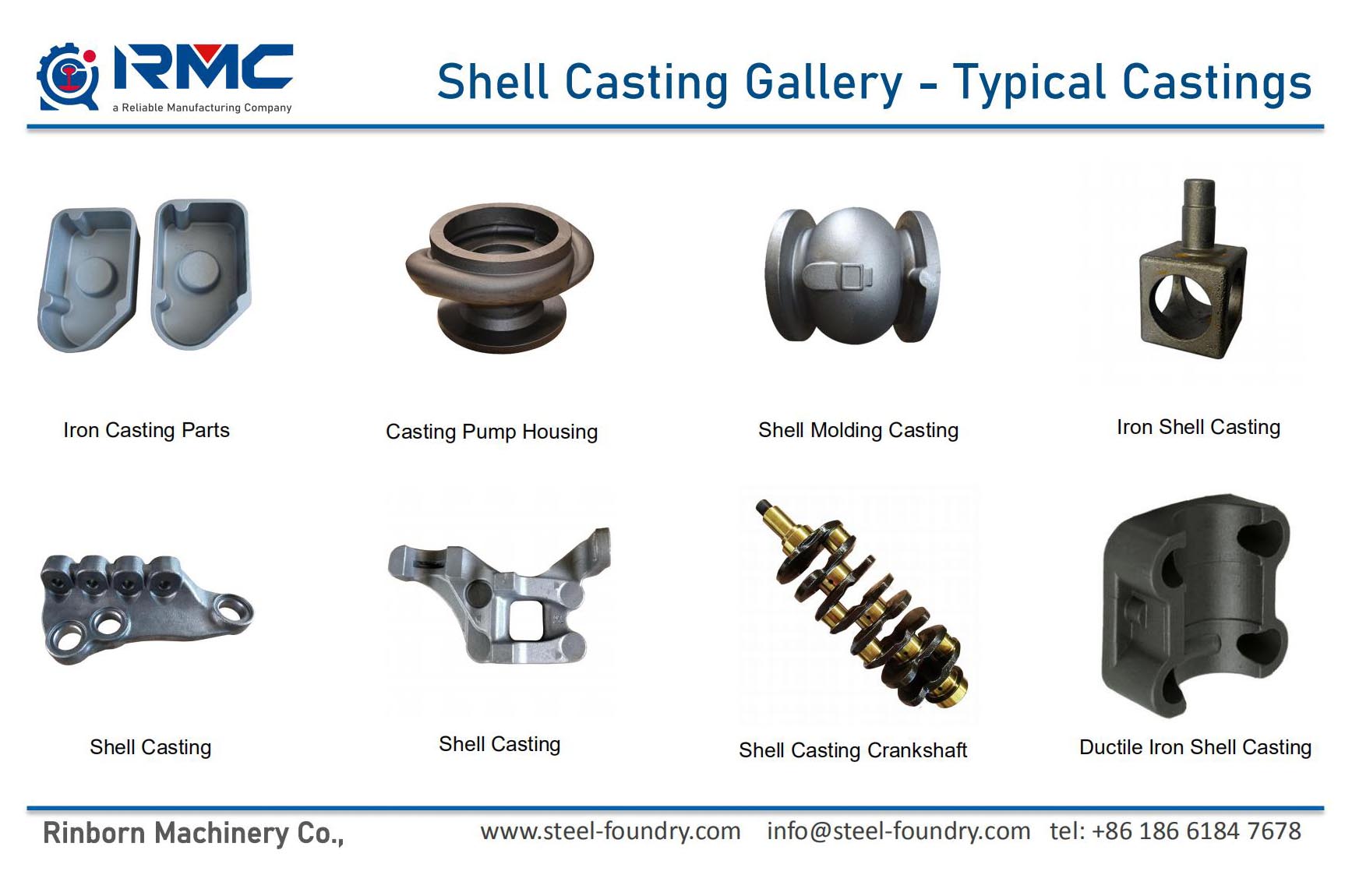

Custom grey cam khwb cia hlauplhaub moldsnrog kev pabcuam ntawmKev kho cua sovthiab kho qhov chaw.

