Kev nqis peev Casting Foundry

Kev nqis peev casting, tseem hu ua poob ciab casting lossis precision casting, yog txheej txheem uas tau siv ntau txhiab xyoo, nrog rau cov txheej txheem wax ploj yog ib qho ntawm cov txheej txheem qub tshaj plaws uas paub txog hlau.

Vim lub complex qauv nyob rau hauv dimension thiab geometric, lub peev castings yog tsim kom ncav cuag net zoo los yog ze net zoo, txo qhov yuav tsum tau rau lwm yam txheej txheem xws li lathing, tig los yog lwm yam.CNC machiningtxheej txheem.

Kev nqis peev casting yog txheej txheem tsim khoom uas tuaj yeem taug qab tau ntau dua 5,000 xyoo dhau los. Txij thaum ntawd los, thaum beeswax tsim cov qauv, mus rau niaj hnub no cov cuab yeej siv siab, cov ntaub ntawv refractory thiab cov alloys tshwj xeeb, cov khoom siv ploj ploj kom ntseeg tau tias cov khoom zoo yog tsim nrog qhov zoo ntawm qhov tseeb, rov ua dua, thiab kev ncaj ncees.

Kev nqis peev casting muab nws lub npe los ntawm qhov tseeb tias tus qauv yog nqis peev, lossis ib puag ncig, nrog cov khoom siv refractory. Cov qauv siv quav ciab xav tau kev saib xyuas hnyav rau lawv tsis muaj zog txaus los tiv thaiv cov rog thaum lub sijhawm ua pwm.

