Hnav-resistant (los yog abrasion-resistant) cam khwb cia hlau hais txog cam khwb cia hlau nrog zoo hnav tsis kam. Raws li tshuaj muaj pes tsawg leeg, nws muab faib ua non-alloy, low-alloy thiab alloy hnav-resistant cam khwb cia hlau. Muaj ntau ntau hom kev hnav-tiv taus steel, uas tuaj yeem muab faib ua high-manganese steel, nruab nrab thiab qis alloy hnav-resistant steel, chromium-molybdenum-silicon-manganese steel, cavitation-resistant steel, hnav-resistant steel, thiab tshwj xeeb hnav-resistant steel. Qee cov hlau hlau dav hlau xws li cov hlau tsis muaj steel, cov kabmob hlau, cov cuab yeej hlau hlau thiab cov hlau hlau alloy kuj siv los ua cov hlau tsis muaj zog nyob rau hauv cov xwm txheej tshwj xeeb.

Nruab nrab thiab qis-alloy hnav-resistant steels feem ntau muaj cov khoom siv tshuaj xws li silicon, manganese, chromium, molybdenum, vanadium, tungsten, npib tsib xee, titanium, boron, tooj liab, tsis tshua muaj ntiaj teb, thiab lwm yam. Cov kab ntawm ntau lub pob loj thiab nruab nrab. mills hauv Tebchaws Meskas yog ua los ntawm chromium-molybdenum-silico-manganese lossis chromium-molybdenum hlau. Feem ntau ntawm cov khoom sib tsoo hauv Tebchaws Meskas yog ua los ntawm nruab nrab thiab siab carbon chromium molybdenum steel. Rau workpieces uas ua hauj lwm nyob rau hauv kuj kub (piv txwv li, 200 ~ 500 ℃) abrasive hnav tej yam kev mob los yog nws cov nto yog raug rau kub kub vim kev sib txhuam, alloys xws li chromium molybdenum vanadium, chromium molybdenum vanadium nickel los yog chromium molybdenum vanadium tungs. siv tau.

Kev puas tsuaj yog ib qho tshwm sim uas cov khoom siv ntawm qhov chaw ua haujlwm ntawm ib qho khoom raug puas tsuaj tas li los yog poob hauv kev txheeb ze. Muab faib los ntawm cov txheej txheem hnav, hnav tuaj yeem muab faib ua abrasive hnav, nplaum hnav, hnav corrosion, yaig hnav, tiv tauj hnav hnav, cuam tshuam hnav, fretting hnav thiab lwm yam. Hauv kev lag luam kev lag luam, abrasive hnav thiab adhesive hnav account rau qhov loj tshaj plaws ntawm cov khoom siv ua haujlwm tsis ua haujlwm, thiab hnav tsis ua haujlwm xws li yaig, corrosion, qaug zog, thiab fretting yuav tshwm sim hauv kev ua haujlwm ntawm qee yam tseem ceeb, yog li lawv tau txais ntau dua. thiab ntau xim. Hauv kev ua haujlwm, ntau hom kev hnav feem ntau tshwm sim tib lub sijhawm lossis ib qho tom qab, thiab kev sib cuam tshuam ntawm kev hnav tsis ua haujlwm yuav siv sij hawm ntau dua. Kev txiav txim siab txog hom kev hnav tsis ua haujlwm ntawm lub workpiece yog lub hauv paus rau kev xaiv tsim nyog lossis kev txhim kho ntawm cov hlau tsis muaj zog.

Tsis tas li ntawd, kev hnav ntawm cov khoom thiab cov khoom siv yog qhov teeb meem engineering. Muaj ntau yam cuam tshuam rau kev hnav, nrog rau kev ua haujlwm (load, ceev, txav hom), lubrication tej yam kev mob, ib puag ncig yam (humidity, kub, ib puag ncig xov xwm, thiab lwm yam), thiab cov khoom yam tseem ceeb (Composition, lub koom haum, mechanical zog), nto zoo thiab lub cev thiab tshuaj lom neeg cov khoom ntawm qhov chaw. Kev hloov pauv ntawm txhua yam ntawm cov xwm txheej no tuaj yeem hloov pauv qhov hnav thiab txawm tias hloov pauv qhov hnav khaub ncaws. Nws tuaj yeem pom tias cov khoom tseem ceeb tsuas yog ib qho ntawm cov yam ntxwv uas cuam tshuam rau kev hnav ntawm lub workpiece. Txhawm rau txhim kho qhov hnav tsis kam ntawm cov hlau qhov chaw, nws yog ib qho tsim nyog yuav tsum pib nrog kev sib txhuam tag nrho thiab hnav lub cev nyob rau hauv cov xwm txheej tshwj xeeb kom ua tiav cov txiaj ntsig xav tau.

