Kev kho cua sov ntawm cov hlau castings yog raws li Fe-Fe3C daim duab kos los tswj cov microstructure ntawm cov hlau castings kom ua tiav qhov kev ua tau zoo. Kev kho cua sov yog ib qho ntawm cov txheej txheem tseem ceeb hauv kev tsim cov hlau castings. Qhov zoo thiab cov nyhuv ntawm kev kho cua sov yog ncaj qha ntsig txog qhov kawg kev ua tau zoo ntawm steel castings.

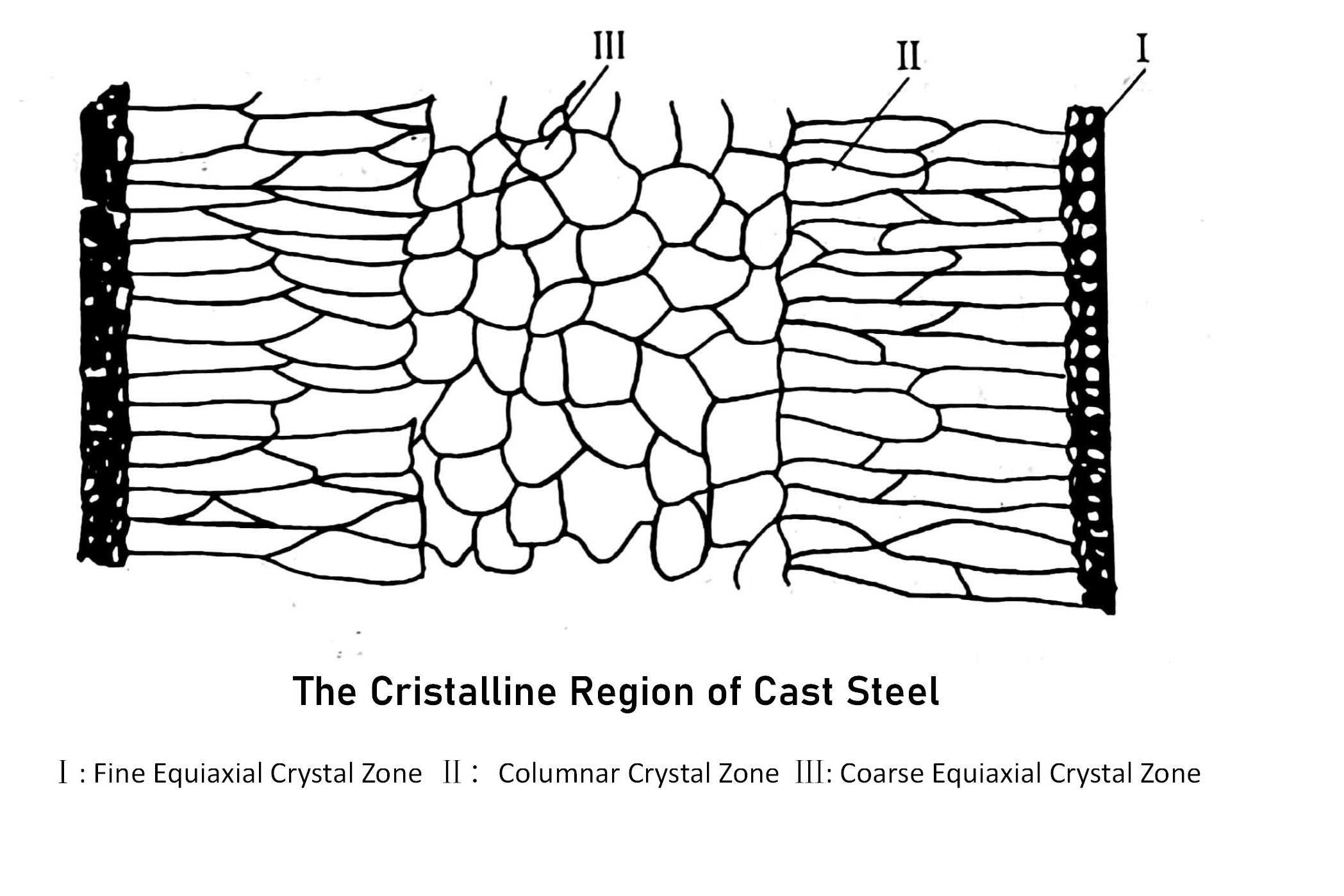

Raws li-cast qauv ntawm steel castings nyob ntawm cov tshuaj muaj pes tsawg leeg thiab solidification txheej txheem. Feem ntau, muaj cov dendrite sib cais loj heev, cov qauv tsis sib xws thiab cov nplej ntxhib. Yog li, steel castings feem ntau yuav tsum tau kho cua sov kom tshem tawm lossis txo qhov cuam tshuam ntawm cov teeb meem saum toj no, txhawm rau txhim kho cov khoom siv ntawm cov hlau castings. Tsis tas li ntawd, vim qhov sib txawv ntawm cov qauv thiab phab ntsa tuab ntawm cov hlau castings, ntau qhov chaw ntawm tib lub casting muaj ntau hom kev koom tes thiab tsim kom muaj kev ntxhov siab ntau ntxiv. Yog li ntawd, steel castings (tshwj xeeb tshaj yog alloy steel castings) feem ntau yuav tsum tau xa nyob rau hauv lub tshav kub-kho lub xeev.

1. Cov yam ntxwv ntawm kev kho cua sov ntawm cov hlau Castings

1) Nyob rau hauv lub as-cam qauv ntawm steel castings, feem ntau coarse dendrites thiab segregation. Thaum lub sij hawm kho cua sov, lub sij hawm cua sov yuav tsum yog me ntsis siab dua li ntawm forging steel qhov chaw ntawm tib yam muaj pes tsawg leeg. Nyob rau tib lub sijhawm, lub sijhawm tuav ntawm austenitization yuav tsum tau txuas ntxiv kom tsim nyog.

2) Vim muaj kev sib cais loj ntawm cov qauv ua-cam khwb cia ntawm qee cov hlau hlau castings, txhawm rau tshem tawm nws cov cawv ntawm cov khoom kawg ntawm cov castings, kev ntsuas yuav tsum tau coj mus rau homogenize thaum kho cua sov.

3) Rau steel castings nrog complex duab thiab loj phab ntsa thickness sib txawv, cross-sectional cuam tshuam thiab casting kev ntxhov siab yuav tsum tau txiav txim siab thaum kho cua sov.

4) Thaum kev kho cua sov ua tiav ntawm cov hlau castings, nws yuav tsum tsim nyog raws li nws cov yam ntxwv ntawm cov qauv thiab sim kom tsis txhob deformation ntawm cov castings.

