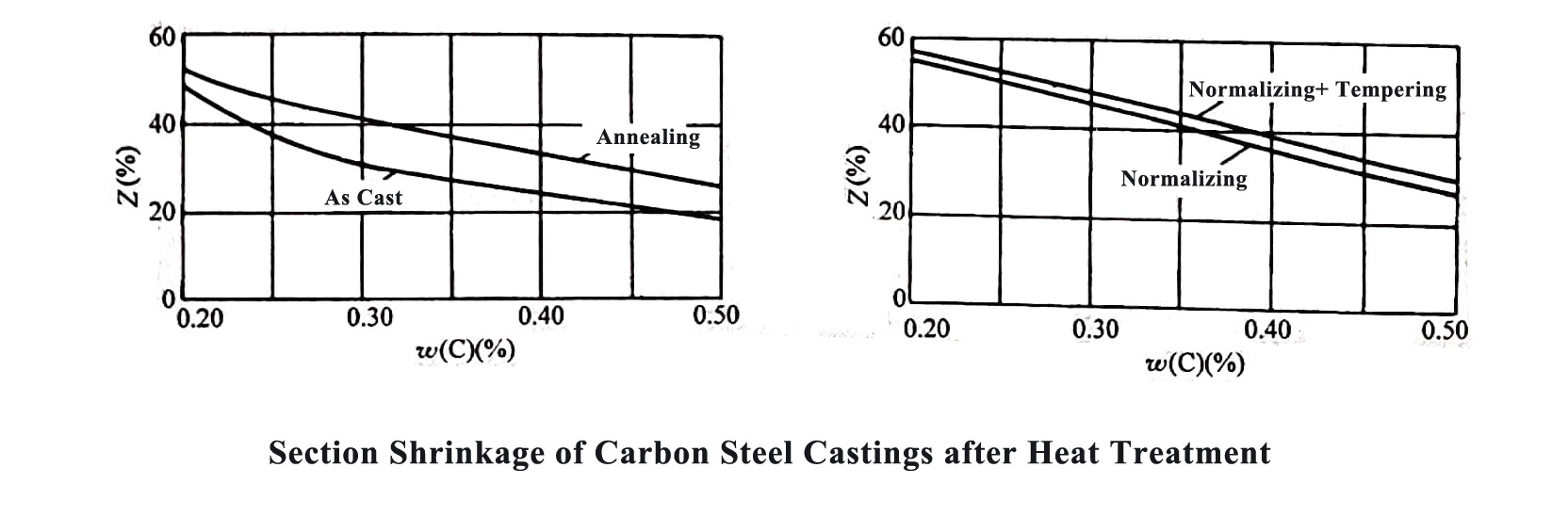

Cov txheej txheem kev kho cua sov feem ntau yog siv rau carbon steel castings yog: annealing, normalizing lossis normalizing + tempering. Kev cuam tshuam ntawm peb txoj kev kho cua sov no ntawm cov khoom siv hluav taws xob ntawm cov cam khwb cia carbon steel yog qhia hauv daim duab hauv qab no.

| Lub Annealing Kub thiab Hardness ntawm Carbon Steel Castings | ||||||

| Qib ntawm Carbon Steel | Cov ntsiab lus carbon /% | Annealing kub / ℃ | Tuav Sijhawm | Txoj kev txias | Hardness / HBW | |

| Phab ntsa Thickness / mm | Sijhawm / h | |||||

| ZWG 200 - 400 | 0.10-0.20 Nws | 910-880 ib | 30 | 1 | Ua kom txias rau 620 ℃ hauv cov cua sov thiab tom qab ntawd txias hauv huab cua | 115-143 : kuv |

| ZWM 230-450 | 0.20-0.30 Nws | 900-870 Nws | 133-156 : kuv | |||

| ZWM 270-500 | 0.30-0.40 Nws | 890-860 ib | 143-187 : kuv | |||

| ZWM 310-570 | 0.40-0.50 Nws | 870-840 ib | 30-100 | nce 1 teev / 30 mm | 156-127 : kuv | |

| ZWM 340-640 | 0.50-0.60 Nws | 860-830 ib | 187-230 ib | |||

Cov khoom siv ntawm cov hlau tsis zoo yog me ntsis siab dua li cov hlau cam khwb cia hlau. Raws li cov degree ntawm undercooling thaum lub sij hawm hloov ntawm cov qauv yog qhov loj, lub hardness yuav siab dua, thiab nws cov kev ua tau zoo kuj zoo dua.