1. Kev kho cua sov (Dej Toughening Treatment) ntawm Hnav-Resistant High Manganese Steel Castings

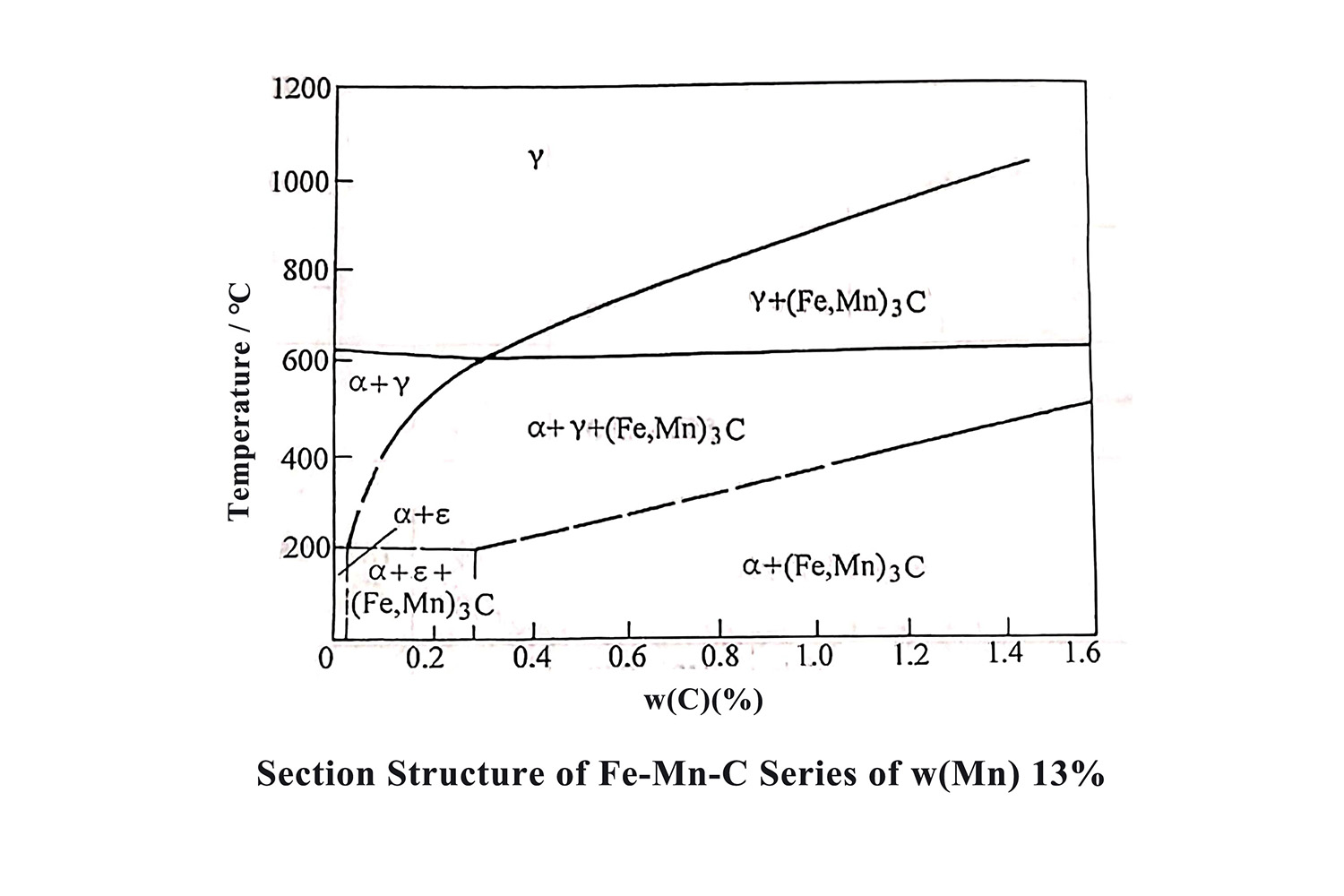

Muaj ntau ntau ntawm precipitated carbides nyob rau hauv lub as-cast qauv ntawm hnav-resistant high-manganese hlau. Cov carbides no yuav txo qhov toughness ntawm cov casting thiab ua kom yooj yim tawg thaum siv. Lub hom phiaj tseem ceeb ntawm kev kho cua sov ntawm high manganese steel castings yog tshem tawm carbides nyob rau hauv lub as-cam qauv thiab nyob rau hauv lub grain ciam teb kom tau ib tug ib-theem austenite qauv. Qhov no tuaj yeem txhim kho lub zog thiab toughness ntawm siab manganese steel, kom siab manganese steel castings tsim nyog rau ntau thaj chaw.