2. Cov txheej txheem tseem ceeb ntawm kev kho cua sov ntawm cov hlau Castings

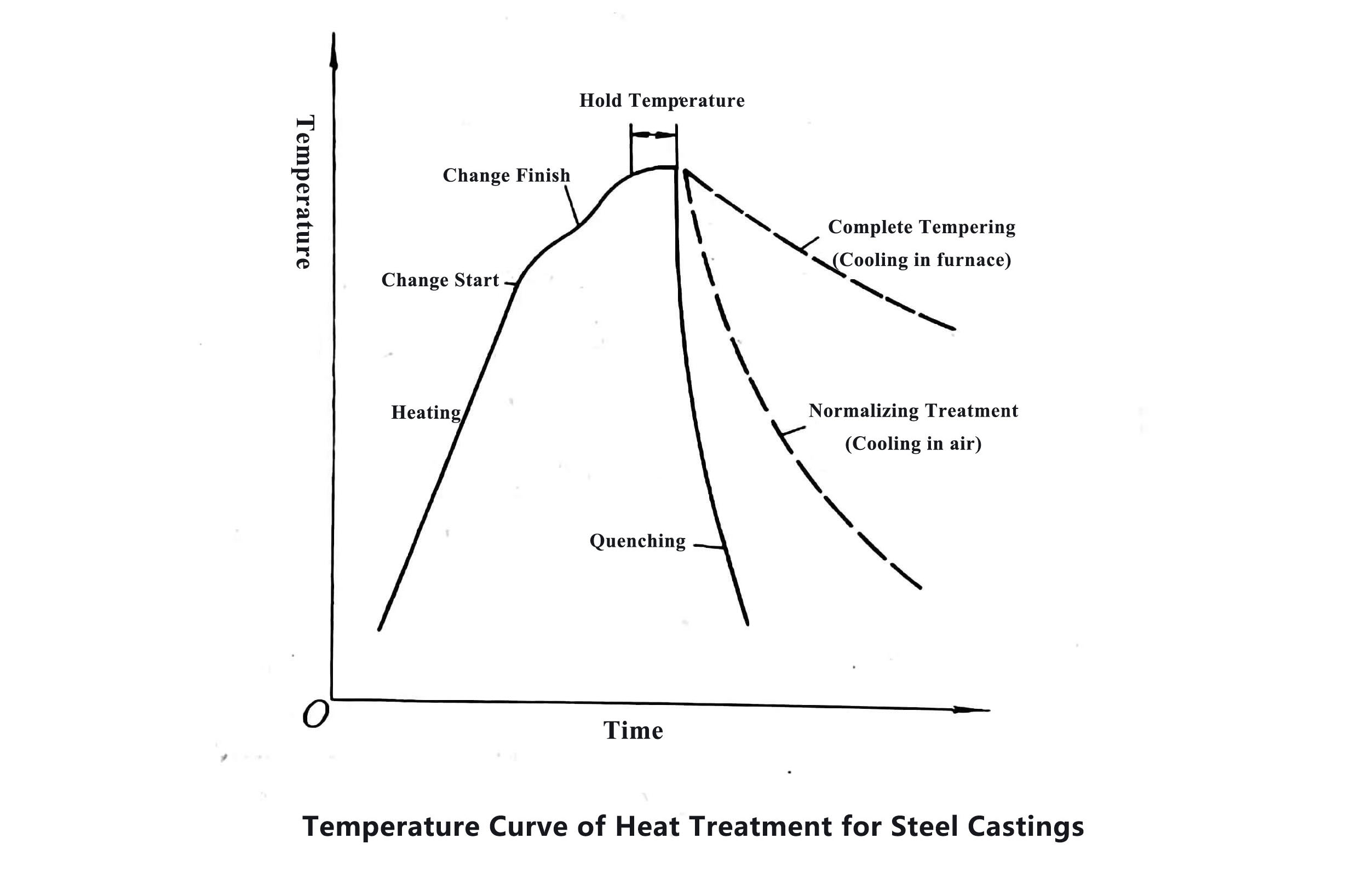

Kev kho cua sov ntawm steel castings muaj peb theem: cua sov, txuag hluav taws xob, thiab cua txias. Kev txiav txim siab ntawm cov txheej txheem yuav tsum tau ua raws li lub hom phiaj ntawm kev ua kom cov khoom zoo thiab txuag nqi.

1) Cua sov

Cov cua sov yog cov txheej txheem siv hluav taws xob ntau tshaj plaws hauv cov txheej txheem kho cua sov. Cov txheej txheem tseem ceeb ntawm cov txheej txheem cua sov yog xaiv cov txheej txheem cua sov uas tsim nyog, cua kub ceev thiab kev them nyiaj.

(1) Cov txheej txheem cua sov. Cov txheej txheem cua sov ntawm cov hlau castings feem ntau muaj xws li radiant cua sov, ntsev da dej cua sov thiab induction cua sov. Lub hauv paus ntsiab lus ntawm kev xaiv cov cua sov yog ceev thiab zoo ib yam, yooj yim los tswj, high efficiency thiab tsawg tus nqi. Thaum cua sov, lub foundry feem ntau txiav txim siab qhov loj ntawm cov qauv, tshuaj muaj pes tsawg leeg, txheej txheem kev kho cua sov thiab cov kev xav tau zoo ntawm cov casting.

(2) Cua kub ceev. Rau cov hlau castings dav dav, cov cua kub ceev yuav tsis txwv, thiab lub zog siab tshaj plaws ntawm lub cub tawg yog siv rau cua sov. Kev siv lub cub tawg kub tuaj yeem txo lub sijhawm cua sov thiab lub voj voog ntau lawm. Qhov tseeb, nyob rau hauv cov xwm txheej ntawm cov cua kub ceev, tsis muaj qhov pom tseeb qhov kub thiab txias hysteresis ntawm qhov chaw ntawm qhov casting thiab cov tub ntxhais. Cov cua sov qeeb yuav ua rau txo qis kev ua haujlwm, kev siv hluav taws xob ntau ntxiv, thiab oxidation loj thiab decarburization ntawm qhov chaw casting. Txawm li cas los xij, rau qee qhov castings nrog cov duab thiab cov qauv, cov phab ntsa loj, thiab cov thermal stresses loj thaum lub sij hawm cua sov, cov cua kub ceev yuav tsum tau tswj. Feem ntau, tsis tshua muaj kub thiab cua sov qeeb (qis dua 600 ° C) los yog nyob ntawm qhov kub qis lossis nruab nrab tuaj yeem siv tau, thiab tom qab ntawd cov cua kub ceev tuaj yeem siv rau hauv qhov kub thiab txias.

(3) Txoj kev thauj khoom. Lub hauv paus ntsiab lus uas cov hlau castings yuav tsum tau muab tso rau hauv lub cub tawg yog siv tag nrho ntawm qhov chaw zoo, xyuas kom muaj cua sov tsis sib xws thiab tso cov castings kom deform.

2) rwb thaiv tsev

Kev tuav kub rau austenitization ntawm steel castings yuav tsum tau xaiv raws li cov tshuaj muaj pes tsawg leeg ntawm cov cam khwb cia hlau thiab cov khoom yuav tsum tau. Qhov tuav kub yog feem ntau me ntsis siab dua (kwv yees li 20 ° C) dua li forging steel qhov chaw ntawm tib yam muaj pes tsawg leeg. Rau eutectoid steel castings, nws yuav tsum tau ua kom ntseeg tau tias carbides tuaj yeem muab tso rau hauv austenite sai, thiab cov austenite tuaj yeem tswj tau cov nplej zoo.

Ob yam yuav tsum tau txiav txim siab rau lub sij hawm txuag hluav taws xob ntawm cov hlau castings: thawj qhov tseem ceeb yog ua kom qhov kub thiab txias ntawm qhov chaw casting thiab cov tub ntxhais sib xws, thiab qhov thib ob yog los xyuas kom meej qhov sib xws ntawm cov qauv. Yog li ntawd, lub sij hawm tuav feem ntau yog nyob ntawm thermal conductivity ntawm lub casting, phab ntsa thickness ntawm seem thiab alloy ntsiab. Feem ntau hais lus, alloy steel castings yuav tsum tau tuav lub sijhawm ntev dua li carbon steel castings. Phab ntsa tuab ntawm cov casting feem ntau yog lub hauv paus tseem ceeb rau kev suav lub sijhawm tuav. Rau lub sijhawm tuav ntawm tempering kev kho mob thiab kev laus kev kho mob, yam xws li lub hom phiaj ntawm kev kho cua sov, tuav kub thiab lub ntsiab diffusion tus nqi yuav tsum xav txog.

3) Cua txias

Cov hlau castings tuaj yeem ua kom txias ntawm qhov sib txawv ntawm qhov nrawm tom qab kev txuag hluav taws xob, txhawm rau ua kom tiav cov kev hloov pauv ntawm metallographic, tau txais cov qauv metallographic uas yuav tsum tau ua thiab ua tiav cov ntsuas kev ua tau zoo. Feem ntau hais lus, nce tus nqi cua txias tuaj yeem pab kom tau txais cov qauv zoo thiab ua kom zoo dua cov nplej, yog li kev txhim kho cov khoom siv ntawm cov casting. Txawm li cas los xij, yog tias qhov ntsuas cua txias nrawm dhau, nws yooj yim ua rau muaj kev ntxhov siab ntau dua hauv cov casting. Qhov no yuav ua rau deformation los yog tawg ntawm castings nrog complex qauv.

Cov cua txias nruab nrab rau kev kho cua sov ntawm steel castings feem ntau muaj xws li cua, roj, dej, dej ntsev thiab molten ntsev.

3. Txoj kev kho cua sov ntawm cov hlau Castings

Raws li cov txheej txheem cua sov sib txawv, tuav lub sijhawm thiab txias txias, cov txheej txheem kev kho cua sov ntawm cov hlau castings feem ntau suav nrog annealing, normalizing, quenching, tempering, kev daws teeb meem, nag lossis daus hardening, kev kho kev ntxhov siab thiab kev kho hydrogen tshem tawm.

