Riser tsim yog ib qho tseem ceeb ntawm cov txheej txheem casting, kom ntseeg tau tias castings tsis muaj qhov tsis xws luag xws li shrinkage kab noj hniav thiab porosity. Risers, tseem hu ua feeders, ua raws li reservoir ntawm molten hlau uas pub lub casting li nws solidifies thiab cog lus.

Riser Tsim rau Steel Castings

In steel peev casting, lub hom phiaj tseem ceeb ntawm riser tsim yog los xyuas kom meej txaus noj ntawm molten hlau los them rau volumetric shrinkage thaum lub sij hawm solidification. Hlau nyhav kom muaj cov nqi shrinkage siab, ua kom zoo riser tsim tseem ceeb.

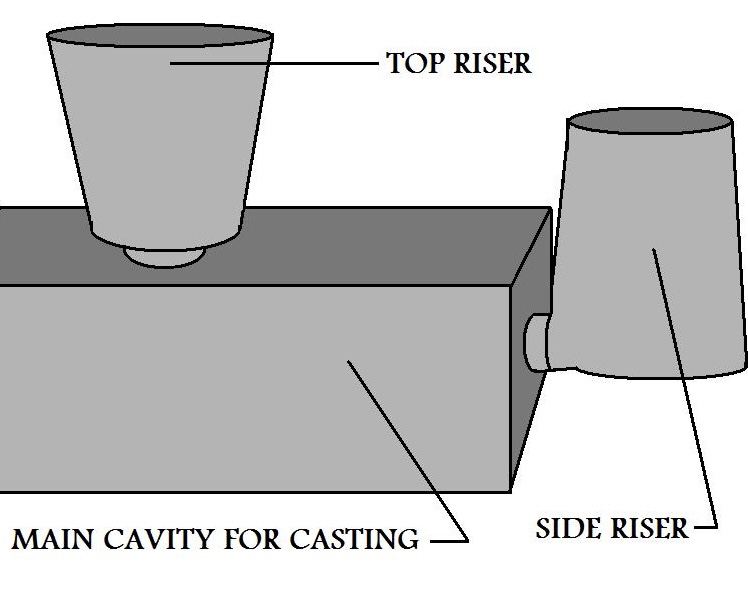

Rau steel castings, ob lub ntsiab ntawm risers yog siv:qhib risers thiabdig muag risers. Qhib risers raug rau qhov chaw, qhov qhov muag tsis pom risers yog nyob rau hauv cov pwm. Qhov muag tsis pom risers muaj txiaj ntsig zoo dua hauv kev txo qis qis.

Risers yuav tsum nyob rau ntawm qhov hnyav tshaj plaws ntawm cov casting qhov twg shrinkage feem ntau tshwm sim. Qhov loj thiab cov duab ntawm cov riser yuav tsum tau tsim los xyuas kom meej lub ntim txaus ntawm cov hlau molten. Cylindrical risers feem ntau yog siv rau lawv qhov yooj yim ntawm kev tshem tawm thiab ua haujlwm zoo hauv kev pub mis. Insulating lub tes tsho thiab cov ntaub ntawv exothermic feem ntau yog siv los tswj qhov kub ntawm lub riser, kom ntseeg tau tias nws tseem molten ntev dua li qhov casting.

Riser Tsim rau Hlau Castings

Rauhlau peev castings, tshwj xeeb tshaj yog grey thiab ductile hlau, lub hom phiaj yog los tswj cov yam ntxwv nthuav dav thaum lub sij hawm solidification. Tsis zoo li cov hlau, qee hom hlau nthuav dav thaum lub sijhawm kawg ntawm kev ua kom muaj zog, txo qhov xav tau rau cov risers loj.

Qhov muag tsis pom risers yog nyiam rau hlau castings vim lawv efficiency. Rau cov hlau nplaum, cov risers me me tuaj yeem ua tau txaus vim tias cov graphite nthuav dav thaum lub zog khov.

Me me, ntau compact risers yuav siv tau rau hlau castings. Cov duab tuaj yeem sib txawv tab sis yuav tsum txo qis qhov chaw ntawm qhov chaw raug tshav kub thaum ua kom cov khoom noj kom zoo. Chills (cov khoom uas nqus cua sov) qee zaum siv nrog cov risers los tswj cov cua txias thiab txhawb kev taw qhia kev sib zog ntawm cov riser.

.jpg)

Riser Design rau Non-ferrousAlloy Castings

Non-ferrous alloys, xws li txhuas thiab tooj liab alloys, muaj cov cwj pwm sib txawv ntawm kev sib txawv piv rau cov hlau ferrous. Lub hom phiaj tseem ceeb yog los tiv thaiv qhov tsis xws luag xws li shrinkage porosity thiab ua kom tiav puv ntawm pwm.

Rau cov uas tsis yog-ferrous castings, ob qho tib si qhib thiab qhov muag tsis pom risers yog siv, nyob ntawm seb cov alloy thiab casting tsim. Qhib risers yog ntau dua rau cov me me castings, thaum qhov muag tsis pom risers yog siv rau loj castings.

Tsis yog-ferrous alloys feem ntau xav kom risers muab tso rau ntawm qhov siab tshaj plaws ntawm cov casting los siv lub ntiajteb txawj nqus.

Cov riser loj yuav tsum suav rau qhov qis dua thiab qis dua tus nqi ntawm cov hlau tsis muaj hlau. Tapered los yog necked risers tuaj yeem pab txo kom tsis txhob muaj cua sov thiab txhim kho kev noj zaub mov zoo. Kev rwb thaiv tsev yog qhov tseem ceeb rau cov hlau tsis muaj hlau, vim lawv feem ntau solidify ntawm qhov kub thiab txias. Exothermic cov ntaub ntawv thiab lub tes tsho insulating tuaj yeem pab tswj lub xeev molten ntawm riser rau lub sijhawm ntev.

Post lub sij hawm: Dec-20-2024