Plhaub moldingtxheej txheem tseem hu ua pre-coated resin xuab zeb casting txheej txheem, kub plhaub molding castings los yog cov txheej txheem casting. Lub ntsiab molding khoom yog pre-coated phenolic resin xuab zeb, uas yog kim tshaj li ntsuab xuab zeb thiab furan resin xuab zeb. Ntxiv mus, cov xuab zeb no tsis tuaj yeem siv dua.

Furan resin self-hardening xuab zeb casting txheej txheem ( txheej txheem nobake) siv cov furan cob coated xuab zeb los tsim cov pwm pwm. Tom qab sib tov cov xuab zeb qub (los yog cov xuab zeb reclaimed), kua furan resin thiab kua catalyst tusyees, thiab muab tso rau hauv lub thawv tub ntxhais (los yog xuab zeb lub thawv), thiab tom qab ntawd muab nruj nreem rau hauv pwm los yog pwm hauv lub thawv tub ntxhais (los yog xuab zeb). box) ntawm chav tsev kub. Tom qab ntawd cov pwm casting lossis casting core raug tsim, uas yog hu ua self-hardening txias-core box molding (core), los yog nws tus kheej-hardening method (core).

Vim hais tias cov pwm yog tsim nyob rau hauv chav tsev kub thiab tsis xav tau cua sov, tus kheej-hardening xuab zeb casting tseem hu ua tsis muaj-ci casting txheej txheem. Tus kheej-hardening txoj kev yuav muab faib ua acid-catalyzed furan resin thiab phenolic resin xuab zeb self-hardening txoj kev, urethane resin xuab zeb nws tus kheej-hardening txoj kev thiab phenolic monoester nws tus kheej-hardening txoj kev.

Raws li tus kheej-hardening txias thawv binder xuab zeb, furan resin xuab zeb yog qhov ntxov tshaj plaws thiab tam sim no feem ntau siv hluavtaws binder xuab zeb hauv Suav foundry. Tus nqi ntawm cov resin ntxiv rau hauv molding xuab zeb yog feem ntau 0.7% mus rau 1.0%, thiab cov nyiaj ntxiv resin hauv cov xuab zeb feem ntau yog 0.9% mus rau 1.1%. Cov ntsiab lus ntawm dawb aldehyde nyob rau hauv furan resin yog qis dua 0.3%, thiab qee qhov chaw tsim khoom tau poob qis dua 0.1%. Hauv cov foundries hauv Suav teb, furan resin self-hardening xuab zeb tau mus txog qib thoob ntiaj teb tsis hais txog cov txheej txheem tsim khoom thiab qhov zoo ntawm cov castings.

Grey hlau, los yog grey cam khwb cia hlau, yog ib hom cam khwb cia hlau uas muaj graphite microstructure. Nws yog lub npe hu ua grey xim ntawm lub pob txha tawg nws cov ntaub ntawv. Grey cam khwb cia hlau yog siv rau cov tsev nyob qhov twg qhov nruj ntawm cov khoom yog qhov tseem ceeb tshaj nws lub zog tensile, xws li lub tog raj kheej combustion engine cylinder blocks, twj tso kua mis vaj tse, valve lub cev, lub thawv hluav taws xob, counterweights thiab hniav castings. Grey cam khwb cia hlau lub siab thermal conductivity thiab lub taub hau muaj peev xwm feem ntau yog siv los ua cam khwb cia hlau cookware thiab disc nres rotors.

