Raws li cov txheej txheem tsim khoom yooj yim nrog keeb kwm ntawm 6000 xyoo, kev siv tshuab casting tsis tsuas yog muaj keeb kwm ntev, tab sis tib lub sijhawm nws tau nqus cov thev naus laus zis tshiab, cov ntaub ntawv tshiab thiab cov txheej txheem tshiab tsim hauv kev tshawb fawb niaj hnub hauv lub sijhawm. Peb muaj lub luag haujlwm los nqa mus rau qhov kev lag luam tsim khoom lag luam. Cov ntsiab lus hauv qab no yog qee yam ntawm peb txoj kev xav rau yav tom ntej txoj kev loj hlob ntawm cov xuab zeb casting txheej txheem.

1 Foundry thev naus laus zis tab tom txhim kho rau kev txuag hluav taws xob thiab txuag khoom

Nyob rau hauv cov txheej txheem casting ntau lawm, ib tug loj npaum li cas ntawm lub zog yog noj nyob rau hauv cov hlau smelting txheej txheem. Nyob rau tib lub sijhawm, qhov kev thov rau cov khoom siv hauv cov txheej txheem xuab zeb casting kuj zoo heev. Yog li ntawd, yuav ua li cas kom txuag tau lub zog thiab cov ntaub ntawv zoo dua yog qhov teeb meem loj uas ntsib cov nroj tsuag xuab zeb. Cov kev ntsuas uas nquag siv feem ntau suav nrog:

1) Txais cov xuab zeb moulding siab heev, core-ua technology thiab khoom siv. Hauvxuab zeb casting txheej txheem ntau lawm, kev kub siab, zoo li qub, kev txhaj tshuaj siab thiab cov cuab yeej siv cua tshuab yuav tsum tau siv ntau li ntau tau. Thiab kom deb li deb tau siv tus kheej-hardening xuab zeb,poob ua npuas ncauj casting, nqus casting thiab tshwj xeeb casting (xws lipeev casting, hlau pwm casting) thiab lwm yam technologies.

2) Xuab zeb rov qab thiab rov siv dua. Thaum nrum cov hlau tsis-ferrous hlau, hlau castings thiab steel castings, raws li qhov kub thiab txias ntawm cov xuab zeb, tus nqi rov qab ntawm mechanically regenerated qub xuab zeb tuaj yeem ncav cuag 90%. Ntawm lawv, kev sib xyaw ua ke ntawm cov xuab zeb rov ua dua tshiab thiab ntub dej rov ua dua tshiab yog txoj kev zoo tshaj plaws thiab siv tau zoo.

3) Recycling ntawm adhesives. Piv txwv li, yog tias qhov casting yog de-cored los ntawm txoj kev qhuav thiab cov nplaum tseem nyob hauv cov xuab zeb, cov txheej txheem tsim nyog tuaj yeem ua rau cov nplaum rov qab siv dua, yog li txo tus nqi ntawm cov nplaum.

4) Regeneration ntawm pwm thiab pwm cov ntaub ntawv.

2 Tsawg muaj kuab paug los yog tsis muaj kuab paug

Cov xuab zeb casting foundry tsim ntau cov dej khib nyiab, khib nyiab thiab plua plav thaum lub sijhawm tsim khoom. Yog li ntawd, lub foundry tsis yog tsuas yog ib tug loj lub zog noj tsev neeg, tab sis kuj yog ib tug loj pa phem qhov chaw. Tshwj xeeb tshaj yog nyob rau hauv Suav teb, muaj kuab paug nyob rau hauv foundries yog hnyav dua nyob rau hauv lwm lub teb chaws. Ntawm lawv, cov plua plav, huab cua thiab cov khoom pov tseg tawm ntawm cov xuab zeb casting nroj tsuag yog qhov hnyav tshaj plaws. Tshwj xeeb tshaj yog nyob rau xyoo tas los no, Tuam Tshoj txoj cai tiv thaiv ib puag ncig tau dhau los ua nruj dua, thiab cov chaw tsim khoom yuav tsum tau siv cov kev ntsuas zoo los tswj cov pa phem. Yuav kom ua tiav ntsuab thiab huv si ntawm xuab zeb casting, ntsuab inorganic binders yuav tsum tau siv ntau li ntau tau, los yog tsawg dua los yog tsis muaj binders yuav tsum tau siv. Ntawm cov xuab zeb casting txheej txheem tam sim no koom nrog, ploj ua npuas ncauj casting, V txheej txheem casting thiab sodium silicate xuab zeb casting yog ib puag ncig tus phooj ywg. Vim tias poob ua npuas ncauj casting thiab V txheej txheem casting siv cov xuab zeb qhuav qauv uas tsis tas yuav tsum tau binders, thaum sodium silicate xuab zeb casting siv cov organic binders.