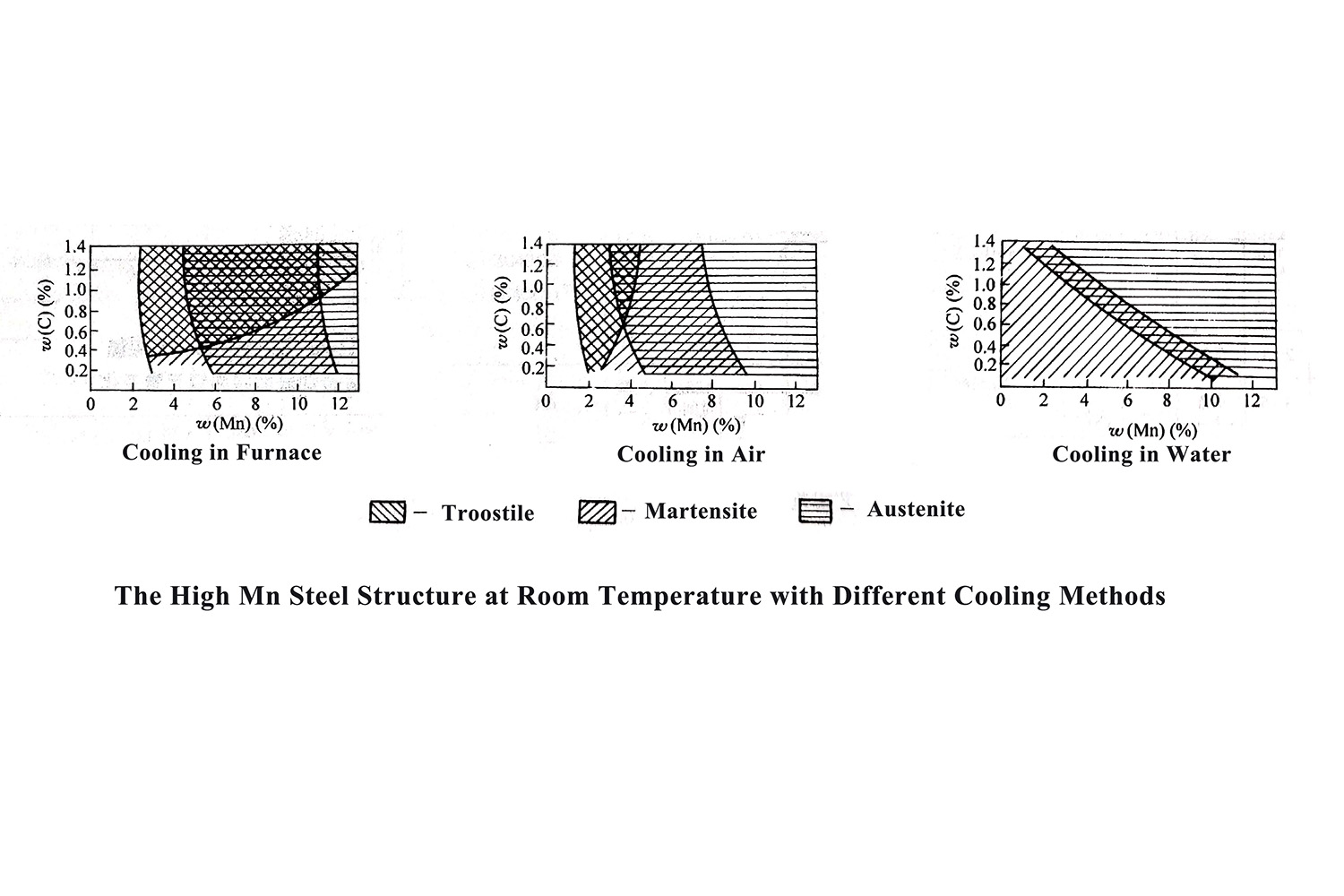

Kev kho cua sov ntawm kev hnav-resistant high-manganese steel castings tuaj yeem faib ua ob peb kauj ruam: ua kom sov cov castings siab tshaj 1040 ° C thiab tuav lawv rau lub sijhawm tsim nyog, kom cov carbides nyob rau hauv tag nrho yaj nyob rau hauv ib-theem austenite. ; ces txias txias, Tau austenite khoom tov qauv. Qhov kev daws teeb meem no tseem hu ua kev kho dej toughening.