1) Annealing.

Annealing yog kom sov cov hlau uas nws cov qauv deviates los ntawm qhov sib npaug ntawm lub xeev mus rau ib tug tej yam kub predetermined los ntawm tus txheej txheem, thiab ces maj mam txias nws tom qab tshav kub preservation (feem ntau yog txias nrog lub cub tawg los yog faus rau hauv txiv qaub) kom tau ib tug kev kho cua sov txheej txheem nyob ze ntawm lub equilibrium lub xeev ntawm cov qauv. Raws li qhov muaj pes tsawg leeg ntawm cov hlau thiab lub hom phiaj thiab cov kev xav tau ntawm annealing, annealing tuaj yeem muab faib ua tiav annealing, isothermal annealing, spheroidizing annealing, recrystallization annealing, kev nyuaj siab annealing thiab lwm yam.

(1) Ua kom tiav Annealing. Cov txheej txheem dav dav ntawm kev ua kom tiav yog: cua sov cov hlau casting rau 20 ° C-30 ° C saum toj no Ac3, tuav nws rau lub sijhawm, kom cov qauv hauv cov hlau hloov pauv mus rau hauv austenite, thiab tom qab ntawd maj mam txias (feem ntau. txias nrog lub cub tawg) ntawm 500 ℃ - 600 ℃, thiab thaum kawg txias hauv huab cua. Lub thiaj li hu ua tiav txhais tau hais tias ua tiav austenite qauv tau txais thaum cua sov.

Lub hom phiaj ntawm kev ua tiav annealing feem ntau suav nrog: thawj zaug yog txhawm rau txhim kho cov qauv ntxhib thiab tsis sib xws los ntawm kev ua haujlwm kub; Qhov thib ob yog los txo qhov hardness ntawm carbon steel thiab alloy steel castings saum nruab nrab carbon, yog li txhim kho lawv tej kev ua tau zoo (feem ntau, Thaum lub hardness ntawm workpiece yog nruab nrab ntawm 170 HBW-230 HBW, nws yog ib qho yooj yim mus txiav. Thaum lub hardness. siab dua lossis qis dua qhov ntau, nws yuav ua rau txiav nyuaj); qhov thib peb yog kom tshem tawm cov kev ntxhov siab sab hauv ntawm cov hlau casting.

Kev siv ntau yam ntawm kev ua tiav annealing. Tag nrho cov annealing yog tsim nyog rau carbon steel thiab alloy steel castings nrog hypoeutectoid muaj pes tsawg leeg nrog cov ntsiab lus ntawm cov pa roj carbon ntau li ntawm 0.25% mus rau 0.77%. Hypereutectoid steel yuav tsum tsis txhob tag nrho annealed, vim hais tias thaum lub hypereutectoid steel yog rhuab mus rau saum toj no Accm thiab maj mam txias, lub thib ob cementite yuav precipitate raws austenite grain ciam nyob rau hauv ib tug network zoo li, uas ua rau lub zog, plasticity thiab cuam tshuam toughness ntawm cov hlau tseem ceeb. poob.

(2) Isothermal Annealing. Isothermal annealing yog hais txog cov cua kub hlau castings rau 20 ° C - 30 ° C saum toj no Ac3 (los yog Ac1), tom qab tuav rau ib lub sij hawm, sai txias rau lub ncov kub ntawm lub subcooled austenite isothermal transformation nkhaus, thiab ces tuav rau ib lub sij hawm. ntawm lub sijhawm (Pearlite transformation zone). Tom qab austenite hloov mus rau hauv pearlite, nws txias maj mam.

(3) Spheroidizing Annealing. Spheroidizing annealing yog kom sov cov hlau castings mus rau qhov kub me ntsis siab dua Ac1, thiab tom qab ntawd tom qab lub sij hawm ntev ntawm kev txuag hluav taws xob, cov cementite thib ob hauv cov hlau hloov pauv mus rau hauv granular (los yog spherical) cementite, thiab tom qab ntawd maj mam kho cua sov. txheej txheem kom txias rau chav tsev kub.

Lub hom phiaj ntawm spheroidizing annealing muaj xws li: txo cov hardness; ua tus qauv metallographic uniform; txhim kho kev ua haujlwm txiav thiab npaj rau quenching.

Spheroidizing annealing feem ntau yog siv rau eutectoid steels thiab hypereutectoid steels (cov ntsiab lus carbon ntau dua 0.77%) xws li cov cuab yeej carbon steel, alloy caij nplooj ntoos hlav steel, dov bearing steel thiab alloy cuab yeej steel.

(4) Kev ntxhov siab nyem annealing thiab recrystallization annealing. Kev ntxhov siab nyem annealing tseem hu ua low temperature annealing. Nws yog cov txheej txheem uas cov hlau castings tau rhuab kom qis dua Ac1 kub (400 ° C - 500 ° C), tom qab ntawd khaws cia rau lub sijhawm, thiab tom qab ntawd maj mam txias mus rau chav sov. Lub hom phiaj ntawm kev ntxhov siab annealing yog kom tshem tawm cov kev ntxhov siab sab hauv ntawm lub casting. Lub metallographic qauv ntawm cov hlau yuav tsis hloov thaum lub sij hawm kev nyuaj siab annealing txheej txheem. Recrystallization annealing feem ntau yog siv los tshem tawm cov qauv distorted los ntawm kev ua haujlwm txias deformation thiab tshem tawm kev ua haujlwm nyuaj. Cov cua kub rau recrystallization annealing yog 150 ° C - 250 ° C saum toj no qhov kub ntawm recrystallization. Recrystallization annealing tuaj yeem rov tsim cov elongated siv lead ua nplej rau hauv cov pob zeb sib xyaw equiaxed tom qab txias deformation, yog li tshem tawm cov nyhuv ntawm kev ua haujlwm hardening.