3 Ntau qhov loj thiab geometrical raug ntawm castings

Nrog rau txoj kev loj hlob ntawm precision forming txheej txheem ntawm casting blanks, lub gemometical thiab dimensional raug ntawm ib feem txoj kev yog tsim los ntawm ze li ntawm net puab txoj kev mus rau net shape forminig, uas yog, yuav luag tsis muaj margin forming. Qhov sib txawv ntawm qhov casting dawb paug thiab qhov yuav tsum tau ua yog tau txais me me thiab me me. Tom qab qee qhov blanks tau tsim, lawv tau mus txog lossis mus txog qhov kawg ntawm cov duab thiab qhov loj ntawm cov khoom, thiab tuaj yeem sib dhos ncaj qha tom qab sib tsoo.

4 Tsawg los yog tsis muaj qhov tsis xws luag

Lwm qhov taw qhia ntawm casting roughness thiab qhov chaw tsim theem yog tus naj npawb, qhov loj thiab kev puas tsuaj ntawm qhov tsis xws luag casting. Vim tias qhov kub ua haujlwm thiab cov txheej txheem hlau casting yog qhov nyuaj heev thiab cuam tshuam los ntawm ntau yam, qhov tsis xws luag casting yog qhov nyuaj rau zam. Txawm li cas los xij, ob peb lossis tsis muaj qhov tsis xws luag yog cov qauv yav tom ntej. Muaj ntau ntau yam kev ua tau zoo:

1) Siv cov cuab yeej siv siab heev los ua kom qhov ntom ntom ntawm cov qauv hlau thiab nteg lub hauv paus kom tau txais cov suab nrov.

2) Siv casting simulation software simulate qhov tseeb casting txheej txheem nyob rau hauv lub tsim theem ua ntej. Raws li cov txiaj ntsig simulation, cov txheej txheem tsim tau ua kom zoo kom paub txog kev ua tiav ntawm ib zaug molding thiab pwm sim.

3) Txhim kho cov txheej txheem saib xyuas thiab ua haujlwm nruj me ntsis raws li cov lus qhia ua haujlwm tau txiav txim siab.

4) Txhim kho qhov kev ntsuam xyuas tsis muaj kev puas tsuaj hauv cov txheej txheem tsim khoom, nrhiav cov khoom seem hauv lub sijhawm thiab ua raws li kev kho thiab txhim kho kev ntsuas.

5) Txiav txim siab qhov tseem ceeb ntawm qhov tsis xws luag los ntawm kev tshawb fawb thiab kev ntsuam xyuas ntawm kev nyab xeeb thiab kev ntseeg siab ntawm cov khoom.

5 Lub teeb yuag ntawm castings.

Hauv kev tsim cov neeg caij tsheb,tsheb thauj khoom, thiab lwm yam khoom siv tsheb thauj mus los, yuav ua li cas txo qhov hnyav ntawm qhov chaw thaum ua kom lub zog ntawm cov khoom yog ib qho kev nthuav dav. Muaj ob yam tseem ceeb kom ua tiav qhov hnyav. Ib qho yog siv cov khoom siv lub teeb, thiab lwm qhov yog txo qhov hnyav ntawm qhov chaw los ntawm cov qauv tsim ntawm cov khoom. Vimxuab zeb castingsmuaj qhov yooj yim ntawm kev tsim qauv, thiab tseem muaj ntau yam khoom siv hlau thiab cov khoom siv tshiab los xaiv, xuab zeb casting tuaj yeem ua lub luag haujlwm loj hauv kev tsim khoom hnyav.