(1) Kev ntsuas kub ntawm cov dej toughening

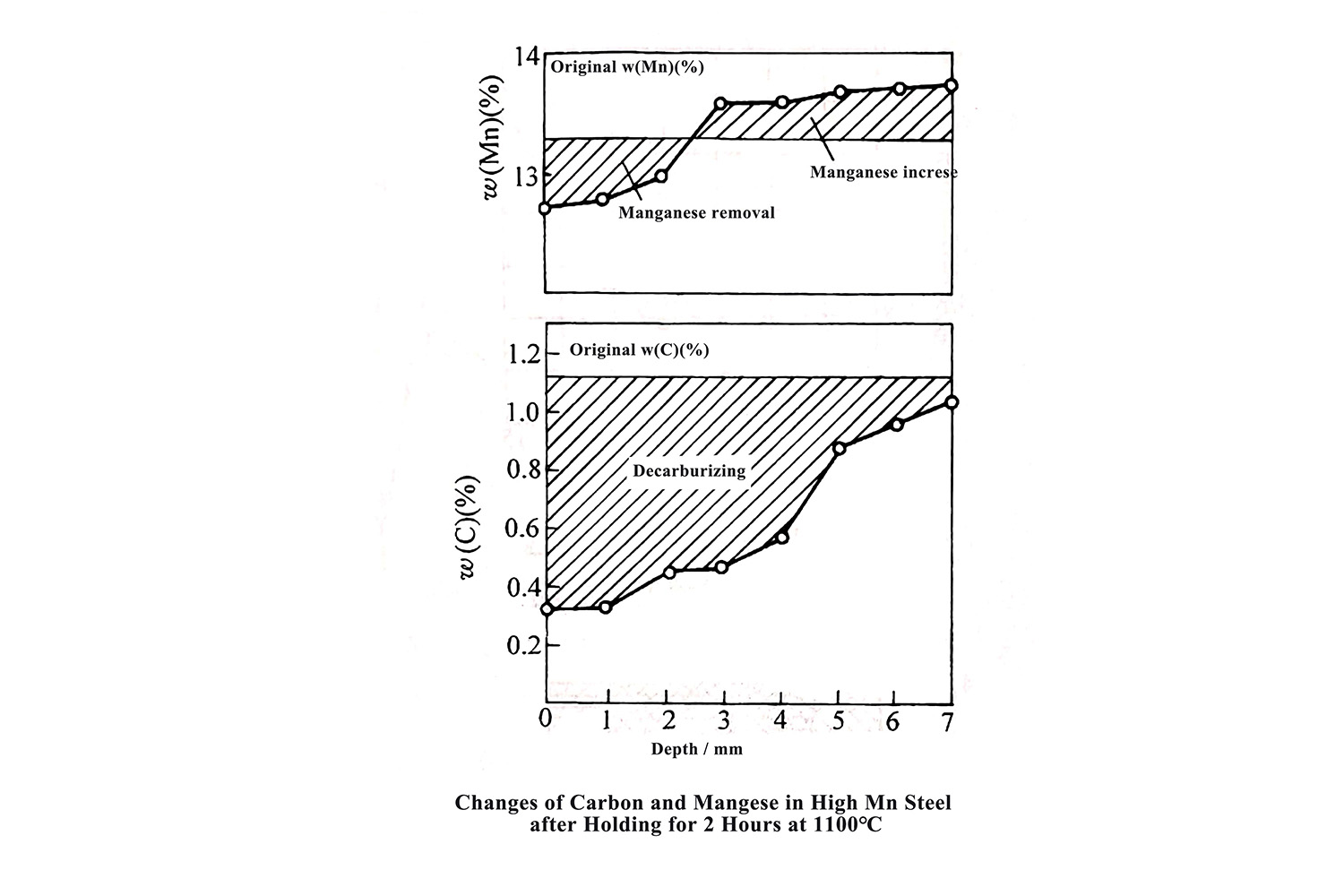

Cov dej toughness kub nyob ntawm cov tshuaj muaj pes tsawg leeg ntawm cov hlau manganese siab, feem ntau 1050 ℃ -1100 ℃. High manganese steels nrog cov ntsiab lus carbon siab lossis cov ntsiab lus alloy siab (xws li ZG120Mn13Cr2 steel thiab ZG120Mn17 steel) yuav tsum siv qhov siab tshaj ntawm cov dej toughness kub. Txawm li cas los xij, qhov kub thiab txias heev ntawm cov dej yuav ua rau decarburization hnyav rau ntawm qhov chaw ntawm qhov casting thiab kev loj hlob sai ntawm high manganese steel nplej, uas yuav cuam tshuam rau kev ua haujlwm ntawm cov hlau manganese siab.