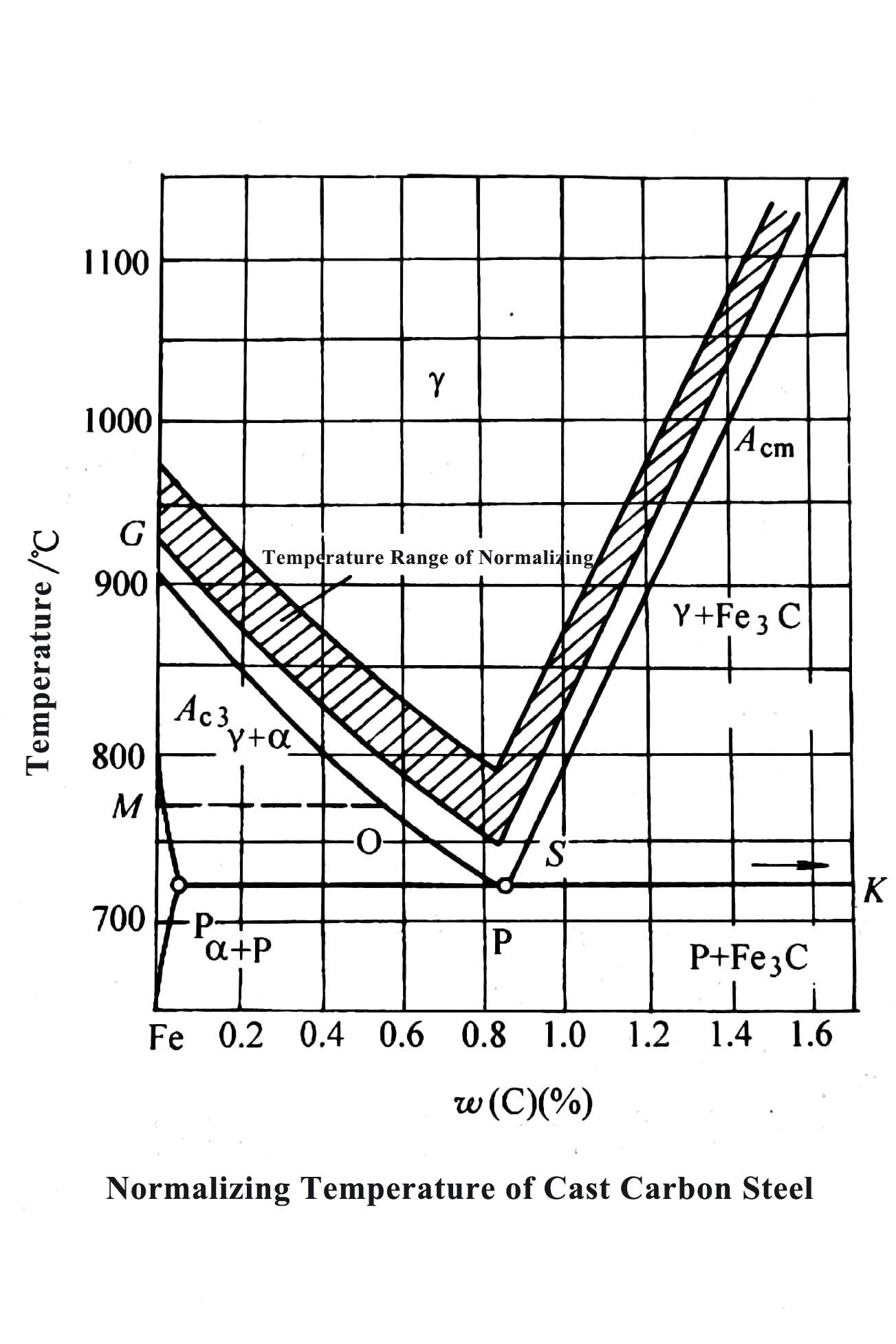

2) normalizing

Normalizing yog kev kho cua sov uas cov hlau tau rhuab mus rau 30 ° C - 50 ° C saum toj no Ac3 (hypoeutectoid steel) thiab Acm (hypereutectoid steel), thiab tom qab lub sij hawm ntawm kev txuag hluav taws xob, nws yog txias rau chav tsev kub hauv huab cua lossis hauv tsev. yuam cua. txoj kev. Normalizing muaj tus nqi cua txias sai dua li annealing, yog li cov qauv normalized zoo dua li cov qauv annealed, thiab nws lub zog thiab hardness kuj siab dua li ntawm cov qauv annealed. Vim lub voj voog luv luv thiab kev siv cov cuab yeej siv siab ntawm normalizing, normalizing yog dav siv nyob rau hauv ntau yam steel castings.

Lub hom phiaj ntawm normalizing yog muab faib ua peb pawg hauv qab no:

(1) Normalizing raws li qhov kawg kev kho cua sov

Rau cov hlau castings uas tsis muaj zog yuav tsum tau, normalizing yuav siv tau raws li qhov kawg kev kho cua sov. Normalizing tuaj yeem kho cov nplej, homogenize cov qauv, txo cov ntsiab lus ferrite hauv cov hlau hypoeutecoid, nce thiab kho cov ntsiab lus pearlite, yog li txhim kho lub zog, hardness thiab toughness ntawm cov hlau.

(2) Normalizing raws li kev kho mob ua ntej cua sov

Rau cov hlau castings nrog cov ntu loj, normalizing ua ntej quenching lossis quenching thiab tempering (quenching thiab kub tempering) tuaj yeem tshem tawm cov qauv Widmanstatten thiab banded qauv, thiab tau txais cov qauv zoo thiab zoo ib yam. Rau lub network cementite tam sim no nyob rau hauv carbon steels thiab alloy cuab yeej steels nrog ib tug carbon cov ntsiab lus ntau tshaj 0.77%, normalizing yuav txo tau cov ntsiab lus ntawm theem nrab cementite thiab tiv thaiv nws los ntawm tsim ib tug nruam network, npaj lub koom haum rau spheroidizing annealing.

(3) Txhim kho kev ua haujlwm txiav

Normalizing tuaj yeem txhim kho qhov kev ua haujlwm ntawm cov pa roj carbon tsawg. Lub hardness ntawm tsawg carbon steel castings yog tsawg heev tom qab annealing, thiab nws yog ib qho yooj yim rau lo rau lub riam thaum txiav, uas ua rau ntau nto roughness. Los ntawm normalizing kev kho cua sov, lub hardness ntawm tsawg carbon steel castings yuav nce mus rau 140 HBW - 190 HBW, uas yog nyob ze rau qhov zoo txiav hardness, yog li txhim kho cov kev ua tau zoo.

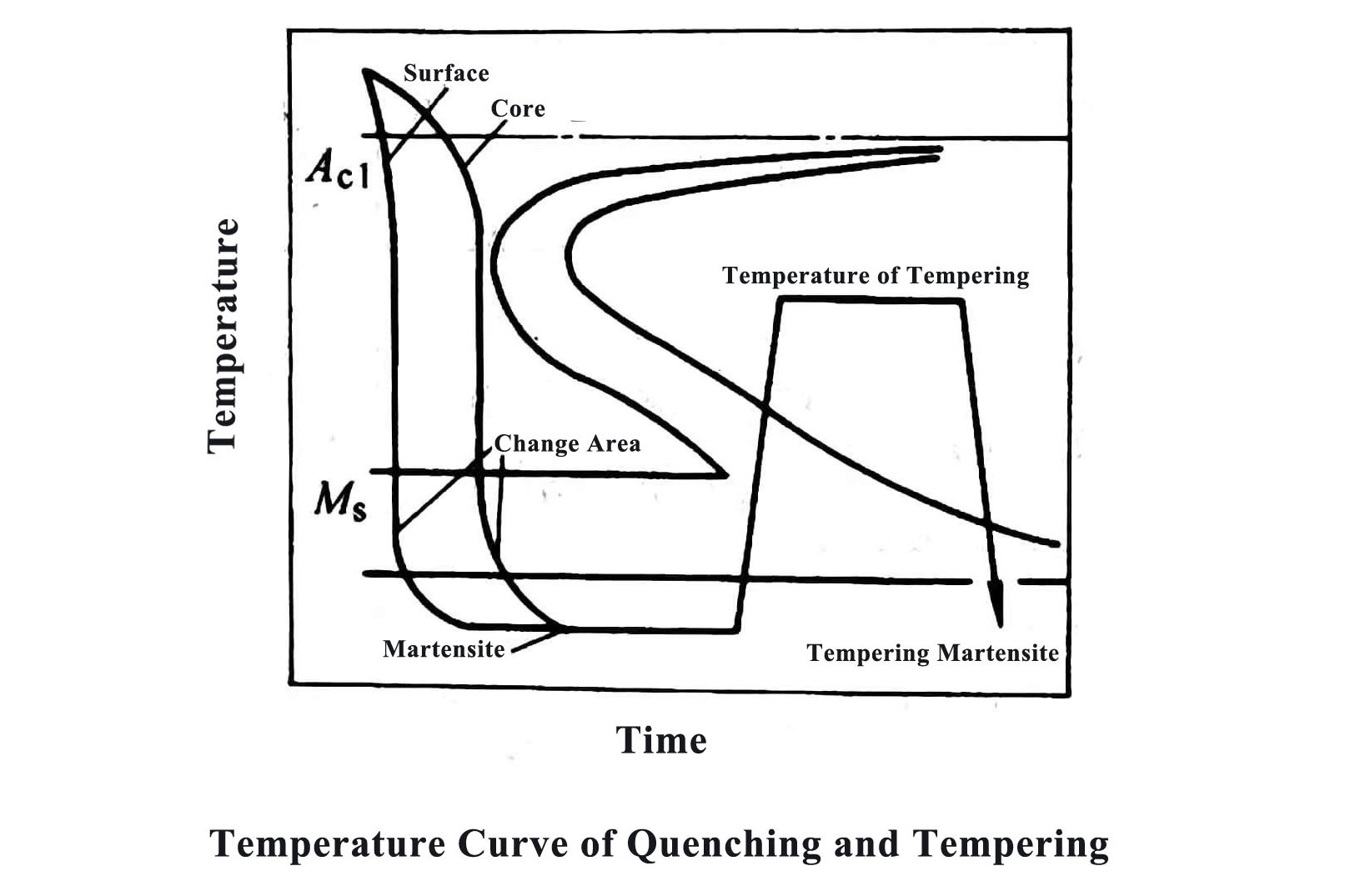

3) Quenching

Quenching yog txheej txheem kev kho cua sov uas cov hlau castings tau muab tso rau qhov kub siab tshaj Ac3 lossis Ac1, thiab tom qab ntawd txias sai sai tom qab tuav rau lub sijhawm kom tau txais cov qauv martensitic tiav. Cov hlau castings yuav tsum tau tempered nyob rau hauv lub sij hawm tom qab lub kub tshaj plaws kom tshem tawm cov quenching kev nyuaj siab thiab kom tau raws li qhov yuav tsum tau txhua yam khoom.