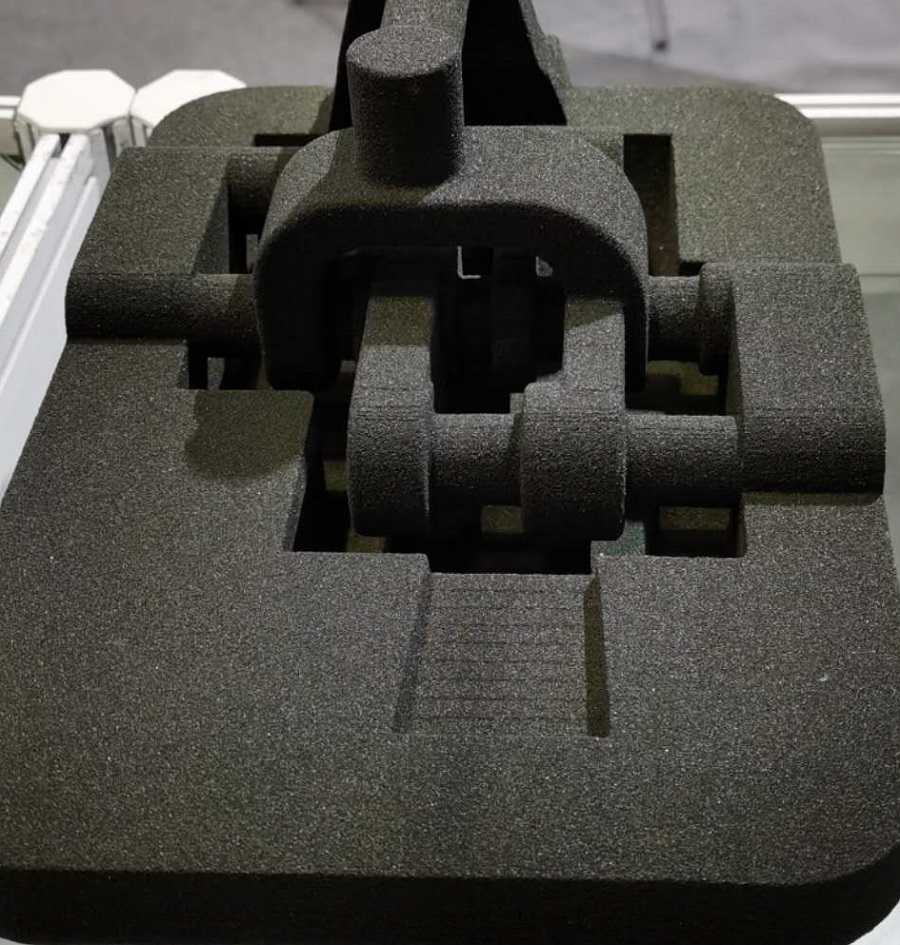

6 Kev siv cov thev naus laus zis tshiab xws li 3D luam ntawv hauv pwm ua

Nrog rau txoj kev loj hlob thiab kev loj hlob ntawm 3D tshuab luam ntawv, nws kuj yog ntau thiab ntau lug siv nyob rau hauv lub casting teb. Piv nrog rau kev tsim pwm ib txwm muaj, 3D tshuab luam ntawv tuaj yeem tsim cov pwm tsim nyog ntawm tus nqi qis. Raws li kev siv thev naus laus zis sai, 3D luam ntawv tuaj yeem muab kev ua si tag nrho rau nws qhov zoo hauv cov qauv kev sim ntau lawm thiab me me batch theem ntawm castings.

Post lub sij hawm: Dec-25-2020