Solidification Mechanisms

Thaum lub sij hawm casting txheej txheem, lub solidification ntawm castings tshwm sim thaum lub molten hlau hloov los ntawm ib tug kua mus rau ib tug khoom lub xeev. Cov txheej txheem no tuaj yeem faib dav rau hauv peb lub tshuab:nucleation, dendritic kev loj hlob, thiabgrain qauv tsim. Thaum lub sij hawm nucleation, cov khoom me me tsim nyob rau hauv cov kua hlau. Cov nuclei loj hlob mus rau hauv cov qauv dendritic, branching tawm hauv ib tsob ntoo zoo li tus qauv. Qhov kawg grain qauv ntawm lubcastingsyog txiav txim siab los ntawm kev loj hlob ntawm cov dendrites thiab lawv cov kev cuam tshuam nrog qhov chaw txias.

Solidification ntawm Ntau yam Alloys

Sib txawv alloys solidify nyob rau hauv tshwj xeeb txoj kev, cuam tshuam los ntawm lawv cov tshuaj muaj pes tsawg leeg thiab thermal zog:

Aluminium Alloys: Aluminium alloys feem ntau pom muaj qib siab ntawm fluidity, tso cai rau kev sib txuam thiab nyias-walled castings. Lawv solidification feem ntau yog tsim los ntawm ib tug nplua, equiaxed grain qauv. Txawm li cas los xij, aluminium alloys yog qhov yooj yim rau shrinkage porosity thiab kub tearing, uas tuaj yeem cuam tshuam qhov zoo ntawm casting.

Hlau thiabHlau Alloys: Cam khwb cia hlau solidifies nrog ib tug complex qauv vim nws cov ntsiab lus carbon siab, tsim graphite flakes los yog nodules. Lub solidification ntawm hlau alloys koom nrog tsim austenite dendrites, uas hloov mus rau hauv ferrite thiab pearlite thaum txias. Cov cua txias thiab cov alloy muaj pes tsawg leeg cuam tshuam rau cov qauv nplej thiab cov khoom siv ntawm cov casting.

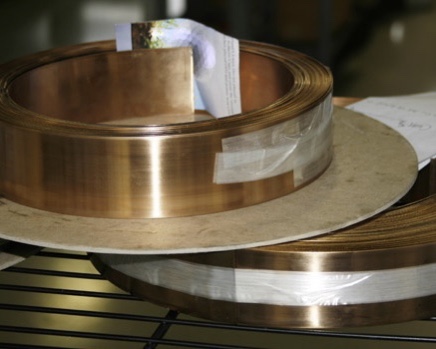

Tooj Alloys: Copper alloys, xws li tooj dag thiab bronze, solidify nrog ib tug columnar los yog equiaxed grain qauv. Cov alloys no nquag sib cais, qhov twg cov ntsiab lus sib txawv hauv cov hlau sib cais thaum lub sij hawm solidification, ua rau muaj kev sib txawv ntawm cov khoom thiab cov khoom hauv qhov casting.