(1) quenching kub

Lub quenching cua sov ntawm hypoeutecoid steel yog 30 ℃ -50 ℃ saum Ac3; quenching cua sov kub ntawm eutectoid steel thiab hypereutectoid hlau yog 30 ℃ -50 ℃ saum Ac1. Hypoeutectoid carbon steel yog rhuab ntawm qhov saum toj no-hais quenching kub thiaj li yuav tau zoo grained austenite, thiab nplua martensite qauv yuav tau tom qab quenching. Cov hlau eutectoid thiab hypereutectoid steel tau spheroidized thiab annealed ua ntej quenching thiab cua sov, yog li tom qab cua sov mus rau 30 ℃ -50 ℃ saum Ac1 thiab tsis tiav austenitized, cov qauv yog austenite thiab ib nrab undissolved fine-grained infiltration Carbon lub cev hais. Tom qab quenching, austenite yog hloov mus rau hauv martensite, thiab undissolved cementite hais yog khaws cia. Vim lub siab hardness ntawm cementite, nws tsis tsuas yog tsis txo cov hardness ntawm steel, tab sis kuj txhim kho nws cov hnav tsis kam. Cov qauv quenched ntawm hypereutectoid hlau yog zoo flaky martensite, thiab nplua granular cementite thiab ib qho me me ntawm cov austenite khaws cia sib npaug ntawm cov matrix. Cov qauv no muaj lub zog siab thiab hnav tsis kam, tab sis kuj muaj qee qhov kev toughness.

(2) Txias nruab nrab rau quenching cua sov txheej txheem

Lub hom phiaj ntawm quenching yog kom tau tiav martensite. Yog li ntawd, qhov cua txias ntawm cov cam khwb cia hlau thaum lub sij hawm quenching yuav tsum ntau dua qhov tseem ceeb ntawm qhov txias txias ntawm cov cam khwb cia hlau, txwv tsis pub cov qauv martensite thiab cov khoom sib thooj tsis tuaj yeem tau txais. Txawm li cas los xij, qhov siab txias heev tuaj yeem ua rau deformation lossis tawg ntawm cov casting. Txhawm rau ua kom tau raws li cov kev xav tau saum toj no tib lub sijhawm, qhov nruab nrab cua txias yuav tsum raug xaiv raws li cov khoom siv ntawm cov casting, los yog cov txheej txheem ntawm staged txias yuav tsum tau saws. Nyob rau hauv qhov kub ntawm 650 ℃ -400 ℃, isothermal transformation tus nqi ntawm supercooled austenite ntawm hlau yog qhov loj tshaj plaws. Yog li ntawd, thaum lub casting yog quenched, ceev ceev yuav tsum tau ensured nyob rau hauv no kub ntau yam. Hauv qab ntawm Ms taw tes, qhov cua txias yuav tsum qeeb qeeb kom tsis txhob deformation lossis tawg. Quenching nruab nrab feem ntau yog siv dej, aqueous tov los yog roj. Nyob rau hauv theem quenching los yog austempering, feem ntau siv xov xwm xws li cov roj kub, molten hlau, molten ntsev los yog molten alkali.

Lub peev xwm txias ntawm cov dej hauv thaj chaw kub siab ntawm 650 ℃ - 550 ℃ yog qhov muaj zog, thiab lub peev xwm txias ntawm cov dej hauv thaj chaw kub tsis tshua muaj ntawm 300 ℃ - 200 ℃ yog qhov muaj zog heev. Dej yog qhov tsim nyog rau quenching thiab txias ntawm carbon steel castings nrog cov duab yooj yim thiab cov hlaws loj. Thaum siv rau quenching thiab txias, dej kub feem ntau tsis siab tshaj 30 ° C. Yog li ntawd, nws yog feem ntau saws los ntxiv dag zog rau cov dej ncig kom cov dej kub nyob rau hauv ib tug tsim nyog ntau yam. Tsis tas li ntawd, cua sov ntsev (NaCl) lossis alkali (NaOH) hauv dej yuav ua rau kom muaj peev xwm ua kom txias ntawm cov tshuaj.

Lub ntsiab kom zoo dua ntawm cov roj raws li ib tug txias nruab nrab yog hais tias tus nqi cua txias nyob rau hauv lub qis kub cheeb tsam ntawm 300 ℃ -200 ℃ yog tsawg tshaj li cov dej, uas yuav ua tau zoo heev txo qhov kev ntxhov siab nyob rau hauv lub quenched workpiece thiab txo qhov muaj peev xwm ntawm deformation. thiab cracking ntawm casting. Nyob rau tib lub sijhawm, lub peev xwm txias ntawm cov roj nyob rau hauv qhov kub ntawm 650 ℃ - 550 ℃ yog qhov qis, uas tseem yog qhov tsis zoo ntawm cov roj raws li qhov nruab nrab quenching. Qhov kub ntawm quenching roj feem ntau tswj ntawm 60 ℃ -80 ℃. Roj yog tsuas yog siv rau quenching ntawm alloy steel castings nrog complex duab thiab quenching ntawm carbon steel castings nrog me me cross-sections thiab complex duab.

Tsis tas li ntawd, molten ntsev kuj tau siv los ua qhov nruab nrab quenching, uas dhau los ua ntsev da dej rau lub sijhawm no. Lub da dej ntsev yog tus cwj pwm los ntawm qhov kub kub thiab nws lub peev xwm txias yog nruab nrab ntawm dej thiab roj. Salt da dej feem ntau yog siv rau austempering thiab theem quenching, nrog rau kev kho cov castings nrog complex duab, me me qhov ntev thiab nruj deformation yuav tsum tau.

4) Tempering

Tempering yog hais txog cov txheej txheem kev kho cua sov uas cov quenched lossis normalized steel castings yog rhuab mus rau ib qho kev xaiv kub qis dua qhov tseem ceeb ntawm Ac1, thiab tom qab tuav rau ib lub sij hawm, lawv txias ntawm tus nqi tsim nyog. Tempering kev kho cua sov tuaj yeem hloov cov qauv tsis ruaj khov uas tau txais tom qab quenching lossis normalizing rau hauv cov qauv ruaj khov kom tshem tawm cov kev ntxhov siab thiab txhim kho cov yas thiab tawv ntawm cov hlau castings. Feem ntau, cov txheej txheem kev kho cua sov ntawm quenching thiab kub tempering kho yog hu ua quenching thiab tempering kev kho mob. Lub quenched steel castings yuav tsum tempered nyob rau hauv lub sij hawm, thiab cov normalized steel castings yuav tsum tempered thaum tsim nyog. Kev ua tau zoo ntawm cov hlau castings tom qab tempering nyob ntawm qhov kub thiab txias, lub sijhawm thiab tus naj npawb ntawm lub sijhawm. Qhov nce ntawm tempering kub thiab ncua sij hawm tuav lub sij hawm txhua lub sij hawm tsis tau tsuas yog txo cov quenching kev nyuaj siab ntawm steel castings, tab sis kuj hloov unstable quenched martensite mus rau hauv tempered martensite, troostite los yog sorbite. Lub zog thiab hardness ntawm steel castings yog txo, thiab cov yas yog ho txhim kho. Rau qee qhov nruab nrab alloy steels nrog alloying cov ntsiab lus uas muaj zog tsim carbides (xws li chromium, molybdenum, vanadium thiab tungsten, thiab lwm yam), lub hardness nce thiab toughness txo thaum tempering ntawm 400 ℃ -500 ℃. Qhov tshwm sim no yog hu ua Secondary hardening, uas yog, hardness ntawm cam khwb cia hlau nyob rau hauv lub xeev tempered mus txog qhov siab tshaj plaws. Nyob rau hauv qhov tseeb ntau lawm, nruab nrab alloy cam khwb cia hlau nrog lwm yam hardening yam ntxwv yuav tsum tau tempered ntau zaus.