(2) Kev kho cua sov ntawm cov dej toughening

Lub thermal conductivity ntawm manganese hlau yog phem dua li ntawm cov pa roj carbon steel. High-manganese steel castings muaj kev ntxhov siab thiab yooj yim tawg thaum rhuab, yog li cov cua sov yuav tsum tau txiav txim siab raws li phab ntsa thickness thiab cov duab ntawm cov casting. Feem ntau hais lus, castings nrog cov phab ntsa me me thiab cov qauv yooj yim tuaj yeem ua kom sov ntawm tus nqi nrawm dua; castings nrog loj phab ntsa thickness thiab complex qauv yuav tsum tau rhuab maj mam. Nyob rau hauv cov txheej txheem kev kho cua sov tiag tiag, txhawm rau txo qhov deformation lossis tawg ntawm cov casting thaum lub sij hawm cua sov txheej txheem, nws yog feem ntau rhuab mus txog 650 ℃ kom qhov kub ntawm qhov sib txawv ntawm sab hauv thiab sab nraud ntawm lub casting txo, thiab qhov kub thiab txias nyob rau hauv. lub cub tawg yog uniform, thiab sai sai nce mus rau cov dej toughness kub.

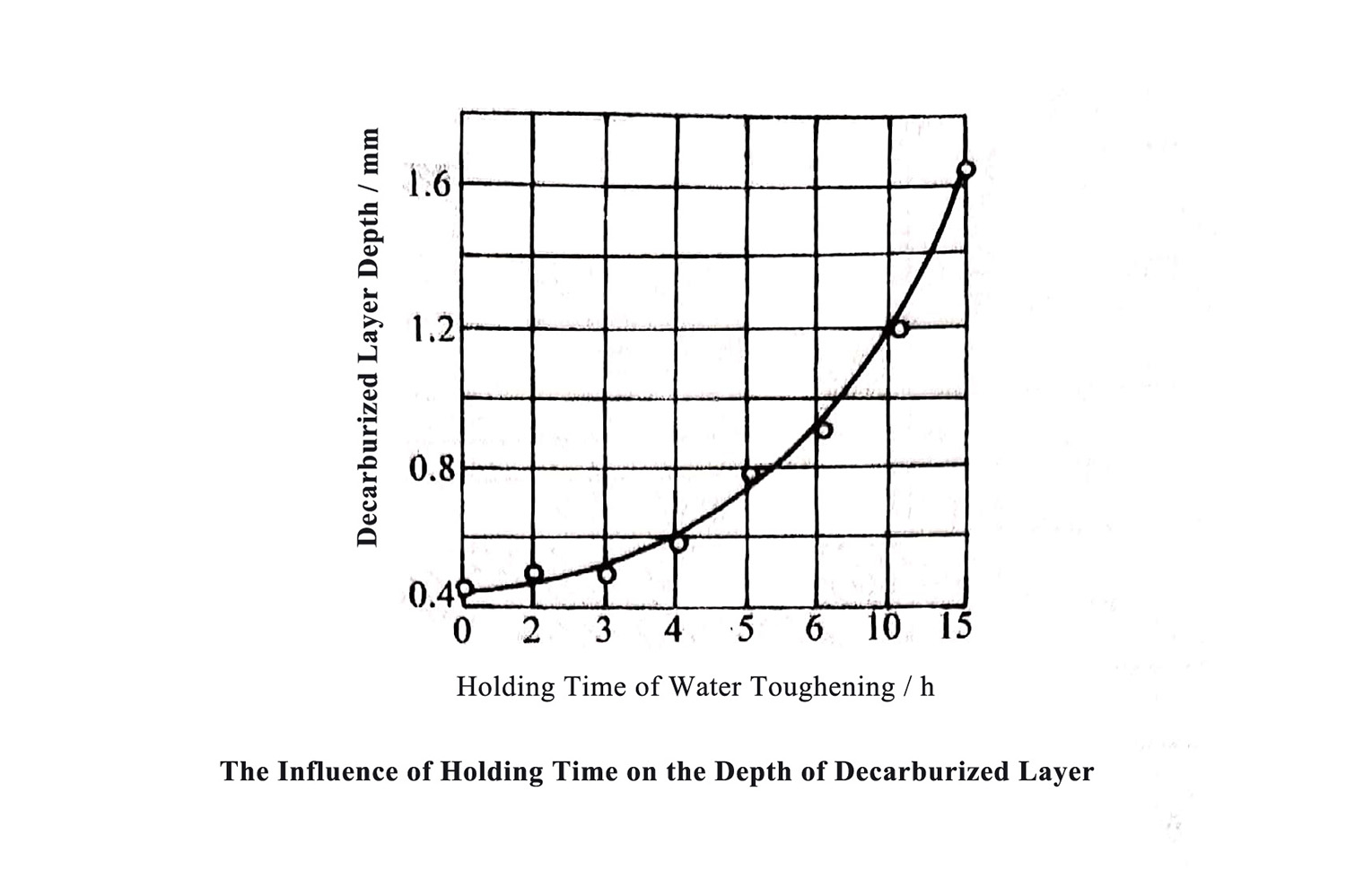

(3) Tuav lub sij hawm ntawm kev kho dej toughening

