Shrinkage hauv castings yog ib qho tseem ceeb heev uas cuam tshuam qhov zoo thiab kev ncaj ncees ntawm cov khoom kawg. Nkag siab txog ntau hom shrinkage txuam nrog ntau yam ntaub ntawv, xws li hlau nrumthiabnrum hlau, nrog rau cov yam uas ua rau muaj qhov tsis xws luag xws li shrinkage kab noj hniav thiab kub tawg, yog qhov tseem ceeb rau kev coj ua zoo casting.

Shrinkage nyob rau hauv Cam khwb cia hlau thiab cam khwb cia hlau

Thaum tham txog shrinkage, nws yog ib qho tseem ceeb rau kev sib txawv ntawm ob lub ntsiab khoom siv hauv casting:hlau nrumthiabnrum hlau. Ob leeg cov ntaub ntawv nthuav tawm shrinkage, tab sis cov txheej txheem thiab cov nqi sib txawv.

Cam khwb cia hlau feem ntau ntsib ib tug tag nrho shrinkage ntawm kwv yees li1.5% mus rau 2%los ntawm nws lub xeev molten mus rau nws daim ntawv solidified. Qhov no shrinkage feem ntau yog vim thermal contraction ntawm cov khoom thaum nws txias. Nyob rau hauv sib piv, cam khwb cia hlau muaj ib tug ntau dua shrinkage tus nqi, feem ntau nyob ib ncig ntawm2% mus rau 3%. Qhov ntxiv shrinkage nyob rau hauv cam khwb cia hlau tuaj yeem raug ntaus nqi rau nws cov muaj pes tsawg leeg, uas suav nrog cov ntsiab lus carbon ntau dua uas cuam tshuam rau nws tus cwj pwm solidification.