(1) Tsawg kub tempering

Qhov kub ntawm qhov kub tsis tshua muaj kub yog 150 ℃ ~ 250 ℃. Tsawg kub tempering tuaj yeem tau tempered martensite qauv, uas yog tsuas yog siv rau quenching siab carbon steel thiab quenching siab alloy steel. Tempered martensite yog hais txog cov qauv ntawm cryptocrystalline martensite ntxiv rau nplua granular carbides. Cov qauv ntawm cov hlau hypoeutectoid tom qab tsis tshua muaj kub tempering yog tempered martensite; Cov qauv ntawm hypereutectoid steel tom qab tsis tshua muaj kub tempering yog tempered martensite + carbides + khaws cia austenite. Lub hom phiaj ntawm qhov kub thiab txias yog tsim nyog los txhim kho lub zog ntawm quenched steel thaum tswj siab hardness (58HRC-64HRC), lub zog siab thiab hnav tsis kam, thaum txo qis kev ntxhov siab thiab brittleness ntawm steel castings.

(2) Nruab nrab kub tempering

Tempering kub ntawm nruab nrab kub yog feem ntau ntawm 350 ℃ -500 ℃. Cov qauv tom qab tempering ntawm nruab nrab kub yog ib tug loj npaum li cas ntawm nplua-grained cementite dispersed thiab faib rau ferrite matrix, uas yog, tempered troostite qauv. Lub ferrite nyob rau hauv tempered troostite qauv tseem khaws cov duab ntawm martensite. Cov kev ntxhov siab sab hauv ntawm cov hlau castings tom qab tempering yog qhov yooj yim tshem tawm, thiab lawv muaj ntau dua elastic txwv thiab tawm los txwv, siab zog thiab hardness, thiab zoo plasticity thiab toughness.

(3) Kub kub tempering

Qhov kub thiab txias tempering feem ntau yog 500 ° C-650 ° C, thiab cov txheej txheem kev kho cua sov uas sib xyaw ua ke thiab tom qab kub kub tempering feem ntau hu ua quenching thiab tempering kho. Cov qauv tom qab kub kub tempering yog tempered sorbite, uas yog, nplua-grained cementite thiab ferrite. Lub ferrite nyob rau hauv tempered sorbite yog polygonal ferrite uas undergoes recrystallization. Hlau castings tom qab kub kub tempering muaj cov khoom zoo txhua yam hais txog lub zog, plasticity thiab toughness. Kub kub tempering yog dav siv nyob rau hauv nruab nrab carbon steel, tsawg alloy steel, thiab ntau yam tseem ceeb yam ntxwv qhov chaw nrog complex rog.

5) Solid SolutionTtreatment

Lub hom phiaj tseem ceeb ntawm kev kho cov tshuaj yog kom yaj carbides los yog lwm yam precipitated theem nyob rau hauv cov khoom tov kom tau ib tug supersaturated ib-theem qauv. Castings ntawm austenitic stainless hlau, austenitic manganese steel thiab nag lossis daus hardening stainless hlau feem ntau yuav tsum tau kho cov tshuaj kho. Qhov kev xaiv ntawm kev daws qhov kub thiab txias yog nyob ntawm cov tshuaj muaj pes tsawg leeg thiab daim duab theem ntawm cov cam khwb cia hlau. Qhov kub ntawm austenitic manganese steel castings feem ntau yog 1000 ℃ - 1100 ℃; Qhov kub ntawm austenitic chromium-nickel stainless hlau castings feem ntau yog 1000 ℃ -1250 ℃.

Qhov siab dua cov ntsiab lus carbon hauv cam khwb cia hlau thiab ntau insoluble alloying ntsiab lus, qhov siab dua nws cov khoom kub yuav tsum yog. Rau nag lossis daus hardening steel castings uas muaj tooj liab, lub hardness ntawm steel castings nce vim nag lossis daus nyuaj tooj liab-nplua nuj theem nyob rau hauv lub as-cam khwb cia lub xeev thaum txias. Txhawm rau ua kom cov qauv muag muag thiab txhim kho kev ua tau zoo, cov hlau castings yuav tsum tau kho kom zoo. Nws cov khoom kub yog 900 ℃ -950 ℃.

6) Precipitation Hardening Treatment

Precipitation hardening kev kho mob yog ib tug dispersion ntxiv dag zog rau kev kho mob nyob rau hauv lub tempering kub ntau yam, tseem hu ua dag aging. Lub ntsiab lus ntawm nag lossis daus hardening kev kho yog tias nyob rau hauv qhov kub thiab txias, carbides, nitrides, intermetallic compounds thiab lwm yam tsis ruaj tsis khov theem nrab yog precipitated los ntawm supersaturated solid tov thiab dispersed nyob rau hauv lub matrix, yog li ua rau cov cam khwb cia steel comprehensive txhim kho txhua yam khoom thiab hardness.

Qhov kub ntawm kev laus kev kho mob ncaj qha cuam tshuam rau qhov kawg kev ua tau zoo ntawm steel castings. Yog tias qhov kub thiab txias qis dhau lawm, cov nag lossis daus hardening theem yuav ua rau qeeb qeeb; Yog tias qhov kub thiab txias siab dhau lawm, qhov sib txuam ntawm cov theem precipitated yuav ua rau overaging, thiab qhov kev ua tau zoo tshaj plaws yuav tsis tau. Yog li ntawd, lub foundry yuav tsum xaiv qhov tsim nyog aging kub raws li cam khwb cia hlau qib thiab cov kev ua tau zoo ntawm cov hlau casting. Kev laus kub ntawm austenitic tshav kub-resistant cam khwb cia hlau yog feem ntau 550 ℃ -850 ℃; Kev laus kub ntawm lub zog siab nag lossis daus hardening cam khwb cia hlau feem ntau yog 500 ℃.

7) Kev kho kev ntxhov siab

Lub hom phiaj ntawm kev kho cua sov kev ntxhov siab yog txhawm rau tshem tawm kev ntxhov siab casting, quenching kev ntxhov siab thiab kev ntxhov siab tsim los ntawm machining, thiaj li kom ruaj khov qhov loj ntawm cov casting. Kev kho cua sov ntawm kev ntxhov siab feem ntau yog rhuab mus rau 100 ° C-200 ° C hauv qab Ac1, tom qab ntawd khaws cia rau lub sijhawm, thiab thaum kawg txias nrog lub qhov cub. Cov qauv ntawm cov hlau casting tsis hloov thaum lub sij hawm kev ntxhov siab. Carbon steel castings, low-alloy steel castings thiab high-alloy steel castings tuaj yeem raug kho los ntawm kev ntxhov siab.