Kev nqis peev Casting Foundry

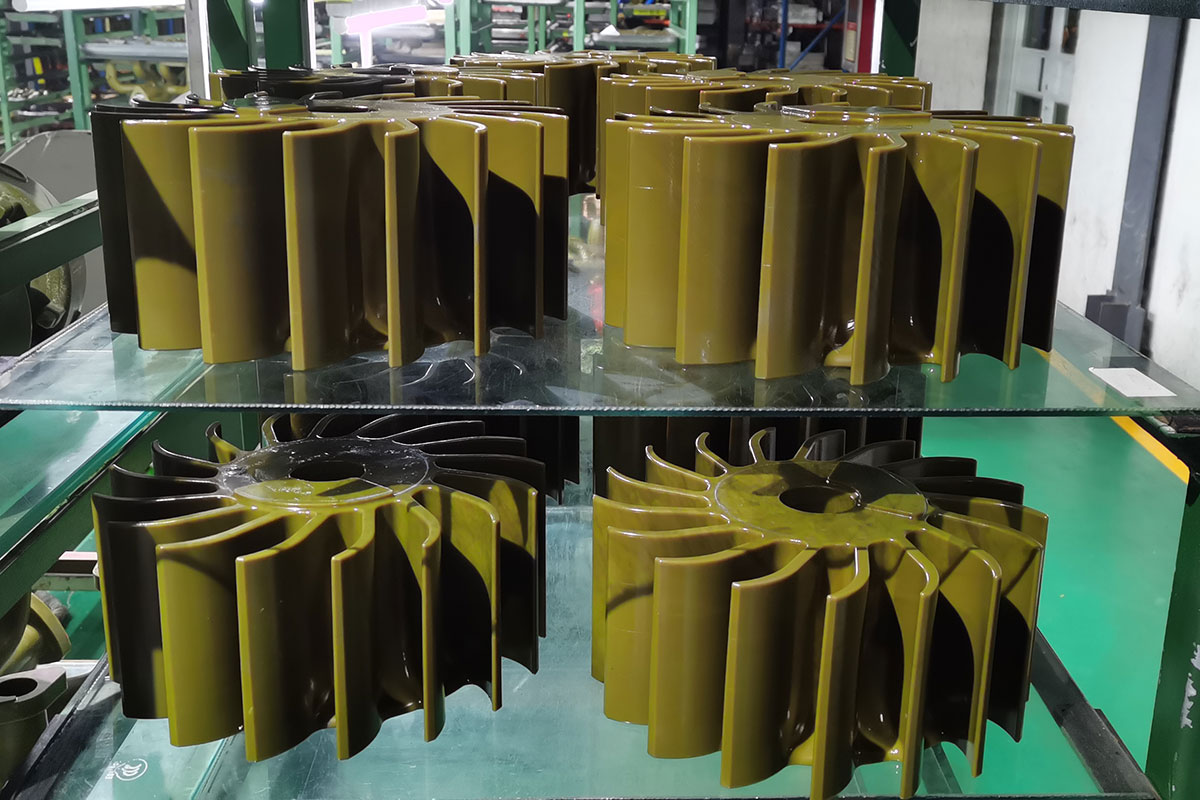

Dab tsi peb tuaj yeem ua tiav los ntawm Poob Wax Peev Casting

Poob ciab peev castings nrog silica sol raws li cov ntaub ntawv binder tuaj yeem ncav cuag qhov kam rau siab qib CT4 ~ CT7 raws li ISO 8062. Peb cov cuab yeej ua haujlwm siab thiab cov txheej txheem automation tswj tso cai rau kev ua siab ntev thiab rov ua dua li ze li ± 0.1 hli. Covploj wax casting qhov chawKuj tseem tuaj yeem tsim nyob rau hauv ntau qhov loj, lawv tuaj yeem ua me me li 10 hli ntev x 10 hli dav x 10 hli siab thiab hnyav li 0.01 kg, lossis loj li 1000 hli ntev thiab hnyav li 200 kg. .

RMC yog lub chaw tsim khoom lag luam ntawm cov peev txheej zoo tshaj plaws uas tau cog lus los xa cov khoom zoo, tus nqi zoo tshaj thiab cov neeg siv khoom tshwj xeeb. RMC muaj cov kev paub dhau los, kev txawj ntse thiab cov txheej txheem kev lees paub zoo kom ua tau raws li qhov xav tau thiab ntseeg tau xa ntau yam ntawm castings nrog kev ua haujlwm ntxiv.

- • Max Loj ntawm Casting1,000mm × 800mm × 800mm

- • Cast Weight RangeNyhav: 0.5-200 kg

- • Muaj Peev Xwm Txhua Xyoo:3,000 tons

- • Bond Materials for Shell Building:Silica Sol, Dej iav los yog lawv cov khoom sib tov.

- • Casting Tolerances:CT4 ~ CT7 raws li ISO 8062 lossis ntawm Kev Thov.

Plhaub Ua Thaum Peev Casting

Dab tsi hlau thiab alloys peb tuaj yeem nchuav los ntawm kev nqis peev Casting

Covpeev casting foundryntawm RMC muaj peev xwm ua tau raws li ntau yam ntawm cov khoom siv alloys tsim thiab specifications raws li ASTM, SAE, AISI, ACI, DIN, GOST, EN, ISO, thiab GB qauv. Peb muaj ntau tshaj 100 qhov sib txawv ferrous thiab non-ferrous alloys uas peb cam khwb cia qhov chaw siv txoj kev tsim qauv.

- • Grey Cam khwb cia hlau:HT150, HT200, HT250, HT300, HT350; EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300, EN-GJL-350; GG10, GG15, GG20, GG25, GG30, GG40; ASTM A48 Grey Iron Qib Qib 20, Chav Kawm 25, Chav Kawm 30, Chav Kawm 35, Chav Kawm 40, Chav Kawm 45, Chav Kawm 50, Chav Kawm 55, Chav Kawm 60.

- • Ductile Cast Iron (Nodular Iron):Tuam Tshoj GB QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2; GGG40, GGG45, GGG50, GGG60, GGG70, GGG80; EN-GJS-400-18, EN-GJS-400-15, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2, EN- GJS-800-2; ASTM A536 Ductile Hlau Qib 60-40-18, 65-45-12, 70-50-05, 80-60-03, 100-70-03, 120-90-02.

- •Carbon Steel:AISI 1020 ~ AISI 1060, C30, C40, C45.

- •Hlau alloy:ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo, thiab lwm yam.

- •Stainless hlau:AISI 304, AISI 304L, AISI 316, AISI 316L,TIAB SA 347, AISI 430, 1.4401, 1.4404, 1.4408, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571, CF3, CF3M, CF8, CF8M... thiab lwm yam.

- •Duplex Stainless hlau (DSS)thiabPrecipitation Hardening (PH) Stainless hlau

- • Brass, Bronze thiab lwm yam Copper-based Alloys

- •Nickel Based Alloy (Inconel 625, Inconel 713, Inconel 718 thiab lwm yam), Cobalt Raws li Alloys

- • Corrosion-resistant Steel, Seawater-resistant Steel, High-temperature Steel, High-tensile Steel, Duplex Stainless hlau.

- • Aluminium Alloy A356, A360

- • Lwm yam Alloys raws li kev thov lossis raws li ASTM, SAE, AISI, GOST, DIN, EN, ISO, thiab GB.