Qhov tseeb Shrinkage ntawm Castings

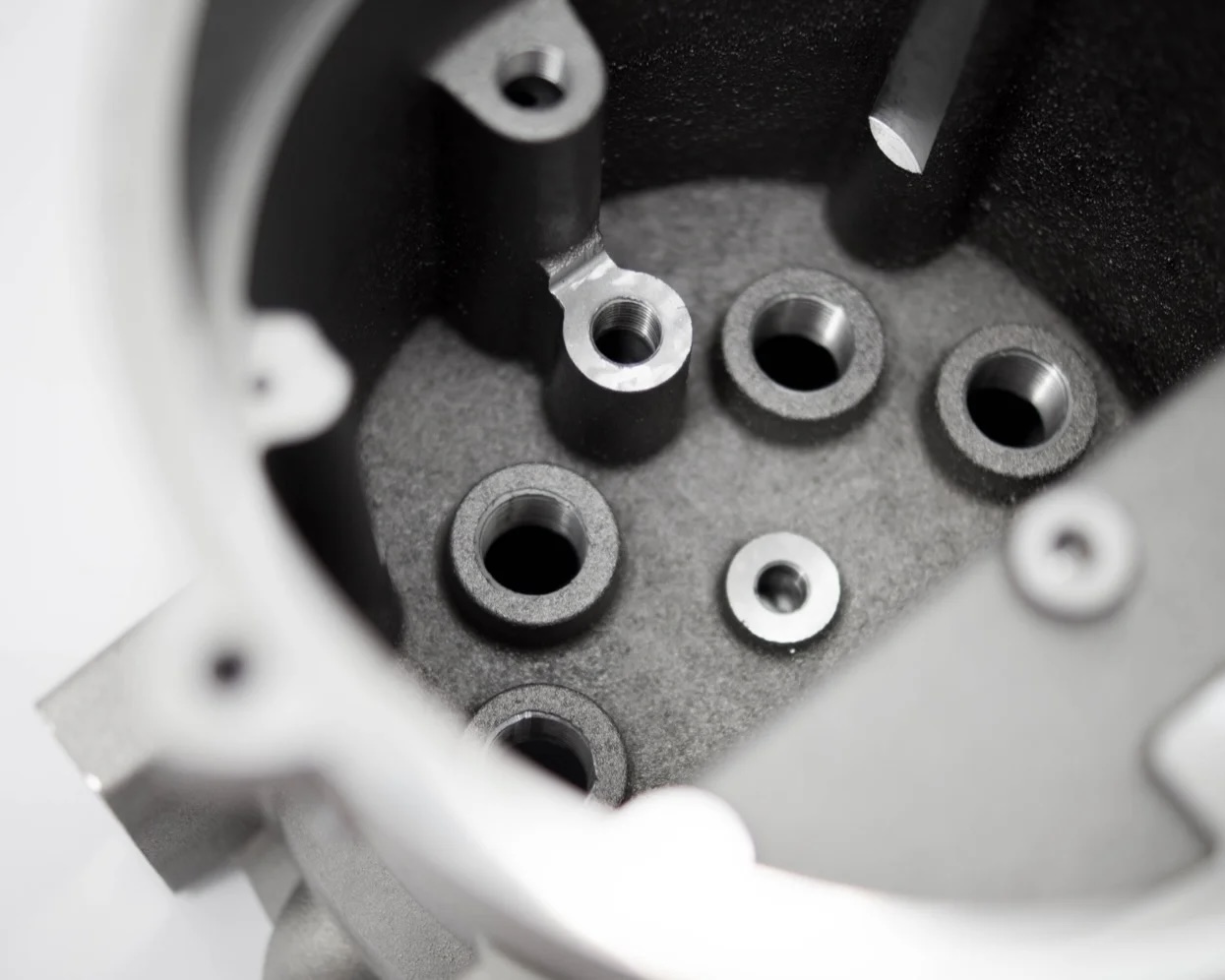

Qhov tseeb shrinkage yog hais txog tag nrho qhov kev hloov pauv uas tau ntsib los ntawm kev ua haujlwm los ntawm nws cov kua hauv lub xeev mus rau nws lub xeev cov khoom kawg. Qhov no tuaj yeem suav nrog ob qho tib si volumetric shrinkage thaum lub caij txias thiab cov teebmeem ntawm solidification. Tsim kom raug thiab xam cov geometry casting yog qhov tseem ceeb kom haum raws li qhov shrinkage no, vim tias tsis ua li ntawd tuaj yeem ua rau muaj qhov tsis raug thiab cuam tshuam cov khoom siv kho tshuab.

Shrinkage Cavities thiab Porosity

Shrinkage kab noj hniav, tseem hu ua shrinkage voids, tshwm sim thaum cov kua hlau tsis ua rau pwm vim tsis txaus noj thaum lub sij hawm solidification. Qhov tshwm sim no tuaj yeem ua rau cov ntsiab lus tsis muaj zog hauv qhov casting, ua rau nws raug rau qhov tsis ua hauj lwm hauv kev thauj khoom. Ntawm qhov tod tes, porosity-feem ntau pom nyob rau hauv castings-yog feem ntau tshwm sim los ntawm gas entrapment los yog cov txheej txheem pouring tsis tsim nyog, uas yuav ua rau kom txo tau tus txheej txheem ntawm kev ncaj ncees.

Kub Cracking thiab Casting Stresses

Kub tawg yog lwm qhov kev txhawj xeeb tseem ceeb hauv casting. Cov no tshwm sim thaum lub casting tseem nyob ntawm qhov kub siab tab sis twb tau pib solidify. Cov kev ntxhov siab tshwm sim thaum lub caij txias tuaj yeem tshaj cov khoom siv lub zog tensile, ua rau tawg. Kev tswj tus nqi cua txias thiab nkag siab txog cov khoom siv thermal ntawm cov khoom tuaj yeem pab txo qhov kev pheej hmoo ntawm kub tawg.

Txias Cracking thiab Deformation

Txias cracking tshwm sim tom qab lub casting tau txias rau chav tsev kub thiab feem ntau yog tshwm sim los ntawm residual stresses. Cov kev ntxhov siab no tuaj yeem tshwm sim los ntawm qhov tsis sib xws, uas ua rau muaj qhov sib txawv sib txawv thoob plaws hauv qhov casting. Cov kev ntxhov siab no kuj tuaj yeem ua rau deformation, cuam tshuam rau qhov kawg ntawm cov duab thiab siv tau.

Txhawm rau txo qhov tshwm sim ntawm qhov txias txias thiab deformation, nws yog ib qho tseem ceeb rau kev siv cov txheej txheem txias kom zoo thiab cov txheej txheem kev ntxhov siab thaum lub sij hawm thiab tom qab cov txheej txheem casting.

Post lub sij hawm: Oct-25-2024