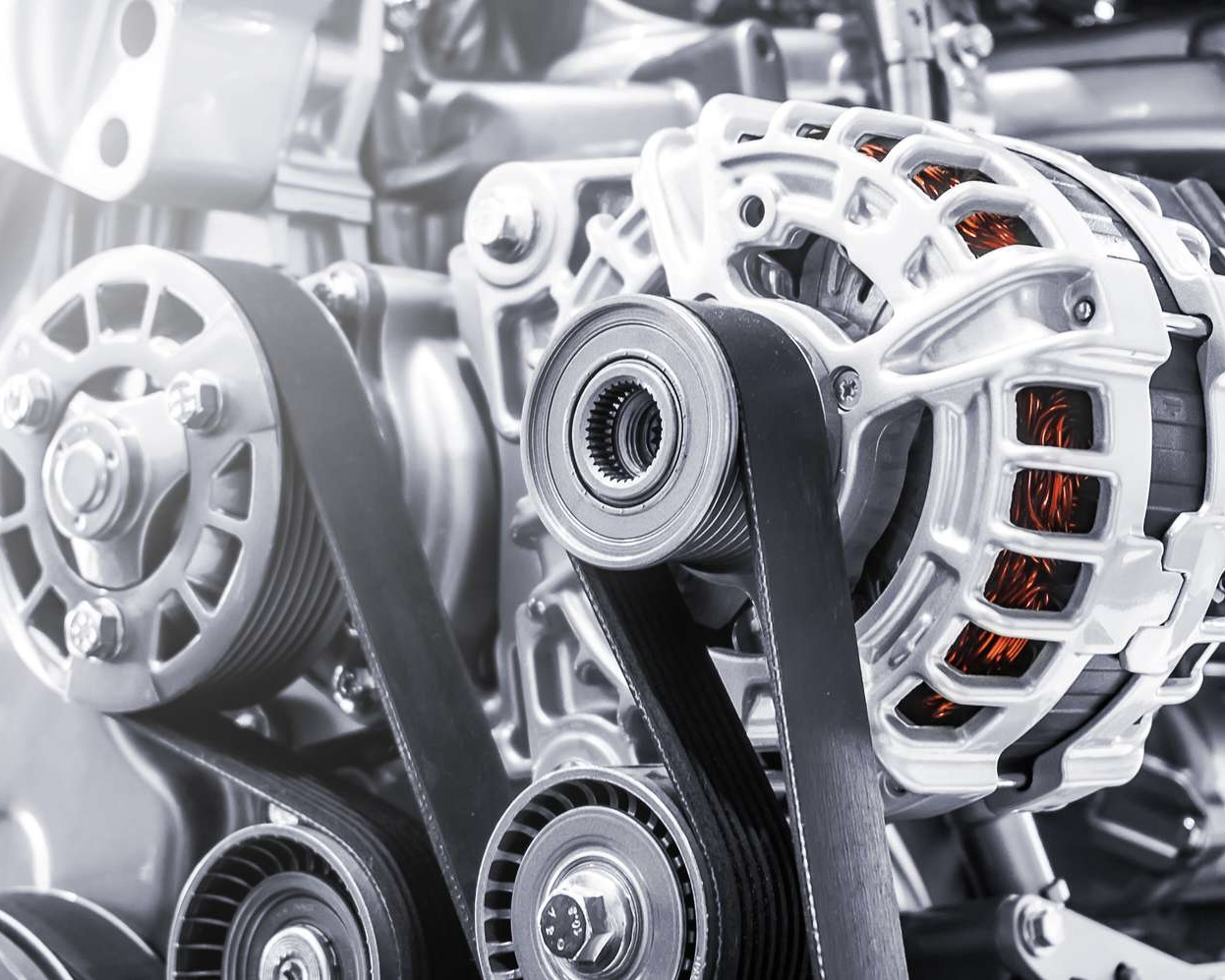

Kev sib raug zoo ntawm Solidification thiab Casting Quality

Tus cwj pwm solidification ntawm ib qho alloy ncaj qha cuam tshuam qhov zoo ntawm cov casting. Cov txheej txheem sib xyaw ua ke thiab kev tswj hwm kev sib koom ua ke yog qhov tseem ceeb los txo qhov tsis xws luag xws li porosity, cais, thiab kub tearing. Piv txwv li, kev ua kom txias ceev tuaj yeem ua rau tsim cov nplej nplua nuj, txhim kho cov khoom siv hluav taws xob ntawm cov casting. Hloov pauv, qeeb qeeb yuav ua rau cov nplej ntxhib thiab ua rau muaj kev cuam tshuam ntau ntxiv.

Solidification Sijhawm thiab Ceev

Lub sij hawm solidification thiab ceev yog cuam tshuam los ntawm tej yam xws li casting qhov loj, zoo, thiab thermal zog ntawm cov khoom pwm. Lub sij hawm solidification yog lub sij hawm yuav tsum tau rau tag nrho cov casting mus hloov los ntawm cov kua rau cov khoom, thaum lub solidification ceev yog hais txog tus nqi ntawm qhov kev hloov no tshwm sim.

Faster solidification speeds yog feem ntau ua tiav los ntawm cov tswv yim xws li kev siv chill pwm, uas sai sai tshem tawm cov cua sov los ntawm cov hlau molten. Qhov no ua rau cov qauv zoo dua qub thiab txhim kho cov khoom siv kho tshuab. Txawm li cas los xij, kev txias txias heev tuaj yeem ua rau thermal stresses thiab tawg. Yog li ntawd, ua tiav qhov kev pom zoo ntawm qhov sib npaug ntawm kev sib tw ceev thiab kev ua haujlwm zoo yog qhov tseem ceeb heev.

Post lub sij hawm: Oct-11-2024