Lub sij hawm tuav dej toughening kev kho feem ntau yog nyob ntawm phab ntsa thickness ntawm lub casting, thiaj li yuav xyuas kom meej lub tiav dissolution ntawm carbides nyob rau hauv lub as-cast qauv thiab homogenization ntawm lub austenite qauv. Raws li ib txwm muaj, nws tuaj yeem suav tau los ntawm kev nce lub sijhawm tuav los ntawm 1 teev rau txhua 25 hli nce ntawm phab ntsa tuab.

(4) Kev kho cua txias ntawm dej toughening

Cov txheej txheem cua txias muaj kev cuam tshuam zoo rau kev ua haujlwm Performance index thiab cov qauv ntawm cov casting. Thaum lub sij hawm kev kho dej toughening, qhov kub ntawm casting ua ntej nkag mus rau hauv dej yuav tsum siab tshaj 950 ° C los tiv thaiv carbides los ntawm re-precipitating. Vim li no, lub sijhawm luv ntawm kev tawm ntawm lub qhov cub thiab nkag mus rau hauv dej yuav tsum tsis pub tshaj 30 vib nas this. Cov dej kub yuav tsum qis dua 30 ° C ua ntej lub casting nkag mus rau hauv dej, thiab qhov siab tshaj plaws dej kub tom qab nkag mus rau hauv dej yuav tsum tsis txhob ntau tshaj 50 ° C.