Ib qho tshuaj lom neeg muaj pes tsawg leeg kom tau txais graphitic microstructure yog 2.5 mus rau 4.0% carbon thiab 1 mus rau 3% silicon los ntawm qhov hnyav. Graphite tuaj yeem tuav 6 mus rau 10% ntawm qhov ntim ntawm cov hlau grey. Silicon yog ib qho tseem ceeb rau kev ua grey hlau tsis zoo li cov hlau cam khwb cia dawb, vim hais tias silicon yog ib qho graphite stabilizing caij hauv cam khwb cia hlau, uas txhais tau hais tias nws pab cov alloy tsim graphite es tsis txhob hlau carbides; ntawm 3% silicon yuav luag tsis muaj cov pa roj carbon nyob rau hauv tshuaj ua ke nrog cov hlau.

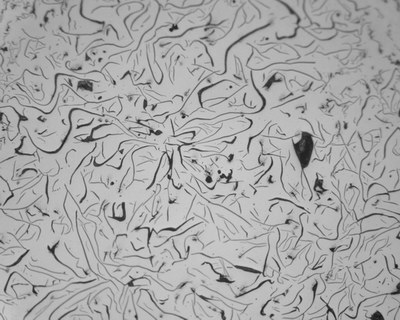

Lub graphite yuav siv sij hawm nyob rau hauv cov duab ntawm ib tug peb-dimensional flake. Nyob rau hauv ob qhov ntev, raws li ib tug polished nto yuav tshwm nyob rau hauv ib tug microscope, cov graphite flakes tshwm li cov kab zoo. Cov lus qhia ntawm cov flakes ua raws li qhov muaj nyob rau ntawm qhov chaw; yog li ntawd, nws yog nkig. Lub xub ntiag ntawm graphite flakes ua rau Grey Hlau tau yooj yim machinable vim lawv nyiam tawg yooj yim hla cov graphite flakes. Grey hlau kuj muaj peev xwm damping zoo heev thiab yog li nws feem ntau yog siv los ua lub hauv paus rau lub tshuab cuab yeej mountings.

Mechanical Properties ntawm Grey Cam khwb cia hlau | |||||||

| Cov khoom raws li DIN EN 1561 | Ntsuas | Chav tsev | TSW-GJL-150 | TSW-GJL-200 | TSW-GJL-250 | EN-GJL-300 | EN-GJL-350 |

| EN-JL 1020 | TIAB SA 1030 | TIAB SA 1040 | EN-JL 1050 | EN-JL 1060 | |||

| Tensile zog | Rm | MPA | 150-250 | 200-300 | 250-350 | 300-400 | 350-450 : kuv |

| 0.1% Yield zog | rp0, 1 | MPA | 98-165 : kuv | 130-195 : kuv | 165-228 : kuv | 195-260 : kuv | 228-285 : kuv |

| Lub zog elongation | A | % | 0, 3-0, 8 | 0, 3-0, 8 | 0, 3-0, 8 | 0, 3-0, 8 | 0, 3-0, 8 |

| Compressive zog | σ dB | MPa | 600 | 7 20 | 840 ua | 960 ua | 1080 |

| 0.1% Compressive zog | d0,1 ua | MPa | 195 | 260 | 325 | 390 | 455 |

| Flexural zog | SB IB | MPa | 250 | 290 | 340 | 390 | 490 ib |

| Schuifspanning | σ aB | MPa | 170 | 230 | 290 | 345 | 400 |

| Shear Stress | TtB | MPa | 170 | 230 | 290 | 345 | 400 |

| Module ntawm elasticity | E | GPa | 78–103 : kuv | 88-113 : kuv | 103-118 : kuv | 108-137 : kuv | 123-143 : kuv |

| Poisson naj npawb | v | - | 0,26 ib | 0,26 ib | 0,26 ib | 0,26 ib | 0,26 ib |

| Brinell hardness | HB | 160-190 : kuv | 180-220 : kuv | 190-230 : kuv | 200-240 Nws | 210-250 : kuv | |