Stainless hlau Investment Casting

Peev Casting Pwm

Al Pwm rau Poob Wax Casting

Hlau Mould rau kev nqis peev Casting

Puv Machined Aluminium Alloy Pwm rau Precision Casting

Cov kauj ruam ntawm Poob Wax Investment Casting

Kev nqis peev casting yog txheej txheem ntau kauj ruam uas tsim cov duab ze-netprecision casting qhov chaw. Cov txheej txheem pib nrog wax raug txhaj rau hauv qhov tuag los tsim cov qauv ntawm cov khoom tiav. Cov qauv yog ces affixed rau wax runner tuav los tsim pawg.

Thaum lub sij hawm peev casting txheej txheem, ib lub tshuab tshwj xeeb dips cov pawg ntau zaus mus rau hauv slurry los tsim ib lub plhaub ceramic, thiab tom qab ntawd cov wax raug tshem tawm hauv chav autoclave. Thaum cov wax raug tshem tawm, lub plhaub ceramic raug rho tawm haujlwm thiab tom qab ntawd ntim cov hlau molten los tsim ib feem. Ib qho txiaj ntsig ntawm kev nqis peev casting yog qhov siv quav ciab tuaj yeem rov qab siv dua.

Kev nqis peev casting (Post wax casting txheej txheem) yuav tsum muaj hlau tuag (feem ntau nyob rau hauv txhuas), siv quav ciab, ceramic slurry, rauv, molten hlau, thiab lwm yam tshuab xav tau rau kev txhaj tshuaj wax, xuab zeb blasting, vibratory tumbling, txiav, thiab sib tsoo. Kev nqis peev casting txheej txheem feem ntau suav nrog cov kauj ruam hauv qab no:

1- Hlau Tuag Ua

Raws li cov duab kos thiab cov kev xav tau ntawm qhov xav tau cam khwb cia, cov hlau tuag lossis pwm, feem ntau hauv txhuas, yuav tsim thiab tsim. Cov kab noj hniav yuav tsim tib qhov loj thiab cov qauv ntawm qhov xav tau cam khwb cia.

2- Tsob tshuaj txhaj

Kuj tseem hu ua qauv tsim, Poob ciab casting qauv yog tsim los ntawm kev txhaj tshuaj molten wax rau hauv cov hlau tuag saum toj no.

3- Slurry Assembly

Cov qauv siv quav ciab yog tom qab ntawd txuas rau lub rooj vag, uas feem ntau yog cov txheej txheem los ntawm cov hlau molten flsows mus rau pwm kab noj hniav. Tom qab ntawd, ib qho qauv zoo li tsob ntoo raug tsim, uas yog tsim rau kev tsim khoom loj.

4- Lub Tsev Plhaub

Kev nqis peev castings txheej plhaub casing yog tsim los ntawm dipping rau hauv ceramic da dej thiab ces tam sim ntawd coated nrog xuab zeb rau ob peb zaug.

5- De-waxing

Lub puab kab noj hniav ntawm precision peev casting yog ces dewaxed, uas tawm ib tug hollow txheej ceramic plhaub txheej. Cov hollows tsuas yog tib qhov chaw raws li qhov xav tau castings.

6-Pre-Pouring Analysis

Kev tsom xam ua ntej ua ntej txhais tau hais tias qhov chaw tsim khoom yuav tsum tau kuaj xyuas thiab tshuaj xyuas cov tshuaj muaj pes tsawg leeg ntawm cov hlau molten kom pom tias lawv ua tau raws li cov lej xav tau lossis lub hnub qub. Qee lub sij hawm, qhov kev ntsuam xyuas no yuav ua tau ntau zaus.

7- Pouring & Solidification

Ceramic plhaub nrog kab noj hniav yuav tsum tau pre-rhuab ua ntej pouring. Qhov no tiv thaiv kev poob siab thiab lub plhaub ceramic los ntawm kev tawg thaum cov kua hlau ntawm qhov kub siab yog nchuav rau hauv kab noj hniav.

8- Sawing los yog txiav

Thaum cov hlau tau txias thiab ua kom khov, cov cam khwb cia yog muab tshem tawm ntawm lub rooj vag system ntoo pawg los ntawm kev co, txiav los yog kev sib txhuam sawing tawm ntawm tus neeg cam khwb cia ib feem.

9- Kev txhaj tshuaj blasting thiab kev ua haujlwm thib ob

Qhov casting yog ces tag nrho customized los ntawm kev sib tsoo los yog ntxiv kev kho cua sov. Secondary machining los yog kev kho deg kuj yuav tsum tau nyob ntawm seb qhov yuav tsum tau ua.