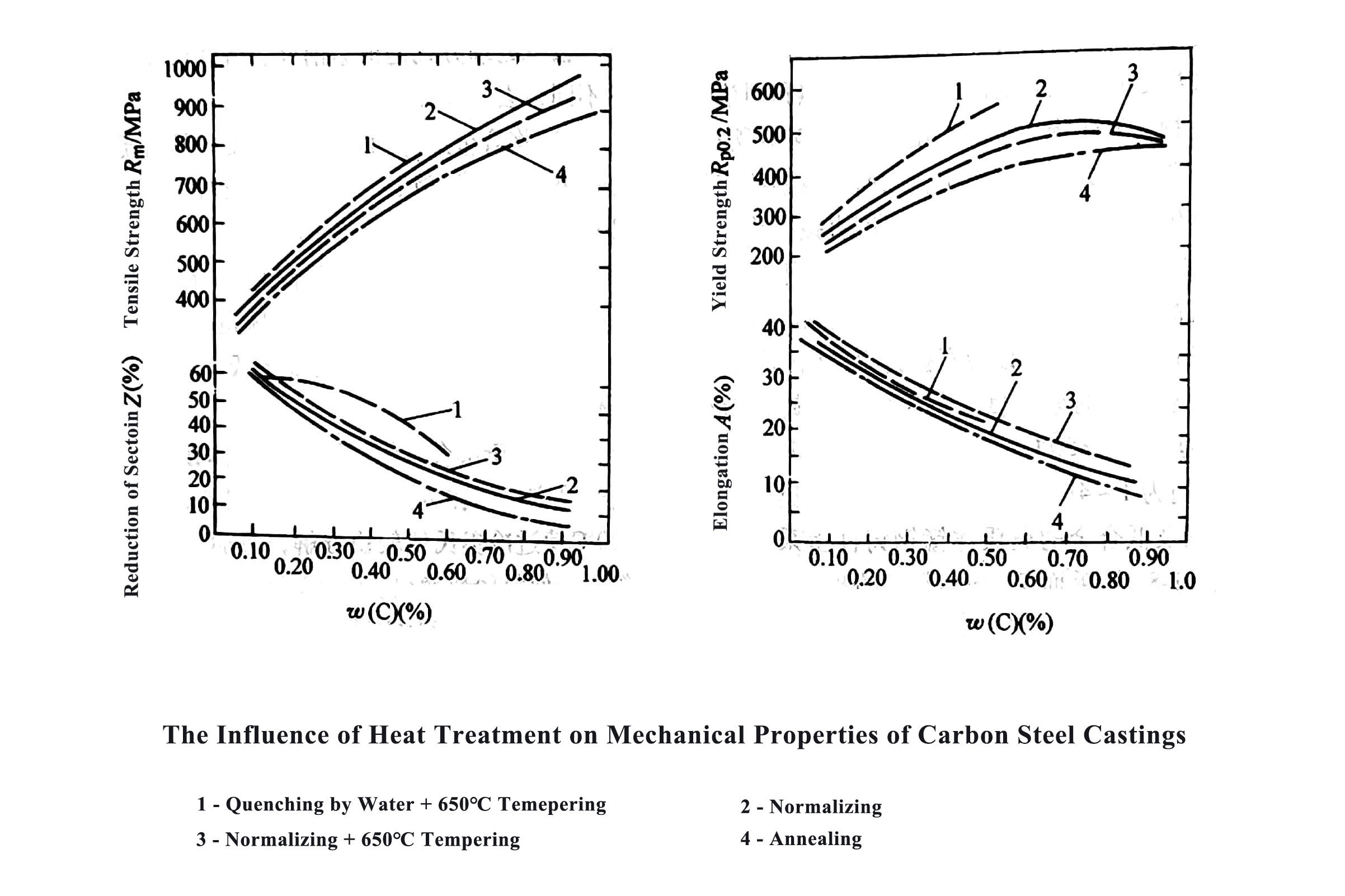

4. Cov nyhuv ntawm kev kho cua sov ntawm cov khoom ntawm cov hlau Castings

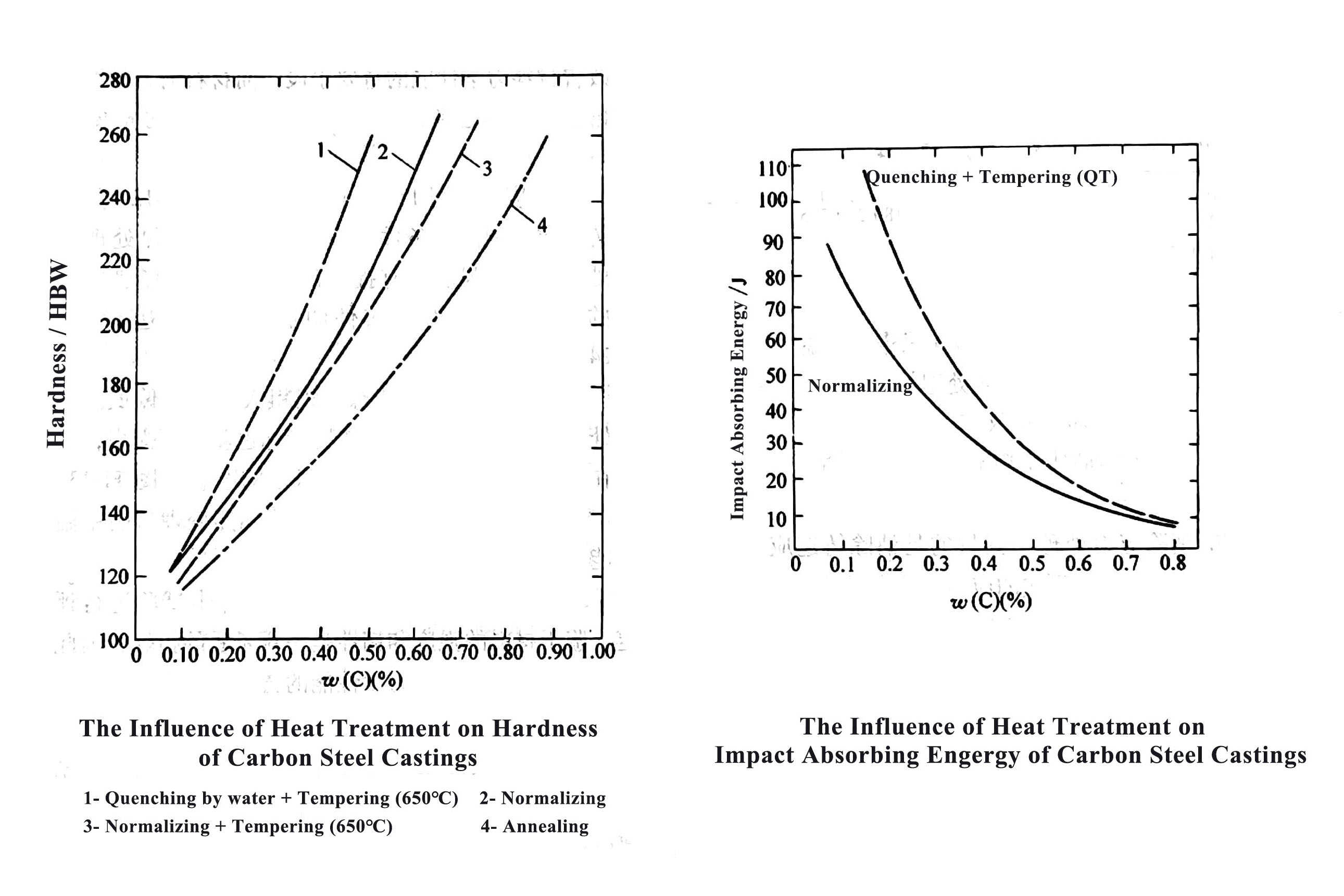

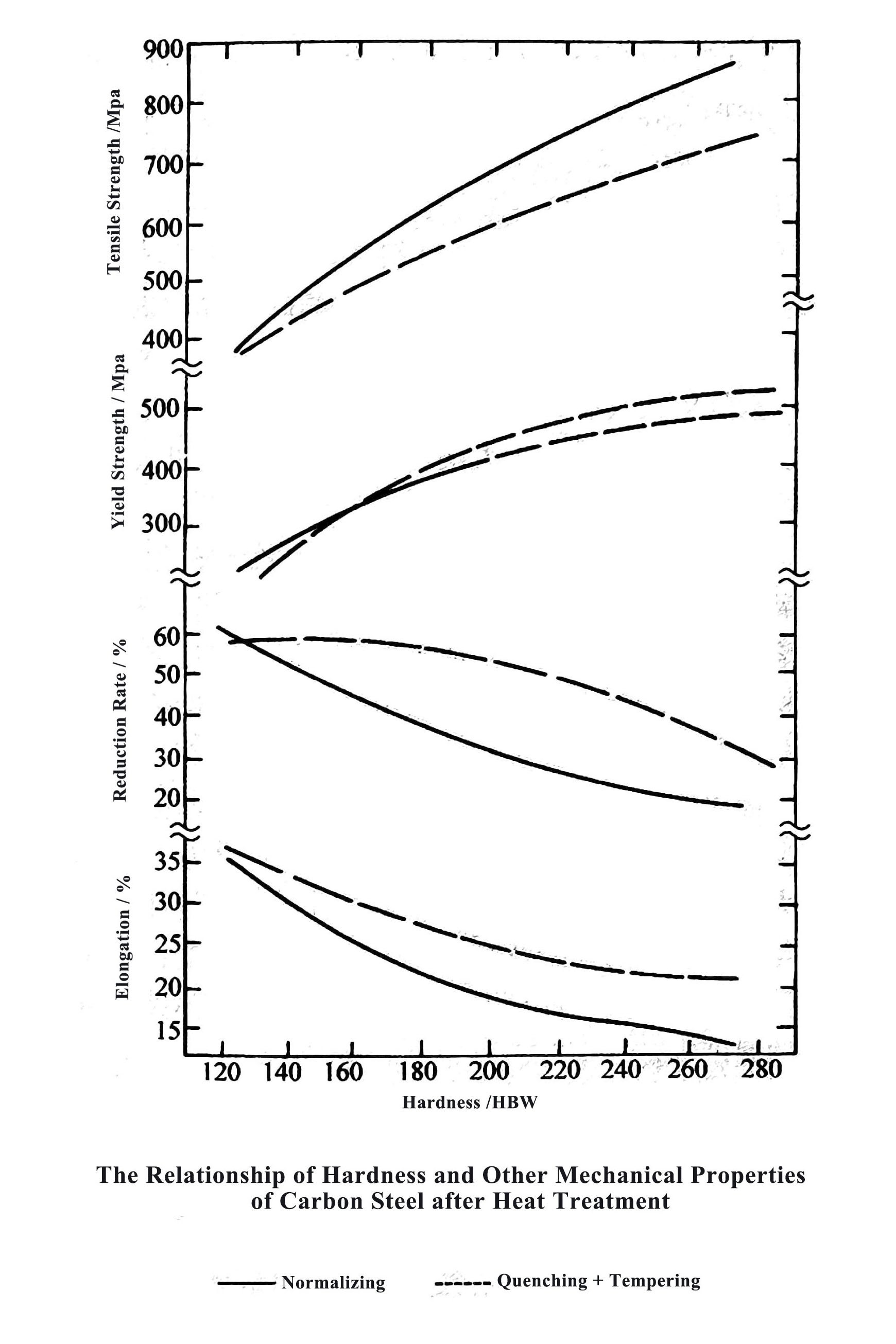

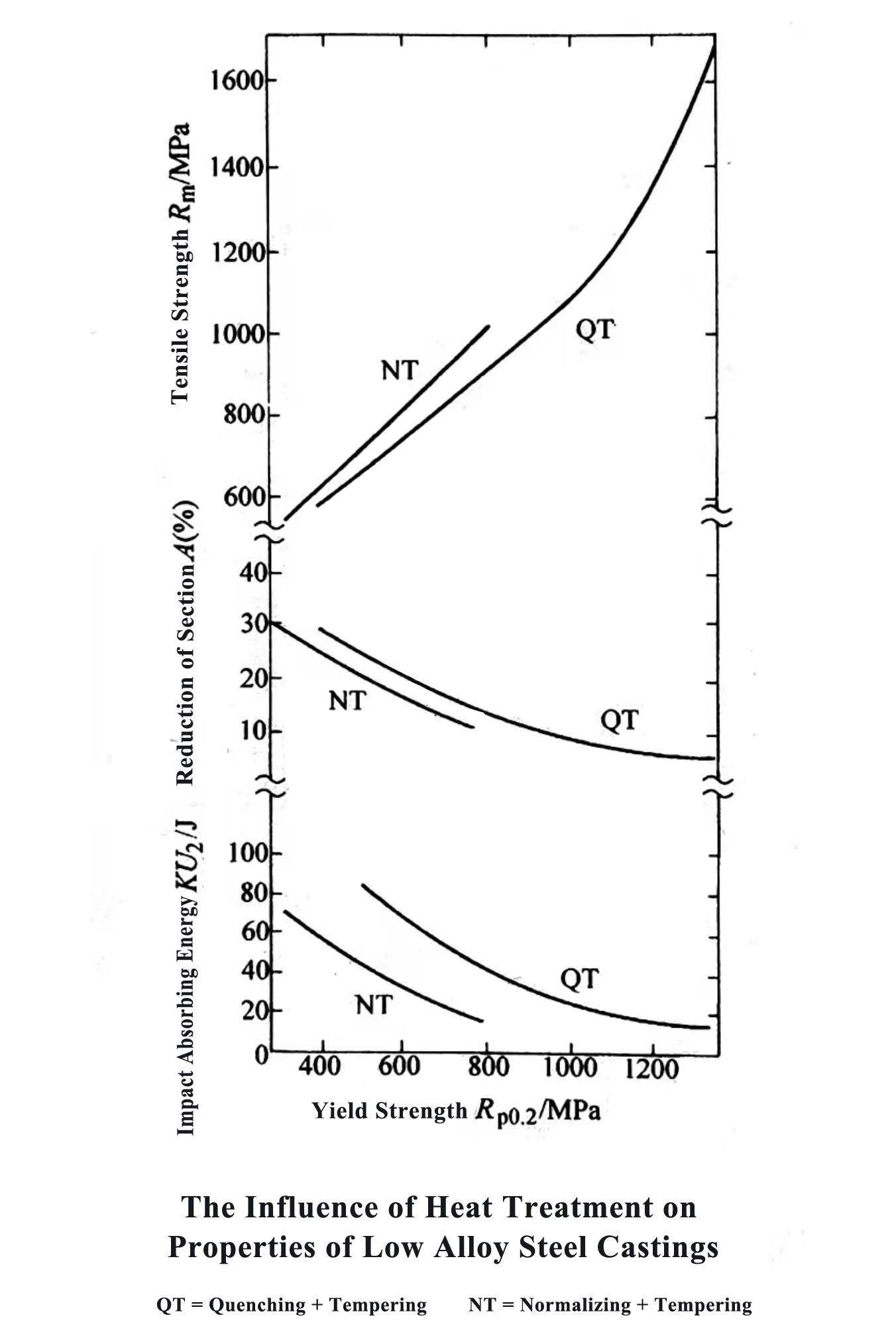

Ntxiv rau qhov kev ua tau zoo ntawm cov hlau castings nyob ntawm cov tshuaj muaj pes tsawg leeg thiab cov txheej txheem casting, kev kho cua sov sib txawv kuj tuaj yeem siv los ua kom nws muaj cov khoom siv zoo heev. Lub hom phiaj ntawm cov txheej txheem kev kho cua sov yog txhawm rau txhim kho qhov zoo ntawm cov castings, txo qhov hnyav ntawm cov castings, ncua kev pab cuam lub neej thiab txo cov nqi. Kev kho cua sov yog ib qho tseem ceeb hauv kev txhim kho cov khoom siv hluav taws xob ntawm castings; mechanical zog ntawm castings yog ib qho tseem ceeb qhia rau judging cov nyhuv ntawm kev kho cua sov. Ntxiv nrog rau cov khoom hauv qab no, lub hauv paus tseem yuav tsum xav txog yam xws li cov txheej txheem ua haujlwm, txiav kev ua haujlwm thiab kev siv cov kev xav tau ntawm cov castings thaum tshav kub-kho steel castings.

1) Kev cuam tshuam ntawm kev kho cua sov ntawm lub zog ntawm Castings

Nyob rau hauv cov xwm txheej ntawm tib cam khwb cia hlau muaj pes tsawg leeg, lub zog ntawm steel castings tom qab sib txawv kev kho cua sov txheej txheem muaj ib tug nyiam nce. Feem ntau hais lus, lub zog tensile ntawm carbon steel castings thiab qis alloy steel castings tuaj yeem ncav cuag 414 Mpa-1724 MPa tom qab kev kho cua sov.

