CNC Machining Factory

Precision machining yog cov txheej txheem ntawm kev txiav cov hlau ua kom lawv haum rau cov neeg siv kawg daim ntawv thov thiab kev ua haujlwm. Feem ntau ntawm cov txheej txheem machining niaj hnub no yog ua los ntawm Computer Numerical Control, CNC, uas siv cov khoos phis tawj los tswj kev txav thiab kev ua haujlwm ntawm cov mills, lathes, thiab lwm yam tshuab txiav. Txoj kev no ntawm precision manufacturing, tseem hu ua CNC machining, plays lub luag hauj lwm tseem ceeb nyob rau hauv niaj hnub manufacturing industriy, tshwj xeeb tshaj yog rau ib co machining qhov chaw ntawm high precision.

Rau qee qhov kev siv, tsuas yogcastingslos yog forgings yam tsis muaj machining tuaj yeem ncav cuag qhov kev cia siab thiab qhov yuav tsum tau ua. Txawm li cas los xij, rau feem ntau qhov teeb meem, lub machining yog xav tau kom phim tus neeg siv khoom tshwj xeeb specifications thiab kom paub tseeb tias covtiav hlau qhov chawtuaj yeem ua haujlwm zoo nrog lwm qhov chaw. Txawm rau covpeev casting qhov chaw, uas muaj ntau qhov zoo dua thiab qib siab dua li lwm cov txheej txheem hlau, tseem xav tau cov txheej txheem machining ntxiv.

Los xyuas kom meej qhov zoo thiab precision ntawm tiavmachining qhov chaw, cov kev pab cuam hauv computer yog qhov tseem ceeb. Lub Computer Aided Design, uas yog hu ua CAD luv luv, thiab Computer Aided Manufacturing, hu ua CAM, yog ob qho tib si siv los ua cov kev pab cuam los muab cov lus qhia ntxaws txog txhua kauj ruam ntawm cov txheej txheem machining. Cov kev pab cuam xws li SolidWorks, ProE thiab UG tsim cov qauv 3D nthuav dav heev.