10-Ntim thiab xa khoom

Tom qab ntawd cov khoom siv pov tseg uas ploj lawm yuav raug kuaj tag nrho rau qhov ntev, qhov chaw, cov khoom siv kho tshuab thiab lwm yam yuav tsum tau kuaj ua ntej ntim thiab xa khoom.

Wax Qauv

Plhaub kom qhuav

Cooling thiab Solidification

Sib tsoo thiab ntxuav

Yuav Ua Li Cas Peb Tshawb Xyuas Cov Peev Castings

- • Spectrographic thiab phau ntawv txheeb xyuas kom muaj nuj nqis

- • Metallographic tsom xam

- • Kev ntsuam xyuas qhov ntev

- • CMM

- • Brinell, Rockwell thiab Vickers hardness tshuaj xyuas

- • Kev tshuaj xyuas cov cuab yeej cuab tam

- • Kev ntsuas qhov kub thiab txias tsis zoo

- • Kev tshuaj xyuas huv

- • UT, MT thiab RT tshuaj xyuas

- • Staic thiab Dynamic Balancing

- • Kev sib khi thiab kev ntsuas siab

Wax Replicas

Dab tsi yog qhov chaw peb tso siab rau kev nqis peev Casting

Toolings Warehouse

Tsob Ntoo Txhaj Tshuaj

Tsob Ntoo Txhaj Tshuaj

Ciab Txhaj Tshuab

Ua Plhaub

Plhaub Ua

Shell Drying Rhiav

Plhaub rau Investment Casting

Plhaub kom qhuav

Plhaub Npaj rau Casting

Cooling thiab Solidification

Kev nqis peev Casting

Qhov Kev Lag Luam Peb Cov Peev Castings tau pab

Qhov chaw ua los ntawm peev castingyog siv los cam khwb cia ntau yam khoom, nrog rau kev ua tau zoo, kev ua haujlwm siab ua haujlwm ntawm cov txheej txheem nyuaj.Daim ntawv thov ntawm peev casting qhov chaw npog ntau yam kev lag luam, hauv peb lub tuam txhab lawv feem ntau yog siv rau hauv cov hauv qab no:

| •Valve thiab Pump Parts | • Cov khoom siv logistics |

| • Cov Tsheb Loj | • Cov khoom siv ua liaj ua teb |

| • Automotive | •Hydraulic |

| • Cov khoom siv hauv tsev | • Tsheb ciav hlau txoj kev tsheb ciav hlau |

Daim ntawv thov kev nqis peev Castings

HomKev nqis peev CastingsPeb Ua Tau

Peb tuaj yeem ua tau ntau dua los ntawm kev muab peev Casting thiab lwm yam kev pabcuam:

Ntawm RMC, peb txaus siab rau peb tus kheej hauv kev muab peb cov neeg siv khoom kev pabcuam los ntawm patter tsim rautiav castingsthiab cov txheej txheem thib ob. Peb cov kev pabcuam suav nrog:

- - Cov qauv tsim thiab nqe lus pom zoo.

- - Tus Qauv Tsim Qauv.

- - Kev Tshawb Fawb Txog Kev Tsim Khoom thiab Kev Tsim Kho.

- - Manufacturing Flexibility.

- - Kev Tsim Nyog thiab Kev Xeem.

- - Kev kho cua sov thiab kev kho deg muaj.

- - Outsourcing Manufacturing Peev Xwm

Stainless hlau Investment Castings

Vim li cas koj xaiv RMC los tsim cov peev Castings

Muaj ob peb lub laj thawj xaiv RMC ua koj qhov chaw rau peev castings. Thaum koj txiav txim siab rau koj, koj yuav mob siab txog cov ntsiab lus hauv qab no uas peb ua haujlwm tau zoo:

- - Pab pawg Engineering uas nws cov tswv cuab tsom mus rau cov hlau casting.

- - Kev paub ntau yam nrog cov geometry nyuaj

- - Ntau yam khoom siv, suav nrog ferrous thiab non-ferrous alloys

- - Hauv tsevCNC machiningpeev xwm

- - Ib qho kev daws teeb meem rau kev nqis peev castings thiab cov txheej txheem thib ob

- - Zoo ib yam guaranteed thiab kev txhim kho tas mus li.

- - Pab neeg ua haujlwm nrog rau cov tsim khoom, engineers, foundryman, machinist thiab cov kws tshaj lij tsim khoom.