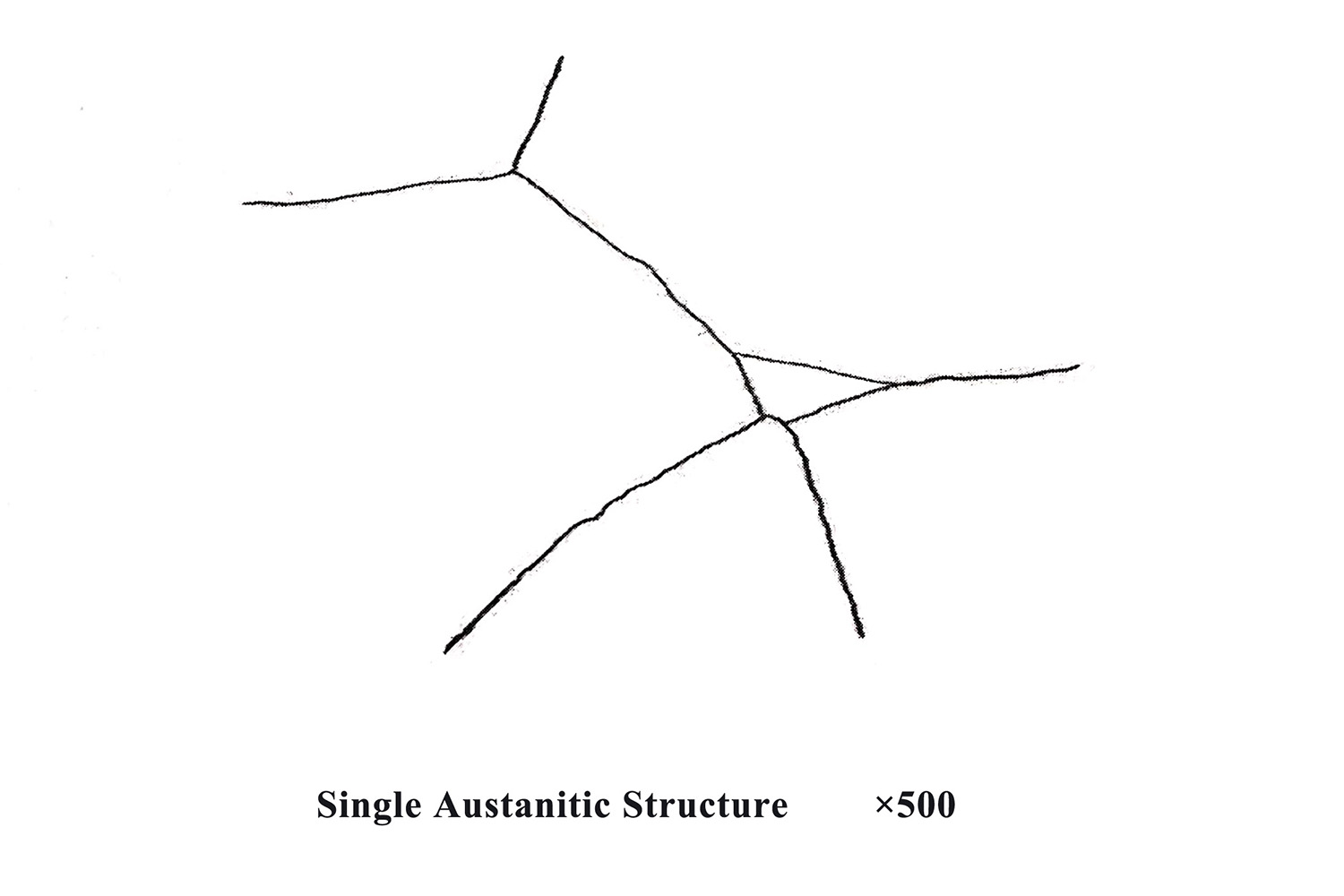

(5) Carbide tom qab kev kho dej toughening

Tom qab cov dej toughening kev kho mob, yog hais tias cov carbides nyob rau hauv siab manganese hlau yog kiag li tshem tawm, lub metallographic qauv tau txais nyob rau hauv lub sij hawm no yog ib tug austenite qauv. Tab sis xws li ib tug qauv tsuas yog tau nyob rau hauv nyias-walled castings. Feem ntau, ib qho me me ntawm carbides nyob rau hauv cov nplej austenite los yog nyob rau hauv cov qoob loo ciam teb. Undissolved carbides thiab precipitated carbides tuaj yeem raug tshem tawm los ntawm kev kho cua sov dua. Txawm li cas los xij, eutectic carbides precipitated vim cua sov ntau dhau thaum lub sij hawm kho dej toughening tsis tau. Vim tias eutectic carbide tsis tuaj yeem tshem tawm los ntawm kev kho cua sov dua.