| Lub Normalizing thiab Hardness ntawm Carbon Steel Castings | |||||

| Qib ntawm Carbon Steel | Cov ntsiab lus carbon (%) | Normalizing Kub / ℃ | Tempering | Hardness / HBW | |

| Kub / ℃ | Txoj kev txias | ||||

| ZWG 200 - 400 | 0.10-0.20 Nws | 930-890 Ib | 540-610 ib | hauv qhov cub lossis cua | 126-149 : kuv |

| ZWM 230-450 | 0.20-0.30 Nws | 930-890 Ib | 540-610 ib | hauv qhov cub lossis cua | 139-169 : kuv |

| ZWM 270-500 | 0.30-0.40 Nws | 890-860 ib | 550-620 : kuv | hauv qhov cub lossis cua | 149-187 : kuv |

| ZWM 310-570 | 0.40-0.50 Nws | 890-850 ib | 550-650 | hauv qhov cub lossis cua | 163-217 : kuv |

| ZWM 340-640 | 0.50-0.60 Nws | 870-830 ib | 550-650 | hauv qhov cub lossis cua | 187-228 : kuv |

Rau cov pa roj carbon steel castings nrog cov ntsiab lus carbon siab thiab cov duab nyuaj, txhawm rau txhawm rau tshem tawm cov kev ntxhov siab thiab txhim kho toughness, tempering kev kho mob tuaj yeem nqa tawm tom qab normalizing. Tempering kub yog feem ntau 550 ℃ -650 ℃, thiab tom qab ntawd txias hauv huab cua.

Thaum cov ntsiab lus carbon siab dua 0.35%, cov cam khwb cia carbon steel qhov chaw kuj tuaj yeem quenched thiab tempered (quenched + kub tempered). Me me carbon steel castings tuaj yeem ncaj qha quenched thiab tempered nyob rau hauv lub xeev as-cam khwb cia; loj los yog complex-shaped carbon steel castings yuav tsum tau quenched thiab tempered tom qab normalizing.

| Lub quenching thiab tempering kub thiab hardness ntawm carbon hlau Castings | |||

| Cov ntsiab lus carbon% | Quenching Kub / ℃ | Tempering Kub / ℃ | Hardness Tom qab Tempering / HBW |

| 0.35 - 0.45 (Batch me) | 850 - 830 (Txias hauv dej) | 300-400 | 364-444 Ib |

| 400-450 | 321-415 : kuv | ||

| 510-550 ib | 241-286 : kuv | ||

| 540-580 : kuv | 228-269 : kuv | ||

| 580-640 Ib | 192-228 : kuv | ||

| 0.45 - 0.55 (Batch me) | 830 - 810 (Txias hauv dej lossis roj) | 550-630 : kuv | 220-240 ib |

| 450 | ≈ 269 | ||

| 550 | ≈ 248 | ||

| 650 | ≈ 228 | ||

| 0.30 - 0.40 (Hloov ntau) | 840-880 (Txias hauv dej lossis roj) | 520-550 ib | 229-269 : kuv |

| 530-560 ib | 217-255 : kuv | ||

| 540-570 ib | 207-241 : kuv | ||

| 550-580 ib | 187-229 : kuv | ||

| 0.40 - 0.50 (Mass Batch) | 820 - 840 (Txias hauv dej lossis roj) | 530-560 ib | 229-269 : kuv |

| 550-580 ib | 217-255 : kuv | ||

| 560-590 ib | 207-241 : kuv | ||

| 570-600 Nws | 187-229 : kuv | ||

Post lub sij hawm: Lub Xya hli ntuj-23-2021