2) Cov nyhuv ntawm kev kho cua sov ntawm Plasticity ntawm Steel Castings

Raws li-cam khwb cia hlau castings yog ntxhib thiab plasticity yog tsawg. Tom qab kev kho cua sov, nws cov microstructure thiab plasticity yuav raug txhim kho raws li. Tshwj xeeb tshaj yog cov yas ntawm steel castings tom qab quenching thiab tempering kev kho mob (quenching + kub tempering) yuav ua tau zoo heev.

3) Toughness ntawm hlau Castings

Lub toughness Performance index ntawm steel castings feem ntau raug soj ntsuam los ntawm kev ntsuam xyuas cuam tshuam. Txij li thaum lub zog thiab toughness ntawm steel castings yog ib tug khub ntawm contradictory indicators, lub foundry yuav tsum ua kom tiav kev txiav txim siab los xaiv ib tug haum kev kho cua sov txheej txheem nyob rau hauv thiaj li yuav ua kom tiav cov khoom txhua yam uas yuav tsum tau los ntawm cov neeg muas zaub.

4) Cov nyhuv ntawm kev kho cua sov ntawm lub hardness ntawm Castings

Thaum lub hardenability ntawm cov cam khwb cia hlau yog tib yam, hardness ntawm cam khwb cia hlau tom qab kev kho cua sov yuav roughly reflected lub zog ntawm cam khwb cia hlau. Yog li ntawd, lub hardness yuav siv tau raws li intuitive Performance index los kwv yees qhov kev ua tau zoo ntawm cam khwb cia hlau tom qab kev kho cua sov. Feem ntau hais lus, qhov hardness ntawm carbon steel castings tuaj yeem ncav cuag 120 HBW - 280 HBW tom qab kev kho cua sov.

Post lub sij hawm: Lub Xya hli ntuj-12-2021