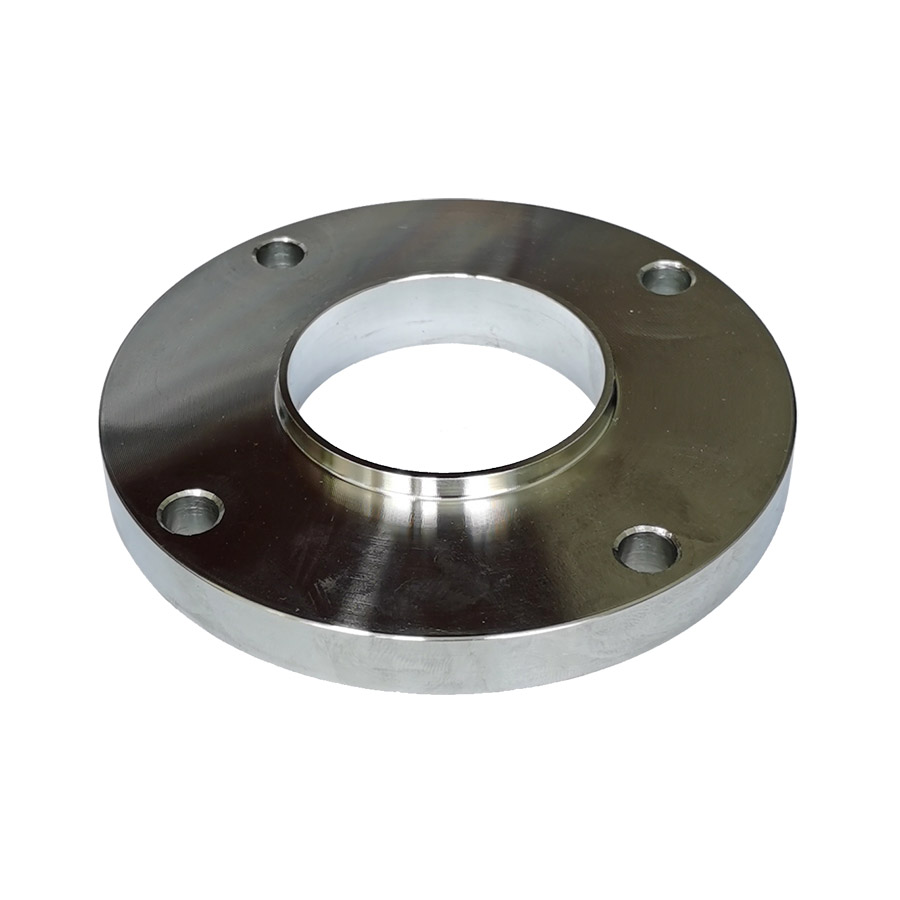

Ua tsaug rau cov tshuab CNC siab heev thiab 4 axis machining chaw ntawm ob hom kab rov tav thiab ntsug, RMC tshwj xeeb hauv kev tsim OEM kev cai machining qhov chaw nrog machining chaw, CNC tshuab thiab lwm yam cuab yeej tshwj xeeb raws li ib tus neeg siv khoom kos duab nrog cov kev cai nruj nruj thiab qhov roughness. Cov castings ntawm ferrous thiab non-ferrous hlau yog machined ntawm pebmachining Hoobkas, uas tuaj yeem pab peb muaj txiaj ntsig zoo hauv kev tswj cov nqi thiab zoo.

CNC Machining txheej txheem

Vertical Machining Center

Dab tsi peb tuaj yeem ua tiav los ntawm CNC Machining

| Cov chaw | Ntau | Qhov Loj | Muaj peev xwm txhua xyoo | Qhov tseeb |

| Vertical CNC Machining Center (VMC) | 48set ib | 1500mm × 1000mm × 800mm | 6000 tons / xyoo lossis 300000 daim ib xyoos twg | ± 0.005 |

| Kab rov tav CNC Machining Center (VMC) | 12 sets | 1200mm × 800mm × 600mm | 2000 tons / xyoo lossis 100000 daim ib xyoos twg | ± 0.005 |

| CNC tshuab | 60 sets | Max tig dia. φ600 hli | 5000 tons / xyoo lossis 600000 daim ib xyoos twg |

Machining Cheebtsam rau Hydraulic

Hom Hlau & Alloys Machined ntawm Peb Lub Tuam Txhab Machining

• Grey Cam khwb cia hlau

• Cov Hlau Casting

• Carbon Steel los ntawm cov pa roj carbon tsawg, nruab nrab carbon steel thiab siab carbon steel.

• Steel Alloys los ntawm cov qib txheem mus rau qib tshwj xeeb raws li kev thov.

• Aluminium, Zinc thiab lawv cov alloys

• tooj dag thiab tooj liab

• Stainless Hlau, Duplex Stainless Hlau

• Wear-resistant Steel, Corrosion-resistant Steel, Kub-resistant Steel.

• Hlau Profiles thiab Aluminium Profiles

• Alloy Forgings

Precision Machining

Dab tsi Machining txheej txheem peb tuaj yeem ua

Cov txheej txheem machining muaj nyob ntawm RMC CNC machining Hoobkas yog Turing, Facing, tho txawv, Milling, Drilling, Planning, Shaping, Grooving, Ntsej Muag Sib Tsoo, Cylindrical Sib Tsoo, Honing, Iav Hobbing, Threading, Lapping, Tapping ... thiab lwm yam.

- Honing

Cov txheej txheem no siv honing qhov diameters li ntawm 0.8 hli mus rau 100 hli thiab muaj qhov tob txog li 280 hli. Lub linear kam rau ua yog 0.001 hli, roundness ntawm 0.0005 hli, thiab ncaj ntawm 0.0005 hli. Qhov saum npoo tiav yog Ra 0.05 μm. Kab rov tav thiab ntsug honing tshuab yog siv thiab suav nrog ib leeg-spindle, ntxaib-spindle, thiab rau-spindle.

- Tig

Qhov no yog txheej txheem ntawm ib qho taw tes txiav ntawm hardened pieces. Peb cov txheej txheem nyuaj tig tuaj yeem tshuab qhov nyuaj nrog qhov nyuaj tshaj 58 HRC tom qab kev kho cua sov, qhov siab tshaj plaws tig txoj kab uas hla ntawm 26 hli, tig ntev mus txog 100 hli, qhov ntev ntev ntawm 0.005 hli, thiab roughness Ra0.2μm.