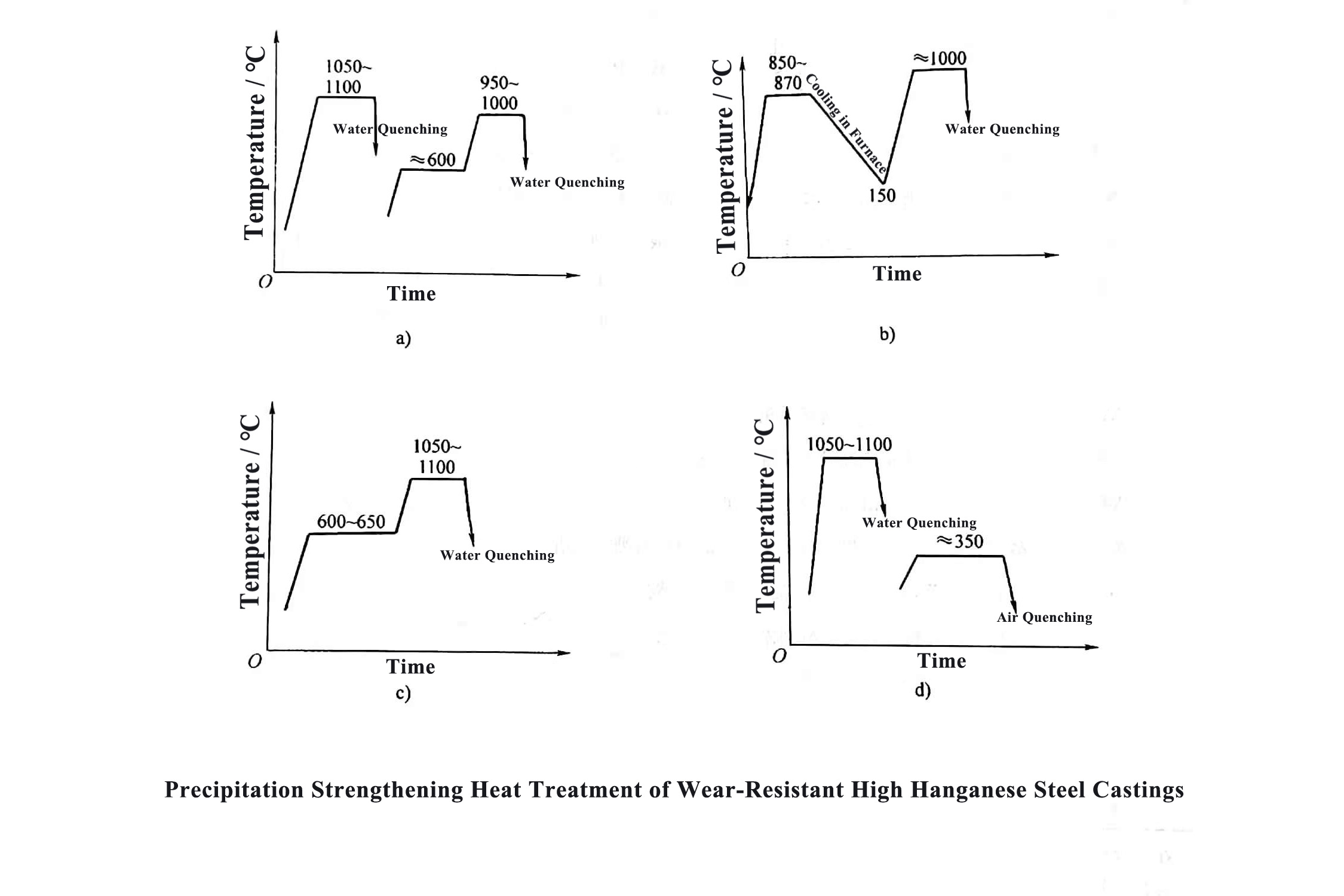

2. Los nag los tiv thaiv tshav kub kho ntawm hnav-Resistant High Hanganese Steel Castings

Kev kho cua sov ua kom muaj zog ntawm kev hnav-tiv taus siab manganese hlau hais txog qhov sib ntxiv ntawm qee yam ntawm cov carbide tsim cov ntsiab lus (xws li molybdenum, tungsten, vanadium, titanium, niobium thiab chromium) los ntawm kev kho cua sov kom tau txais qee qhov nyiaj thiab loj hauv siab manganese hlau Qhov thib ob theem ntawm dispersed carbide hais. Qhov kev kho cua sov no tuaj yeem ntxiv dag zog rau austenite matrix thiab txhim kho qhov hnav tsis kam ntawm siab manganese hlau.

3. Kev kho cua sov ntawm Hnav-resistant Medium Chromium Steel Castings

Lub hom phiaj ntawm kev kho cua sov ntawm kev hnav-resistant nruab nrab chromium steel castings yog kom tau txais cov qauv martensite matrix nrog lub zog siab, toughness thiab siab hardness, thiaj li los txhim kho lub zog, toughness thiab hnav tsis kam ntawm steel castings.

Hnav-resistant nruab nrab chromium steel muaj ntau chromium ntsiab thiab muaj zog dua hardenability. Yog li ntawd, nws txoj kev kho cua sov li niaj zaus yog: tom qab 950 ℃ - 1000 ℃, nws cov austenitization, tom qab ntawd quenching kev kho mob, thiab kev kho mob raws sij hawm (feem ntau ntawm 200-300 ℃).

4. Kev kho cua sov ntawm Hnav-Resistant Low-Alloy Steel Castings

Wear-resistant low-alloy steel castings yog kho los ntawm quenching hauv dej, quenching hauv roj thiab cua quenching nyob ntawm cov alloy muaj pes tsawg leeg thiab cov ntsiab lus carbon. Pearlitic hnav-resistant cam khwb cia hlau txais yuav normalizing + tempering kub kho.

Txhawm rau kom tau txais martensite matrix nrog lub zog siab, toughness thiab hardness, thiab txhim kho qhov hnav tsis kam ntawm steel castings, hnav-resistant low-alloy steel castings feem ntau quenched ntawm 850-950 ° C thiab tempered ntawm 200-300 ° C. .

Post lub sij hawm: Aug-07-2021