| Ductility | s wb | MPa | 70 | 90 | 120 | 140 | 145 |

| Kev ntxhov siab thiab kev hloov siab | wb zd | MPa | 40 | 50 | 60 | 75 | 85 |

| Txoj Kev Ua Zog | Klc | N/mm3/2 | 320 | 400 | 480 | 560 | 650 |

| Qhov ntom | g/cm3 | 7,10 ib | 7,15 ib | 7,20 ib | 7,25 ib | 7,30 ib | |

Qib sib npaug ntawm Grey Cast Iron | ||||||||

| AISI | W-stoff | DIN | BS | SS | AFNOR | UNE / IHA | JIS | UNI |

| A48-20B | 0.6010 ib | GG-10 | Qib 100 | 0110-00 Nws | - | - | FC 100 | G 10 |

| A48-25B | 0.6015 ib | GG-15 | Qib 150 | 0115-00 Nws | Ft 15 D | FG 15 | FC 150 | G 15 |

| A48-30B | 0.6020 ib | GG-20 | Qib 200 | 0120-00 Nws | Ft 20 D | FG 20 | FC 200 | G 20 |

| A48-40B | 0.6025 ib | GG-25 | Qib 250 | 0125-00 Nws | Ft 25 D | FG 25 | FC 250 | G 25 |

| A48-45B | 0.6030 ib | GG-30 | Qib 300 | 0130-00 Nws | Ft 30 D | FG 30 | FC 300 | G 30 |

| A48-50B | 0.6035 ib | GG-35 | Qib 350 | 0135-00 Nws | Ft 35 D | FG 35 | SIB 350 | G 35 |

| A48-60B | 0.6040 ib | GG-40 | Qib 400 | 0140-00 Nws | Ft 40 D | - | FC 40 | - |

| 3 2510 | GTS-35 | B340/12 | 0815-00 Nws | MN 35-10 | - | HWV 330 | - | |

| A220-40010 | 0.8145 ib | GTS-45 | P440/7 | 0852-00 Nws | MN 450 | - | FCMP 440/490 | GMAW 45 |

| A220-50005 | 0.8155 ib | GTS-55-04 | P510/4 | 0854-00 Nws | MP 50-5 | - | TIAB SA 490 | GMN 55 |

| A220-70003 | 0.8165 ib | GTS-65-02 | P570/3 | 0856-00 Nws | NWS 650-3 | - | TIAB SA 590 | ZPO 65 |

| A220-70003 | - | GTS-65 | P570/3 | ib 0858 | MN 60-3 | - | TSI 540 | - |

| A220-80002 | 0.8170 ib | GTS-70-02 | P690/2 | 0862-00 Nws | MN 700-2 | - | TIAB SA 690 | ZPO 70 |

Resin Coated Sand Casting Hlau thiab Alloys | |

| Hlau & Alloys | Nrov Qib |

| Grey Cam khwb cia hlau | GG10-GG40; GJL-100 ~ GJL-350; |

| Ntiv nplhaib (Nodular) Cam khwb cia hlau | GGG40 ~ GGG80; GJS-400-18, GJS-40-15, GJS-450-10, GJS-500-7, GJS-600-3, GJS-700-2, GJS-800-2 |

| Austempered Ductile Hlau (ADI) | EN-GJS-800-8, EN-GJS-1000-5, EN-GJS-1200-2 |

| Carbon Steel | C20, C25, C30, C45 |

| Hlau alloy | 20Mn, 45Mn, ZG20Cr, 40Cr, 20Mn5, 16CrMo4, 42CrMo, 40CrV, 20CrNiMo, GCr15, 9Mn2V |

| Stainless hlau | Ferritic Stainless hlau, Martensitic Stainless hlau, Austenitic Stainless hlau, nag lossis daus Hardening Stainless hlau, Duplex Stainless hlau |

| Aluminium Alloys | Txuj: ASTM A356, ASTM A413, ASTM A360 |

| Brass / Copper-based Alloys | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 |

| Txuj: ASTM, SAE, AISI, GOST, DIN, EN, ISO, thiab GB | |

Kev Cai Casting Hlau Casting Khoom