- Sib tsoo ntawm OD thiab ID

Cov txheej txheem no ua rau peb siv lub tshuab shafts nrog txoj kab uas hla nrog 750 hli, ntev li ntawm 1000 hli, roundness ntawm 0.0004 hli, thiab cylindricity ntawm 0.001 hli. Sab hauv qhov muaj li ntawm 3 hli mus rau 100 hli.

- Deburring

RMC lub peev xwm deburring muaj xws li electrochemical machining, thermal zog txoj kev, thiab abrasive flow machining. Cov no yog siv rau hydraulic, automotive, thiab aerospace Cheebtsam nrog hla qhov thiab complex sab hauv kab noj hniav kom tau raws li nruj deburring yuav tsum.

- OD Centerless sib tsoo

Qhov no yog siv rau shafts nrog txoj kab uas hla nrog 200 hli, ntev nrog 400 hli, txoj kab uas hla ntawm 0.001 hli, cylindricity txog li 0.0005 hli. Nws muaj rau ob qho tib si los ntawm kev pub thiab infeed.

Kab rov tav Machining Center

CNC Machining Rhiav

Cov cuab yeej zoo-Organized Peb cia siab rau CNC Precision Machining

CNC Machining Rhiav

Precision Machining txheej txheem

CNC tshuab

Machining Factory

Vertical Machining Center

Kab rov tav Machining Center

Kab rov tav Machining Center

CNC Drilling

Machining Rhiav

CNC Machining Service

Precision Machining Service

Machining Center

Kev siv ntawm CNC Machining Parts

Peb cov khoom siv thoob plawskev lag luamxws li automotive, hydraulics, railway freight tsheb, hnyav luag hauj lwm tsheb, logistics khoom, yeeb nkab thiab twj tso kua mis, roj thiab roj, thiab cov khoom ua liaj ua teb.

| • Tsheb ciav hlau | • Cov khoom siv logistics |

| • Cov Tsheb Loj | • Cov khoom siv ua liaj ua teb |

| • Automotive | • Hydraulic |

| • Cov khoom siv hauv tsev | • Cav Systems |

Cov khoom siv hlau ntawm CNC Precision Machining

Ntau tshaj CNC Machining

Raws li ib qho kev daws teeb meem ib qho chaw muab kev pabcuam thiab ua tiav cov khoom xa tuaj rauxuab zeb castings, peev castings, forgings thiab machining, peb kuj muajkev pabcuamntawm kev kho cua sov, kev kho deg nrog kev ntseeg tau thiab yooj. Peb cov engineers khaws lawv lub qhov muag ntawm cov txheej txheem tsim los ntawm cov qauv tsim rau cov khoom tiav, nrog rau cov lus pom zoo los ntawm cov neeg siv khoom. Cov neeg siv khoom cia siab rau peb rau kev tsim qauv thiab kev txhawb nqa engineering, cov ntaub ntawv thiab kev tsim khoom txhawb nqa txog cov khoom thiab cov kev qhia tshwj xeeb. Peb muaj peev xwm ua tau sai sai hauv tsev thiab kuaj cov khoom hauv tsev, NDT, vuam, thiab kev kho cua sov.

Yog li ntawd, tej yam uas peb yuav ua tau yog kev qhia thiab ib tug nres:

- Kev pabcuam:Cov qauv tsim, Tus nqi qis tshaj tawm, kev tsim khoom thiab qauv qauv, qauv, ntau lawm, kev xa khoom, kev pabcuam tomqab muag.

- Casting thiab Forming: Kev nqis peev Casting, Sand Casting, Lub ntiajteb txawj nqus tuag Casting, Siab Siab Tuag Casting,Plhaub Molding Casting, Forging, Precision Machining thiab Hlau Fabrications.

- Kev kho cua sov:Quenching, Tempering, Normalizing, Annealing, Carburization, Nitrotion

- Kev kho deg:Anodizing, Zinc-plating, Polising, GeoMet, Zintek .... thiab lwm yam

- Kev pabcuam kuaj:Chemical Composition, Mechanical Properties, Fluorescent lossis Magnetic Penetration Inspections (FPI, MPI), X-rays, Ultrasonic Test

Yog xav paub ntxiv txog yuav ua li cas peb tuaj yeem pab nrog koj qhov kev xav tau casting thiab machining lossis sib tham txog cov kev xaiv, tsuas yog xav tias dawbhu rau peb pab neeg engineeringhnub no.

Ductile Hlau Machining Qhov Chaw